Catalog ST PCS 7.1 - September 2005

Catalog ST PCS 7.1 - September 2005

Catalog ST PCS 7.1 - September 2005

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

3<br />

Advanced Process Control<br />

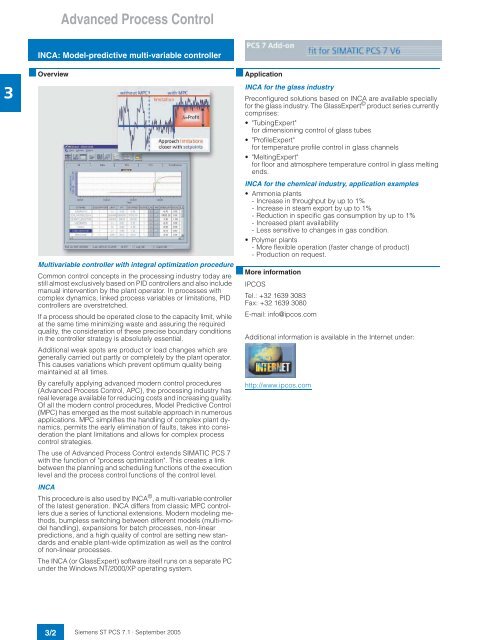

INCA: Model-predictive multi-variable controller<br />

■ Overview<br />

Multivariable controller with integral optimization procedure<br />

■ More information<br />

Common control concepts in the processing industry today are<br />

still almost exclusively based on PID controllers and also include IPCOS<br />

manual intervention by the plant operator. In processes with<br />

complex dynamics, linked process variables or limitations, PID Tel.: +32 1639 3083<br />

controllers are overstretched.<br />

Fax: +32 1639 3080<br />

If a process should be operated close to the capacity limit, while E-mail: info@ipcos.com<br />

at the same time minimizing waste and assuring the required<br />

quality, the consideration of these precise boundary conditions<br />

in the controller strategy is absolutely essential.<br />

Additional information is available in the Internet under:<br />

Additional weak spots are product or load changes which are<br />

generally carried out partly or completely by the plant operator.<br />

This causes variations which prevent optimum quality being<br />

maintained at all times.<br />

By carefully applying advanced modern control procedures http://www.ipcos.com<br />

(Advanced Process Control, APC), the processing industry has<br />

real leverage available for reducing costs and increasing quality.<br />

Of all the modern control procedures, Model Predictive Control<br />

(MPC) has emerged as the most suitable approach in numerous<br />

applications. MPC simplifies the handling of complex plant dynamics,<br />

permits the early elimination of faults, takes into consideration<br />

the plant limitations and allows for complex process<br />

control strategies.<br />

The use of Advanced Process Control extends SIMATIC <strong>PCS</strong> 7<br />

with the function of "process optimization". This creates a link<br />

between the planning and scheduling functions of the execution<br />

level and the process control functions of the control level.<br />

INCA<br />

This procedure is also used by INCA © , a multi-variable controller<br />

of the latest generation. INCA differs from classic MPC controllers<br />

due a series of functional extensions. Modern modeling methods,<br />

bumpless switching between different models (multi-model<br />

handling), expansions for batch processes, non-linear<br />

predictions, and a high quality of control are setting new standards<br />

and enable plant-wide optimization as well as the control<br />

of non-linear processes.<br />

The INCA (or GlassExpert) software itself runs on a separate PC<br />

under the Windows NT/2000/XP operating system.<br />

3/2<br />

Siemens <strong>ST</strong> <strong>PCS</strong> <strong>7.1</strong> · <strong>September</strong> <strong>2005</strong><br />

■ Application<br />

INCA for the glass industry<br />

Preconfigured solutions based on INCA are available specially<br />

for the glass industry. The GlassExpert © product series currently<br />

comprises:<br />

• "TubingExpert"<br />

for dimensioning control of glass tubes<br />

• "ProfileExpert"<br />

for temperature profile control in glass channels<br />

• "MeltingExpert"<br />

for floor and atmosphere temperature control in glass melting<br />

ends.<br />

INCA for the chemical industry, application examples<br />

• Ammonia plants<br />

- Increase in throughput by up to 1%<br />

- Increase in steam export by up to 1%<br />

- Reduction in specific gas consumption by up to 1%<br />

- Increased plant availability<br />

- Less sensitive to changes in gas condition.<br />

• Polymer plants<br />

- More flexible operation (faster change of product)<br />

- Production on request.