Automotive spark-ignited direct-injection gasoline engines

Automotive spark-ignited direct-injection gasoline engines

Automotive spark-ignited direct-injection gasoline engines

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

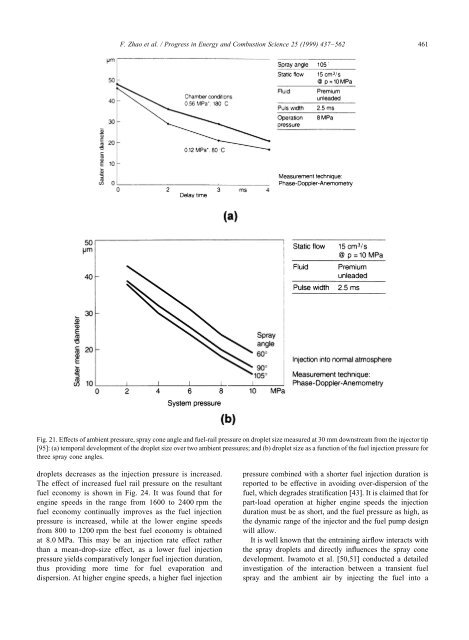

F. Zhao et al. / Progress in Energy and Combustion Science 25 (1999) 437–562 461<br />

Fig. 21. Effects of ambient pressure, spray cone angle and fuel-rail pressure on droplet size measured at 30 mm downstream from the injector tip<br />

[95]: (a) temporal development of the droplet size over two ambient pressures; and (b) droplet size as a function of the fuel <strong>injection</strong> pressure for<br />

three spray cone angles.<br />

droplets decreases as the <strong>injection</strong> pressure is increased.<br />

The effect of increased fuel rail pressure on the resultant<br />

fuel economy is shown in Fig. 24. It was found that for<br />

engine speeds in the range from 1600 to 2400 rpm the<br />

fuel economy continually improves as the fuel <strong>injection</strong><br />

pressure is increased, while at the lower engine speeds<br />

from 800 to 1200 rpm the best fuel economy is obtained<br />

at 8.0 MPa. This may be an <strong>injection</strong> rate effect rather<br />

than a mean-drop-size effect, as a lower fuel <strong>injection</strong><br />

pressure yields comparatively longer fuel <strong>injection</strong> duration,<br />

thus providing more time for fuel evaporation and<br />

dispersion. At higher engine speeds, a higher fuel <strong>injection</strong><br />

pressure combined with a shorter fuel <strong>injection</strong> duration is<br />

reported to be effective in avoiding over-dispersion of the<br />

fuel, which degrades stratification [43]. It is claimed that for<br />

part-load operation at higher engine speeds the <strong>injection</strong><br />

duration must be as short, and the fuel pressure as high, as<br />

the dynamic range of the injector and the fuel pump design<br />

will allow.<br />

It is well known that the entraining airflow interacts with<br />

the spray droplets and <strong>direct</strong>ly influences the spray cone<br />

development. Iwamoto et al. [50,51] conducted a detailed<br />

investigation of the interaction between a transient fuel<br />

spray and the ambient air by injecting the fuel into a