View/Open - Scholarly Commons Home

View/Open - Scholarly Commons Home

View/Open - Scholarly Commons Home

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

At the very outset of generating the tool path information, it has been found that a<br />

number of vectors which are in unsorted state are available. These vectors are not<br />

necessarily in sequence and are also not connected. Because of which the layers<br />

cannot be identified by the rapid prototyping machine. These vectors need to be<br />

arranged in a form which can be then easily read by a rapid prototyping machine.<br />

The triangular facets containing a number of vectors in the same plane are<br />

connected with straight lines to each other.<br />

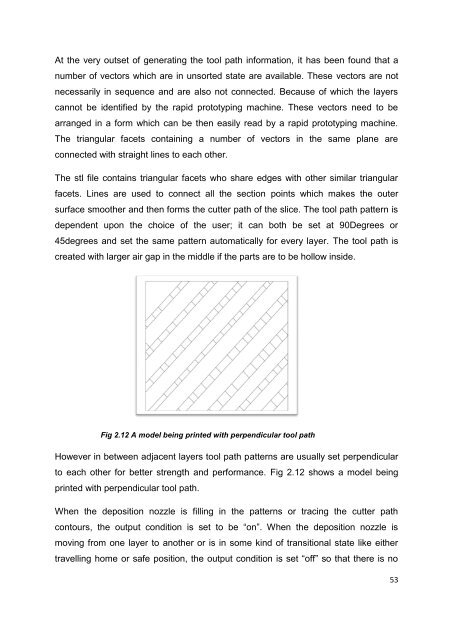

The stl file contains triangular facets who share edges with other similar triangular<br />

facets. Lines are used to connect all the section points which makes the outer<br />

surface smoother and then forms the cutter path of the slice. The tool path pattern is<br />

dependent upon the choice of the user; it can both be set at 90Degrees or<br />

45degrees and set the same pattern automatically for every layer. The tool path is<br />

created with larger air gap in the middle if the parts are to be hollow inside.<br />

Fig 2.12 A model being printed with perpendicular tool path<br />

However in between adjacent layers tool path patterns are usually set perpendicular<br />

to each other for better strength and performance. Fig 2.12 shows a model being<br />

printed with perpendicular tool path.<br />

When the deposition nozzle is filling in the patterns or tracing the cutter path<br />

contours, the output condition is set to be “on”. When the deposition nozzle is<br />

moving from one layer to another or is in some kind of transitional state like either<br />

travelling home or safe position, the output condition is set “off” so that there is no<br />

53