- Page 1 and 2:

Code Manual for CONTAIN 2.0: A Comp

- Page 3:

ABSTRACT The CONTAIN 2.0 computer c

- Page 6 and 7:

TABLE OF CONTENTS (CONTINUED) 4.0 A

- Page 8 and 9:

R O TABLE OF CONTENTS (CONTINUED) 6

- Page 10 and 11:

TABLE OF CONTENTS (CONTINUED) 9.1.3

- Page 12 and 13:

TABLE OF CONTENTS (CO NTINUED) 13.0

- Page 14 and 15:

TABLE OF CONTENTS (CONTINUED) 14.2.

- Page 16 and 17:

TABLE OF CONTENTS (CONTINUED) 16.3.

- Page 18 and 19:

TABLE OF CONTENTS (CONCLUDED) C.2Va

- Page 20 and 21:

LIST OF FIGURES (CO NTINUED) Figure

- Page 22 and 23:

LIST OF FIGURES (CONCLUDED) Figure

- Page 24 and 25:

LIST OF TABLES (CONCLUDED) Table 9-

- Page 27 and 28:

1.0 INTRODUCTION The CONTAIN code i

- Page 29 and 30:

. respond under accident conditions

- Page 31 and 32:

This code manual includes documenta

- Page 33 and 34:

The intent of this document is to p

- Page 35:

Table 1-3 Major New Models and Feat

- Page 38 and 39:

Deposition/ Agglomeration Rates Hea

- Page 40 and 41:

For completeness, the environment o

- Page 42 and 43:

ilobal Loop zstart I Input * Loed N

- Page 44 and 45:

Table 2-1 lists the internal timest

- Page 46 and 47:

where p is the structure density, C

- Page 48 and 49:

material definitions are given in t

- Page 50 and 51:

water vapor, noncondensable gases (

- Page 52 and 53:

2.7 Aerosol Behavior Events occurri

- Page 54 and 55:

In addition to these models, fissio

- Page 56 and 57:

2.10 Heat and Mass Transfer Through

- Page 58 and 59:

diffusion of water and the released

- Page 60 and 61:

primary system through a large ice

- Page 62 and 63:

Gas Liquid ● argon ● nitrogen

- Page 64 and 65:

Table 3-2 References for CONTAIN Ma

- Page 66 and 67:

● A common reference temperature,

- Page 68 and 69:

where u$T,P) = h$T) = ~~TcP,f(T)dT

- Page 70 and 71:

Table 3-3 The Coefficients Aij in E

- Page 72 and 73:

To ensure that the extrapolation ha

- Page 74 and 75:

4. AssumWion of saturated intermedi

- Page 76 and 77:

output after a run is completed, th

- Page 79 and 80:

4.0 ATMOSPHERIVPOOL THERMODYNAMIC A

- Page 81 and 82:

o 0 *0-0 o +F-ooo 0000 Atmosphere G

- Page 83 and 84:

Am An HW ❑ Ht AI * HI= Hb Figure

- Page 85 and 86:

connected to the respective cells.

- Page 87 and 88:

A side-connected path is defined as

- Page 89 and 90:

4.3 ~ tion The flow modeling option

- Page 91 and 92:

FLOW option for overcoming the gas

- Page 93 and 94:

Table 4-2 Conservation of Momentum

- Page 95 and 96:

4.4.3 User-Specified Flow Rates The

- Page 97 and 98:

4.4.5 Gravitational Head Modeling T

- Page 99 and 100:

gas center-of-volume elevations, in

- Page 101 and 102:

crossover parameter y always select

- Page 103 and 104:

interface, since in CONTAIN materia

- Page 105 and 106:

where dmi ~ Table 4-3 Conservation

- Page 107 and 108:

where Table 4-3 Conservation of Mas

- Page 109 and 110:

Table 4-4 Conservation of Energy Eq

- Page 111 and 112:

Table 4-5 Conservation of Mass Equa

- Page 113 and 114:

Table 4-6 Conservation of Energy Eq

- Page 115 and 116:

architecture. A gas-pool equilibrat

- Page 117 and 118:

Finally, the mass transfer rate of

- Page 119 and 120:

where Ap~jis the area of the atmosp

- Page 121 and 122:

The FIX-FLOW option may be useful i

- Page 123 and 124:

exit losses and other fictional los

- Page 125:

. Pressure: where Pi = 2 k=l Table

- Page 128 and 129:

CCIS are modeled through an embedde

- Page 130 and 131:

~ Boiling \t/ o 0: O.” 0°0000 .O

- Page 132 and 133:

the pool layer should lie on top of

- Page 134 and 135:

modeled will include the scrubbing

- Page 136 and 137:

ebar using the RBRCOMP keyword. Con

- Page 138 and 139:

aerosol release model. The allowabl

- Page 140 and 141:

Keyword Chemical Symbol Table 5-4 M

- Page 142 and 143:

The coolant pool layer is unique in

- Page 144 and 145:

water and regarding heat transfer a

- Page 146 and 147:

options is directed to the fwst nod

- Page 148 and 149:

5.6.2 External Lower Cell Material

- Page 150 and 151:

CONTAIN Code Main Modules CONTAIN I

- Page 152 and 153:

5.7.5 Restrictions in Mass and Ener

- Page 154 and 155:

Both gas-phase and condensed-phase

- Page 156 and 157:

decay power calculated in the DECAY

- Page 158 and 159:

5.8.15 Energy Conservation (2.3.12

- Page 160 and 161:

4. 5. 6. 7. 8. 9. imposed on it by

- Page 163 and 164:

6.0 DIRECT CONTAINMENT HEATING (DCH

- Page 165 and 166:

● ● ● “. . . . . ● ☞✍

- Page 167 and 168:

evolve independently of the other d

- Page 169 and 170:

The combined mass flow rate of gas

- Page 171 and 172:

where ,=W Ipgu+wi Note that when al

- Page 173 and 174:

‘ig,i,k _ — — ~‘jiwji$ ‘g

- Page 175 and 176:

entering directly into the atmosphe

- Page 177 and 178:

airborne particles can be neglected

- Page 179 and 180:

1. Conventional atmospheric source

- Page 181 and 182:

ecommended that the user review Ref

- Page 183 and 184:

The heat transfer coefficient betwe

- Page 185 and 186:

other versions of the Whalley-Hewit

- Page 187 and 188:

6.2.10.2 Entrained Fraction Correla

- Page 189 and 190:

and [) y+l y+l f(y) = yo”s ~ 2 (y

- Page 191 and 192:

ecause the desired fraction of debr

- Page 193 and 194:

pdv; NWe=— C! (6-71) where NW.is

- Page 195 and 196:

Equations (6-73) and (6-74) may all

- Page 197 and 198:

dmd’ ,, ~ +[+” rpv,s [1 ‘t en

- Page 199 and 200:

Tin = v.=— g,ln Z ‘g,ji6jiTg,jc

- Page 201 and 202:

An important aspect of the CONTAIN

- Page 203 and 204:

6.3.6 TOF/KU Trapping Model Like th

- Page 205 and 206:

whose default value is 0.32, p~jis

- Page 207 and 208:

The flight time and average velocit

- Page 209 and 210:

If slip is ignored completely, then

- Page 211 and 212:

Zr +2HZ0 + Z@z+2Hz L Fe+ H20 “ zr

- Page 213 and 214:

The Reynolds and Schmidt dimensionl

- Page 215 and 216:

D H20 = 4.40146 X 10-6 (T~~)2334 P

- Page 217 and 218:

.. 1-exp -~ = 0.5 [} ‘d where t~o

- Page 219 and 220:

AN~~, = N& 1- exp -— ‘re [{IIAt

- Page 221 and 222:

(AI-120)i,n= (~)~oAtC Am,j,.,,=-((A

- Page 223 and 224:

where ~~,i,. = (AO&hO~P&i,n) + (AH2

- Page 225 and 226:

calculated intercell mass flow rate

- Page 227 and 228:

The total radiative energy loss fro

- Page 229:

The velocity for non-airborne debri

- Page 232 and 233:

UK ~ DSolid Aerosol Water [ A Spray

- Page 234 and 235:

● particle scrubbing from gases v

- Page 236 and 237:

too small by evaporation of water.

- Page 238 and 239:

(7-3) where d(&(t)/dt is the time r

- Page 240 and 241:

This constraint thus reduces the nu

- Page 242 and 243:

particles can combine at a time. Th

- Page 244 and 245:

Except when they include significan

- Page 246 and 247:

Table 7-1 Comparison Between Fixed-

- Page 248 and 249:

Figure 7-3. Model for Water Condens

- Page 250 and 251:

The condensation Reference Pru78: r

- Page 252 and 253:

DiffusioDhoresi$. When water conden

- Page 254 and 255:

the user may specify these paramete

- Page 256 and 257:

The settling area ~ is the sum of a

- Page 258 and 259:

The effective cylindrical diameter

- Page 260 and 261:

where St is the Stokes number, the

- Page 262 and 263:

100 1 ()-1 10-2 1()-3 10-4 ‘\ Tot

- Page 264 and 265:

and Potential Flow: ELP E ll,p = =

- Page 266 and 267:

The efilciency E of a spray drop ch

- Page 268 and 269:

with enhanced scrubbing) or a small

- Page 270 and 271:

As an example of difficulties that

- Page 272 and 273:

,. - 137c~ / \ P- w 137M Ba 1 137Ba

- Page 274 and 275:

user. From this information, the co

- Page 276 and 277:

No. 7 No. 8 No. 9 No. 10 No. 11 No.

- Page 278 and 279:

~- ~- No. 19 l~R” —> 106Rh~ 106

- Page 280 and 281:

No. 28 No. 29 No. 30 No. 31 No. 32

- Page 282 and 283:

with the host. In such cases, the f

- Page 284 and 285:

103Rhbranch as in the second chain

- Page 286 and 287:

and B2, respectively, differing onl

- Page 288 and 289:

Table 8-3 Fission Product Library -

- Page 290 and 291:

inventory and for time-dependent so

- Page 292 and 293:

[Lee80] Note that array space for t

- Page 294 and 295:

I GAS UC Atmosphere Heat +%.OOO 00

- Page 296 and 297:

where t is the problem time in seco

- Page 298 and 299:

where V~ is the drop volume, which

- Page 300 and 301:

supplied by the library. Such inven

- Page 302 and 303:

The governing equation for the chan

- Page 304 and 305:

s DFB is assumed to occur whenever

- Page 306 and 307:

The chemical reactions that occur d

- Page 308 and 309:

up before ignition occurs. For exam

- Page 310 and 311:

delay factor is too small, the tota

- Page 312 and 313:

The deflagration model assumes that

- Page 314 and 315:

The above correlations assume only

- Page 316 and 317:

to occur in the bum model at a reas

- Page 318 and 319:

where At~,is the remaining bum time

- Page 320 and 321:

Specifically, for DFB to occur, the

- Page 322 and 323:

where NtOti= N~ + N~o + ~ is the to

- Page 324 and 325:

wheres, is the user-specified spont

- Page 326 and 327:

—’ - ● *4 / hMl Outgassing St

- Page 328 and 329:

prior to CONTAIN 1.2, there is cons

- Page 330 and 331:

except for the error introduced by

- Page 332 and 333:

0.1 0.08 0.06 0.04 ~ 0.02 h G o s .

- Page 334 and 335:

Nk = ~BLcp,BLABL h = kB~N~u/L (10-1

- Page 336 and 337:

unsubmerged surface of the structur

- Page 338 and 339:

‘=4Hpi-Hb’iF$l (10-15) e where

- Page 340 and 341:

to simulate forced convection throu

- Page 342 and 343:

10.1.3 Generalized Gas-Structure Co

- Page 344 and 345:

Note that the default correlations

- Page 346 and 347:

Because the heat and mass transfer

- Page 348 and 349:

0.01 0.001 0.0001 0.00001 temperatu

- Page 350 and 351:

0.01 0.001 0.0001 0.00001 ~emperatu

- Page 352 and 353:

default correlations with ones of t

- Page 354 and 355:

The film tracking model is discusse

- Page 356 and 357:

this limit would correspond to a fi

- Page 358 and 359:

follows the standard recommendation

- Page 360 and 361:

In Equation (10-54) the relation 6

- Page 362 and 363:

where N is the number of the surfac

- Page 364 and 365:

X= XO-b At, AT (lo-66) where X“is

- Page 366 and 367:

The ernissivity of each of the abov

- Page 368 and 369:

The term ~ in Equation (10-80) is t

- Page 370 and 371:

coolant subcooling. The various cor

- Page 372 and 373:

If boiling is occurring at the inte

- Page 374 and 375:

‘TL.eid,s.b = ATbid + 8 AT,ub (10

- Page 376 and 377:

Concrete Air Figure 10-8. Cylindric

- Page 378 and 379:

where k is the thermal conductivity

- Page 380 and 381:

T 2,eff = T2 h I,eff = hlz whereas

- Page 382 and 383:

extrapolated temperature as defined

- Page 384 and 385:

Distance ~ ~ Surface Node ~ Nodei F

- Page 386 and 387:

The interface temperature Oihas sti

- Page 388 and 389:

to be reduced in proportion to this

- Page 390 and 391:

fde, TAPE17, to the effect that the

- Page 392 and 393:

The outgassing of evaporable water

- Page 394 and 395:

Gas Film Boundary Layer Bulk \& I A

- Page 396 and 397:

interface temperature. Note that co

- Page 398 and 399:

● heat transfer between the atmos

- Page 400 and 401:

Reactor Pressure Vessel Drywell Sou

- Page 402 and 403:

Figure 11-2. CONTAIN Multi-Node Ven

- Page 404 and 405:

L“ ●LO n ‘n I ,a ,rn n I I I

- Page 406 and 407:

Table 11-1 Example Solution for Flo

- Page 408 and 409:

IDrywell Water Vapor and Gas Source

- Page 410 and 411:

—= dx — dt F Pq 1 2[pd - ‘w +

- Page 412 and 413:

Drywell, Pd Ii P(f> Pw Vent Vd =

- Page 414 and 415:

For flow from wetwell to drywell, a

- Page 416 and 417:

Aeff =4 for AP > APU where ~ is the

- Page 418 and 419:

the component hosting the fission p

- Page 420 and 421:

noncondensable gases multiplied by

- Page 423 and 424:

12.0 ENGINEERED SAFETY FEATURE MODE

- Page 425 and 426:

~ Spray Flow Path ~~ Reinforced Con

- Page 427 and 428:

Inlet Manifold Cold Side Hot Side C

- Page 429 and 430:

other than air or superheated condi

- Page 431 and 432:

Because the total heat transferred

- Page 433 and 434:

7 Plenum t Ice Compartment 1 Accumu

- Page 435 and 436:

spring or gravity-controlled motion

- Page 437 and 438:

conditions. If “citlex” does no

- Page 439 and 440:

where p~is the atmosphere gas mixtu

- Page 441 and 442:

In these equations, N~~is the drop

- Page 443 and 444:

Figure 12-8. Th,o ~b Cold Leg (Outl

- Page 445 and 446:

The capacity-rate ratio CR is defin

- Page 447 and 448:

Note that the user-specified pump m

- Page 449 and 450:

13.0 USER GUIDANCE AND PRACTICAL AN

- Page 451 and 452:

small flow areas. Also, in the mome

- Page 453 and 454:

13.2.4 Aerosol Modeling ~t. The aer

- Page 455 and 456:

~s. The heat given off by many radi

- Page 457 and 458:

concentration in the cell maybe hig

- Page 459 and 460:

In comparisons with experimental re

- Page 461 and 462:

It is normally considered inappropr

- Page 463 and 464:

0.00016 0.00014 0.00012 0.0001 8E-0

- Page 465 and 466:

13.2.9 Calculational Sequence Effec

- Page 467 and 468:

13.3.1.3 Modelin~ Stratifications.

- Page 469 and 470:

Figure 13-2. Two Thermal Siphon Nod

- Page 471 and 472:

for the Sequoyah plant given in Cha

- Page 473 and 474:

— uses CONTAIN. In any given anal

- Page 475 and 476:

0.4 0.3 0.2 0.1 (a) / ~ ..” ~ ●

- Page 477 and 478:

Table 13-1 Summary of the CONTAIN S

- Page 479 and 480:

0.4 1J- 2 6.3 d# p“ RPV (13-1) He

- Page 481 and 482:

1. Use Equation (13-1) to define z~

- Page 483 and 484:

In the standard prescription, the c

- Page 485 and 486:

as small pipes, cabling, etc. Impac

- Page 487 and 488:

esulting from homogenizing cool age

- Page 489 and 490:

equivalent to that of the liquid wa

- Page 491 and 492:

called “tarnping.” Since aeroso

- Page 493 and 494:

Co-Eiected Primarv Svstem Water. Wa

- Page 495 and 496:

.- If the initial atmosphere compos

- Page 497 and 498:

hybrid solver was not available at

- Page 499 and 500:

13.3.2.3 RPV Models. When the RPV a

- Page 501 and 502:

other governing input parameters. I

- Page 503 and 504:

and Griffith. ~i196] In addition, t

- Page 505 and 506:

several reasons, the assessment per

- Page 507 and 508:

area. It is recommended that the us

- Page 509 and 510:

800 700 600 500 400 300 200 100 0 \

- Page 511 and 512:

heat flow under conditions of nearl

- Page 513 and 514:

dumped into a layer in a short time

- Page 515 and 516:

Comments at the begiming of an inpu

- Page 517:

— cannot be modeled directly. How

- Page 520 and 521:

CELL, must follow the global input.

- Page 522 and 523:

CELL 1 && beginning of input for ce

- Page 524 and 525:

In the following input descriptions

- Page 526 and 527:

A sub-block thus can begin with a l

- Page 528 and 529:

The global CONTROL block is used to

- Page 530 and 531:

NENGV = nengv NWDUDM = nwdudm NMTRA

- Page 532 and 533:

table may be specified after the CO

- Page 534 and 535:

COMPOUND keyword. Such names need n

- Page 536 and 537:

RHOT density values, paired with th

- Page 538 and 539:

correspond to the species as they a

- Page 540 and 541:

14.2.4 Intercell Flows be considere

- Page 542 and 543:

nat the number of cell atmospheres

- Page 544 and 545:

cellfr the number of the cell from

- Page 546 and 547:

VTOPEN = vtopen TYPE = {GAS or POOL

- Page 548 and 549:

RVAREA-P the keyword for initiating

- Page 550 and 551:

NWET the number of the cell contain

- Page 552 and 553:

(NAME=aname [FLAG=iflag] X=n (x) VA

- Page 554 and 555:

keyword will result in the oversize

- Page 556 and 557:

SURTEN the surface tension of a wet

- Page 558 and 559:

newcof = 2: Coefficients are reques

- Page 560 and 561:

FINVT = (finvt) (8-5). If FGPPWR is

- Page 562 and 563:

In the input block description of t

- Page 564 and 565:

FDISTR = (fdistr) FDEVEN GRPLIM = g

- Page 566 and 567:

DIFH20 the multiplier on the mass t

- Page 568 and 569:

AHOLE1 the initial hole size in the

- Page 570 and 571:

IENFRA = ienfra AFLOW = aflow AHENF

- Page 572 and 573:

WESIG the natural logarithm of the

- Page 574 and 575:

The EDMULT keyword is useful for re

- Page 576 and 577:

PRBURN a keyword which invokes the

- Page 578 and 579:

tfac exactly “ncells”values spe

- Page 580 and 581:

14.3 Cell Level Input The cell is t

- Page 582 and 583:

a pool layer will form in the cours

- Page 584 and 585:

NSOSAT the number of safety relief

- Page 586 and 587:

GASVOL = gasvol CELLHIST n hl, area

- Page 588 and 589:

Presently, DCH and other nongaseous

- Page 590 and 591:

xmass the mass of species “oname

- Page 592 and 593:

ATMOS=3 EOI PGAS=l.0E5 TGAS=335 SAT

- Page 594 and 595:

[INIDEPTH=indpth] [MINDEPTH=rnndpth

- Page 596 and 597:

STRUC CRANK = crank OUTGAS TRANGE t

- Page 598 and 599:

kco2 eco2 QH20E = qh20e QH20B = qh2

- Page 600 and 601:

cYLHn-’E the axial length of a cy

- Page 602 and 603:

FORCOR1 =a3b3c3 d3 FORCOR2 =a4b4c4

- Page 604 and 605:

VELOCITY, REY-NUM, and NUS-FORC are

- Page 606 and 607:

whether net condensation or evapora

- Page 608 and 609:

cylinder. Here, RI is the cylinder

- Page 610 and 611:

istr hgap ICELL = icell TGAS = tgas

- Page 612 and 613:

14.3.1.5 Radiation. The radiation m

- Page 614 and 615:

eaml EOI GASWAL = gaswal GEOBL geob

- Page 616 and 617:

Table 14-1 Types of Bums Allowed fo

- Page 618 and 619:

0.0376. Thekeyword CFRMNGserves the

- Page 620 and 621:

DEBCONC the concentration of debris

- Page 622 and 623:

14.4.1. The particle size distribut

- Page 624 and 625:

14.3.1.10 Fission Product Initial C

- Page 626 and 627:

FROM = marne TO = aname “mame”

- Page 628 and 629:

The following keywords and associat

- Page 630 and 631:

LENGFT = xleng KU1 = xku 1 KU2 = xk

- Page 632 and 633:

and the DIATR4P, VELTRAP, and IL4.D

- Page 634 and 635:

(data) EOIl [CONCRETE (data) EOIl (

- Page 636 and 637:

EOI [Q235U=q235u] [Q238U=q238u] [Q2

- Page 638 and 639:

EOI EOIl T=(times) MASS=(masses) {T

- Page 640 and 641:

HT-COEF NAME olay oxopt nh xhtval h

- Page 642 and 643:

EOI EOI [USERSENS [{HXBOTCOR ahtb b

- Page 644 and 645:

RBRCOMP ometl fmfrac EOI cmass TEMP

- Page 646 and 647:

w the outside radius of the cylinde

- Page 648 and 649:

SLAGSIDE a keyword which enables th

- Page 650 and 651:

HBOILFLX = nhb dtsat bflx HBOILMUL

- Page 652 and 653:

RHOOMUL = rhomul TSOMLT = tsomlt XE

- Page 654 and 655:

DETAIL nvcons ovnam nfp ofpnam wfra

- Page 656 and 657:

into CONTAIN. The obsolete VANESA k

- Page 658 and 659:

SOURCE nso Q-VOL HT-COEF the keywor

- Page 660 and 661:

smo TMETAL = tmi TOXIDE = toi LAYER

- Page 662 and 663:

METALPWR the keyword to begin speci

- Page 664 and 665:

14.3.3 Engineered Safety Systems Th

- Page 666 and 667:

iclin iclout delev now automaticall

- Page 668 and 669:

FCFLAR the frontal area of the fan

- Page 670 and 671:

DIAMDIF the effective wire cylindri

- Page 672 and 673:

hxarea the effective heat transfer

- Page 674 and 675:

PIPE the keyword to specify a pipe

- Page 676 and 677:

EOI (oaer=na [IFLAG=ival] [AMEAN=(m

- Page 678 and 679:

SOURCE nsosfp Ofp nf HOST = nhost C

- Page 680 and 681:

with standard keywords. Thus the pr

- Page 682 and 683:

encountered. Aerosol suspended mass

- Page 684 and 685:

EOI the keyword used to terminate e

- Page 686 and 687:

[PRFLOW [{ON or OFF}]] [PRAER [{ON

- Page 688 and 689:

14.5.1.1 The TIMES Block in a Resta

- Page 690 and 691:

AEROSOL a keyword sequence to speci

- Page 693 and 694:

15.0 SAMPLE PLANT CALCULATIONS In t

- Page 695 and 696:

Table 15-1 Grand Gulf Input File (C

- Page 697 and 698:

— o1 DRYWELL t o2 ANNULUS Figure

- Page 699 and 700:

. 2 190 PO o - 170 aJ L 3 In (n a)

- Page 701 and 702:

3 0 r w.- 3 0- .- _d 120 100 80 60

- Page 703 and 704:

8 7 1 0 % :k I I i I I I I I I I 1

- Page 705 and 706:

15.2 Surry Plant In the second samp

- Page 707 and 708:

Table 15-2 Surry Input File (Contin

- Page 709 and 710:

Table 15-2 Surry Input File (Contin

- Page 711 and 712:

Table 15-2 Surry Input File (Contin

- Page 713 and 714:

Table 15-2 Surry Input File (Contin

- Page 715 and 716:

Table 15-2 Surry Input File (Contin

- Page 717 and 718:

Table 15-2 Surry Input File (Contin

- Page 719 and 720:

Table 15-2 Surry Input File (Contin

- Page 721 and 722:

Table 15-2 Surry Input File (Contin

- Page 723 and 724:

Table 15-2 Surry Input File (Contin

- Page 725 and 726:

mass= O.OOOOOe+OO 1.45045e+Ol 1.438

- Page 727 and 728:

3.05000e-01 eoi Table 15-2 Surry In

- Page 729 and 730:

concrete in the cavity and thus the

- Page 731 and 732:

500 450 400 350 300 250 200 150 100

- Page 733 and 734:

-. The amount of water boiled and e

- Page 735 and 736:

.- 1.0 0.9 0.8 0.7 0.6 0.5 0.4 0.3

- Page 737 and 738:

c .— s o .- rn (J-J K 1 0+2 10-3

- Page 739 and 740:

5.0 4.8 4.6 4.4 4.2 4.0 3.8 3.6 3.4

- Page 741 and 742:

Table 15-3 Sequoyah Input File && -

- Page 743 and 744:

Table 15-3 Sequoyah Input File (Con

- Page 745 and 746:

2.8000e+Ol 2.8000e+Ol 2.8000e+Ol en

- Page 747 and 748:

8.0500e+02 8.0650e+02 eoi feed debr

- Page 749 and 750:

eoi 1.0000e+Ol 1.0000e+Ol 1.0000e+O

- Page 751 and 752:

Table 15-3 Sequoyah Input File (Con

- Page 753 and 754:

eoi Table 15-3 Sequoyah Input File

- Page 755 and 756:

Table 15-3 Sequoyah Input File (Con

- Page 757 and 758:

Table 15-3 Sequoyah Input File (Con

- Page 759 and 760:

Table 15-3 Sequoyah Input File (Con

- Page 761 and 762:

Table 15-3 Sequoyah Input File (Con

- Page 763 and 764:

eoi 4.30918e+06 4.34125e+06 4.52691

- Page 765 and 766:

Table 15-3 Sequoyah Input File (Con

- Page 767 and 768:

eoi 1.55497e+07 1.58464e+07 1.65145

- Page 769 and 770:

Table 15-3 Sequoyah Input File (Con

- Page 771 and 772:

var-y=diatrap eoi trapping to fku &

- Page 773 and 774:

Table 15-3 Sequoyah Input File (Con

- Page 775 and 776:

Table 15-3 Sequoyah Input File (Con

- Page 777 and 778:

o 8 w s H I E 5 UP Co L I D 3’ 4

- Page 779 and 780:

Table 15-4 Sequoyah Restart Input F

- Page 781 and 782:

.. Table 15-4 Sequoyah Restart Inpu

- Page 783 and 784:

eoi dch-cell sdeven= 1.0 && default

- Page 785 and 786:

Table 15-4 Sequoyah Restart Input F

- Page 787 and 788:

compartment. The subsequent upward

- Page 789 and 790:

350 I I I I I I I i I I I i 325 300

- Page 791 and 792:

80 70 60 50 40 30 20 10 ? i I i / /

- Page 793 and 794:

combustion as calculated by the hyd

- Page 795 and 796:

16.1 Introduction 16.0 OUTPUT FILES

- Page 797 and 798:

will report conditions that might h

- Page 799 and 800:

To achieve this objective, POSTCON

- Page 801 and 802:

typically very undescriptive, a sho

- Page 803 and 804:

Table 16-1 Item Keywords (Continued

- Page 805 and 806:

Table 16-1 Item Keywords (Continued

- Page 807 and 808:

Table 16-1 Item Keywords (Continued

- Page 809 and 810:

Table 16-1 Item Keywords (Continued

- Page 811 and 812:

Table 16-2 Default Conversion Facto

- Page 813 and 814:

16.3.4.1 Simzle Pass. For simple pr

- Page 815 and 816:

16.4.1.3 Bin ary Plot File (PLTFIL)

- Page 817 and 818:

16.5 COntrol Block The general stru

- Page 819 and 820:

MAXSNI? keyword that initiates inpu

- Page 821 and 822:

EOI termination for the entire cont

- Page 823 and 824:

VECTOR ovname keyword that initiate

- Page 825 and 826:

EOF keyword thatterminates theendof

- Page 827 and 828:

POSTCON routine, and possibly writi

- Page 829 and 830:

Three units are converted in this e

- Page 831 and 832:

pltfil=plotl pout=poutl pvec=pvecl

- Page 833 and 834:

&& poet snapshot vector for flag: 5

- Page 835 and 836:

Figure 16-9. PMIX1 File from Exampl

- Page 837 and 838:

cell=2 vector=mettmp layer=3 type=t

- Page 839:

16.10.3 Output Handling When a user

- Page 842 and 843:

Ben84 Ber85a Ber85b Ber86 Bi193 Bin

- Page 844 and 845:

Dhi78 Din86 Dui89 Dun84 Edw73 E1w62

- Page 846 and 847:

Hin82 H068 H0168 Hot67 HUS88 Ide60

- Page 848 and 849:

Low82 Lui83 Lut91 Mak70 Mar86 Mas58

- Page 850 and 851:

Pi195 Pi196 Pit89 Pon90 POW86 POW93

- Page 852 and 853:

Sum95 Ta180 Tam85 Tarn87 Tam88 Tar8

- Page 854 and 855: was95 Wea85 Web92 Wei72 Wha78 Wi187

- Page 857 and 858: A. 1 Introduction APPENDIX A DETAIL

- Page 859 and 860: thermodynamic states. However, the

- Page 861 and 862: = h~(T) (for non-coolant liquids, s

- Page 863 and 864: (A-4) where N~X~j is the number of

- Page 865 and 866: .. in the liquid and vapor enthalpi

- Page 867 and 868: APPENDIX B 1 ALTERNATE INPUT FORMAT

- Page 869 and 870: .- AREA,i,j = area AVL,i,j = avl CF

- Page 871 and 872: n x PDAFLAG keyword discussed above

- Page 873 and 874: parameter string, the redefined val

- Page 875 and 876: RELEASE specifies nontargeted relea

- Page 877 and 878: nraycc number of rays used to model

- Page 879 and 880: ishape nslab ibc tint Chrl vufac bc

- Page 881 and 882: keywords FLAG, X, and Y are given i

- Page 883 and 884: C. 1 Introduction APPENDIX C VALIDA

- Page 885 and 886: Validation is considered outside th

- Page 887 and 888: 2) Medium = prediction of prime qua

- Page 889 and 890: C.3.4 Aerosol Behavior Table C-7 pr

- Page 891 and 892: product behavior, it can be used to

- Page 893 and 894: Table C-1 CONTAIN Code Release Hist

- Page 895 and 896: Table C-3 Validation Matrix for Atm

- Page 897 and 898: Table C-3 Validation Matrix for Atm

- Page 899 and 900: Table C-3 Validation Matrix for Atm

- Page 901 and 902: Table C-3 Validation Matrix for Atm

- Page 903: Table C-3 Validation Matrix for Atm

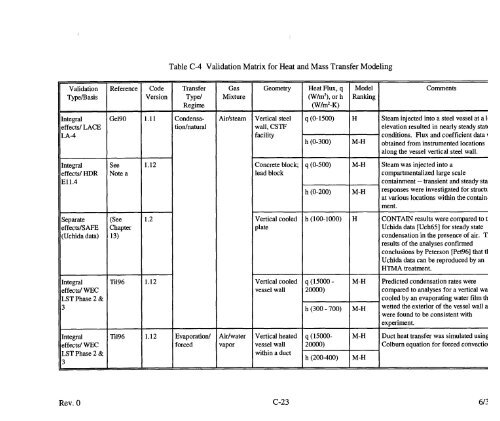

- Page 907 and 908: Table C-5 Validation Matrix for Hea

- Page 909 and 910: I Validation Type/Basis Separate ef

- Page 911 and 912: Table C-6 Validation Matrix for DCH

- Page 913 and 914: Table C-6 Validation Matrix for DCH

- Page 915 and 916: Experiment (Test Facility) SNLJIET-

- Page 917 and 918: (Footnotes for Table C-6 Continued)

- Page 919 and 920: Table C-7 Validation Matrix for Aer

- Page 921 and 922: Table C-8 Validation Matrix for Hyd

- Page 923 and 924: Table C-10 Validation Matrix for Mi

- Page 925 and 926: n 400 ) 300 % $ 200 ~ * o 6 100 * z

- Page 927 and 928: ~ ~ 0.10 0.08 g 0.06 a fn g n g 0.0

- Page 929 and 930: g 403 393 383 373 363 353 343 333 3

- Page 931 and 932: Has96b Hei86 Huh93 Jac89 Jon87 Jon8

- Page 933 and 934: Mur83b Mur88 Mur89 Mur96 0wc85 Pet9

- Page 935 and 936: Ti191 Ti196 Uch65 Va183 va188 Ver87

- Page 937 and 938: D. 1 Introduction APPENDIX D QUALIT

- Page 939 and 940: L==I-----F -—— - L I I I Desk M

- Page 941 and 942: Ir Lo! (o) Releases \ II T ata chan

- Page 943 and 944: the difilculty, resolving the issue

- Page 945 and 946: When the review is complete, the up

- Page 947 and 948: ● ensures that modifications will

- Page 949 and 950: -. . ---ula GMF Program Library \ O

- Page 951 and 952: instruction set that creates the va

- Page 953 and 954: experimental results. The objective

- Page 955 and 956:

D.2.6.4 Test Doc umentation. In eve

- Page 957 and 958:

REFERENCES Bi194 S. C. Billups et a

- Page 960:

4 QPrinted on recycled paper Federa