Automotive spark-ignited direct-injection gasoline engines

Automotive spark-ignited direct-injection gasoline engines

Automotive spark-ignited direct-injection gasoline engines

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

488<br />

F. Zhao et al. / Progress in Energy and Combustion Science 25 (1999) 437–562<br />

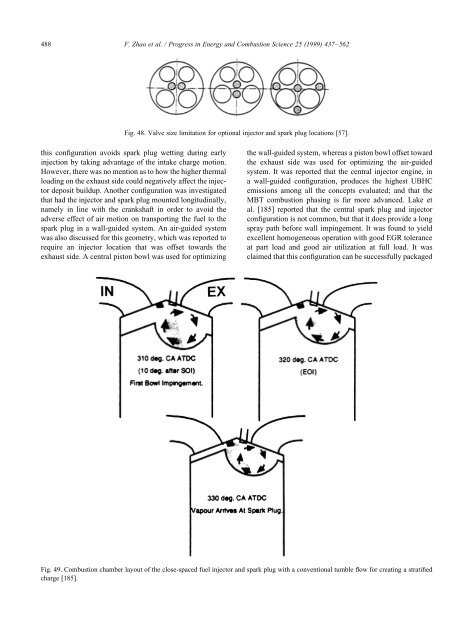

Fig. 48. Valve size limitation for optional injector and <strong>spark</strong> plug locations [57].<br />

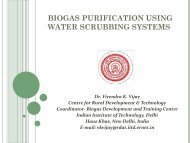

this configuration avoids <strong>spark</strong> plug wetting during early<br />

<strong>injection</strong> by taking advantage of the intake charge motion.<br />

However, there was no mention as to how the higher thermal<br />

loading on the exhaust side could negatively affect the injector<br />

deposit buildup. Another configuration was investigated<br />

that had the injector and <strong>spark</strong> plug mounted longitudinally,<br />

namely in line with the crankshaft in order to avoid the<br />

adverse effect of air motion on transporting the fuel to the<br />

<strong>spark</strong> plug in a wall-guided system. An air-guided system<br />

was also discussed for this geometry, which was reported to<br />

require an injector location that was offset towards the<br />

exhaust side. A central piston bowl was used for optimizing<br />

the wall-guided system, whereas a piston bowl offset toward<br />

the exhaust side was used for optimizing the air-guided<br />

system. It was reported that the central injector engine, in<br />

a wall-guided configuration, produces the highest UBHC<br />

emissions among all the concepts evaluated; and that the<br />

MBT combustion phasing is far more advanced. Lake et<br />

al. [185] reported that the central <strong>spark</strong> plug and injector<br />

configuration is not common, but that it does provide a long<br />

spray path before wall impingement. It was found to yield<br />

excellent homogeneous operation with good EGR tolerance<br />

at part load and good air utilization at full load. It was<br />

claimed that this configuration can be successfully packaged<br />

Fig. 49. Combustion chamber layout of the close-spaced fuel injector and <strong>spark</strong> plug with a conventional tumble flow for creating a stratified<br />

charge [185].