Automotive spark-ignited direct-injection gasoline engines

Automotive spark-ignited direct-injection gasoline engines

Automotive spark-ignited direct-injection gasoline engines

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

F. Zhao et al. / Progress in Energy and Combustion Science 25 (1999) 437–562 535<br />

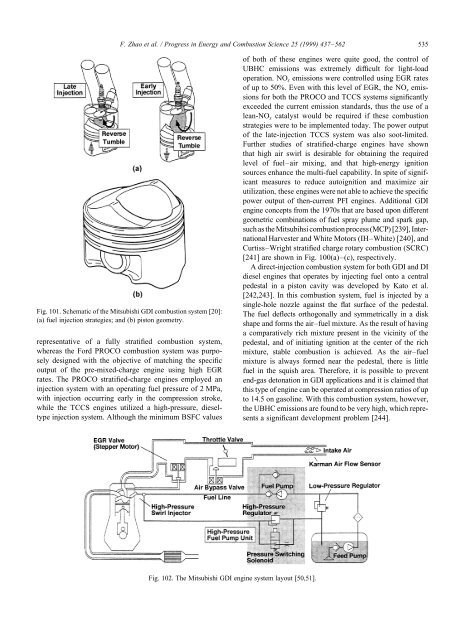

Fig. 101. Schematic of the Mitsubishi GDI combustion system [20]:<br />

(a) fuel <strong>injection</strong> strategies; and (b) piston geometry.<br />

representative of a fully stratified combustion system,<br />

whereas the Ford PROCO combustion system was purposely<br />

designed with the objective of matching the specific<br />

output of the pre-mixed-charge engine using high EGR<br />

rates. The PROCO stratified-charge <strong>engines</strong> employed an<br />

<strong>injection</strong> system with an operating fuel pressure of 2 MPa,<br />

with <strong>injection</strong> occurring early in the compression stroke,<br />

while the TCCS <strong>engines</strong> utilized a high-pressure, dieseltype<br />

<strong>injection</strong> system. Although the minimum BSFC values<br />

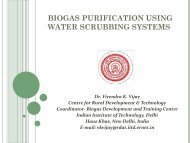

Fig. 102. The Mitsubishi GDI engine system layout [50,51].<br />

of both of these <strong>engines</strong> were quite good, the control of<br />

UBHC emissions was extremely difficult for light-load<br />

operation. NOx emissions were controlled using EGR rates<br />

of up to 50%. Even with this level of EGR, the NO x emissions<br />

for both the PROCO and TCCS systems significantly<br />

exceeded the current emission standards, thus the use of a<br />

lean-NO x catalyst would be required if these combustion<br />

strategies were to be implemented today. The power output<br />

of the late-<strong>injection</strong> TCCS system was also soot-limited.<br />

Further studies of stratified-charge <strong>engines</strong> have shown<br />

that high air swirl is desirable for obtaining the required<br />

level of fuel–air mixing, and that high-energy ignition<br />

sources enhance the multi-fuel capability. In spite of significant<br />

measures to reduce autoignition and maximize air<br />

utilization, these <strong>engines</strong> were not able to achieve the specific<br />

power output of then-current PFI <strong>engines</strong>. Additional GDI<br />

engine concepts from the 1970s that are based upon different<br />

geometric combinations of fuel spray plume and <strong>spark</strong> gap,<br />

such as the Mitsubihsi combustion process (MCP) [239], International<br />

Harvester and White Motors (IH–White) [240], and<br />

Curtiss–Wright stratified charge rotary combustion (SCRC)<br />

[241] are shown in Fig. 100(a)–(c), respectively.<br />

A <strong>direct</strong>-<strong>injection</strong> combustion system for both GDI and DI<br />

diesel <strong>engines</strong> that operates by injecting fuel onto a central<br />

pedestal in a piston cavity was developed by Kato et al.<br />

[242,243]. In this combustion system, fuel is injected by a<br />

single-hole nozzle against the flat surface of the pedestal.<br />

The fuel deflects orthogonally and symmetrically in a disk<br />

shape and forms the air–fuel mixture. As the result of having<br />

a comparatively rich mixture present in the vicinity of the<br />

pedestal, and of initiating ignition at the center of the rich<br />

mixture, stable combustion is achieved. As the air–fuel<br />

mixture is always formed near the pedestal, there is little<br />

fuel in the squish area. Therefore, it is possible to prevent<br />

end-gas detonation in GDI applications and it is claimed that<br />

this type of engine can be operated at compression ratios of up<br />

to 14.5 on <strong>gasoline</strong>. With this combustion system, however,<br />

the UBHC emissions are found to be very high, which represents<br />

a significant development problem [244].