View/Open - Scholarly Commons Home

View/Open - Scholarly Commons Home

View/Open - Scholarly Commons Home

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

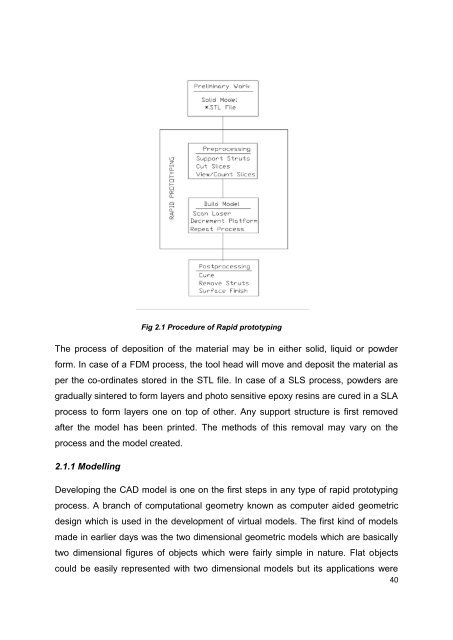

Fig 2.1 Procedure of Rapid prototyping<br />

The process of deposition of the material may be in either solid, liquid or powder<br />

form. In case of a FDM process, the tool head will move and deposit the material as<br />

per the co-ordinates stored in the STL file. In case of a SLS process, powders are<br />

gradually sintered to form layers and photo sensitive epoxy resins are cured in a SLA<br />

process to form layers one on top of other. Any support structure is first removed<br />

after the model has been printed. The methods of this removal may vary on the<br />

process and the model created.<br />

2.1.1 Modelling<br />

Developing the CAD model is one on the first steps in any type of rapid prototyping<br />

process. A branch of computational geometry known as computer aided geometric<br />

design which is used in the development of virtual models. The first kind of models<br />

made in earlier days was the two dimensional geometric models which are basically<br />

two dimensional figures of objects which were fairly simple in nature. Flat objects<br />

could be easily represented with two dimensional models but its applications were<br />

40