Automotive spark-ignited direct-injection gasoline engines

Automotive spark-ignited direct-injection gasoline engines

Automotive spark-ignited direct-injection gasoline engines

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

484<br />

F. Zhao et al. / Progress in Energy and Combustion Science 25 (1999) 437–562<br />

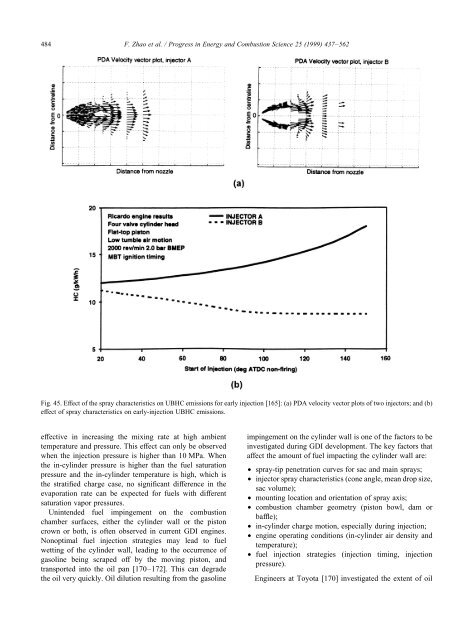

Fig. 45. Effect of the spray characteristics on UBHC emissions for early <strong>injection</strong> [165]: (a) PDA velocity vector plots of two injectors; and (b)<br />

effect of spray characteristics on early-<strong>injection</strong> UBHC emissions.<br />

effective in increasing the mixing rate at high ambient<br />

temperature and pressure. This effect can only be observed<br />

when the <strong>injection</strong> pressure is higher than 10 MPa. When<br />

the in-cylinder pressure is higher than the fuel saturation<br />

pressure and the in-cylinder temperature is high, which is<br />

the stratified charge case, no significant difference in the<br />

evaporation rate can be expected for fuels with different<br />

saturation vapor pressures.<br />

Unintended fuel impingement on the combustion<br />

chamber surfaces, either the cylinder wall or the piston<br />

crown or both, is often observed in current GDI <strong>engines</strong>.<br />

Nonoptimal fuel <strong>injection</strong> strategies may lead to fuel<br />

wetting of the cylinder wall, leading to the occurrence of<br />

<strong>gasoline</strong> being scraped off by the moving piston, and<br />

transported into the oil pan [170–172]. This can degrade<br />

the oil very quickly. Oil dilution resulting from the <strong>gasoline</strong><br />

impingement on the cylinder wall is one of the factors to be<br />

investigated during GDI development. The key factors that<br />

affect the amount of fuel impacting the cylinder wall are:<br />

• spray-tip penetration curves for sac and main sprays;<br />

• injector spray characteristics (cone angle, mean drop size,<br />

sac volume);<br />

• mounting location and orientation of spray axis;<br />

• combustion chamber geometry (piston bowl, dam or<br />

baffle);<br />

• in-cylinder charge motion, especially during <strong>injection</strong>;<br />

• engine operating conditions (in-cylinder air density and<br />

temperature);<br />

• fuel <strong>injection</strong> strategies (<strong>injection</strong> timing, <strong>injection</strong><br />

pressure).<br />

Engineers at Toyota [170] investigated the extent of oil