Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

452<br />

<strong>of</strong> measuring wheels so that abetter reference line can be used. However, this <strong>of</strong>fsets the essential<br />

benefit <strong>of</strong> this method, namely its simplicity.<br />

Chord <strong>of</strong>fset based measuring vehicles are no longer incommon usage and data measured by<br />

such systems should betreated with some caution by the dynamics engineer for the reasons<br />

discussed.<br />

VII. EXAMPLES OF VEHICLE LABORATORY AND FIELD TESTS<br />

This sectionprovide examples <strong>of</strong> laboratory andfieldtests that maybecommonlyencountered by,or<br />

provide useful information for, the vehicle dynamics engineer. Whilst they are based specifically on<br />

U.K. practice, similar tests are employed bymany railway administrations worldwide.<br />

A. S TATIC/QUASI- S TATIC T ESTS<br />

These tests are normally carriedout on avehicle in aspecialist laboratory. Theresults may be used<br />

to gain confidence in the general behaviour <strong>of</strong> avehicle model and also to estimate the additional<br />

(parasitic) stiffness present in the completed vehicle. However, as the dynamic behaviour can vary<br />

considerably from the static behaviour, some comparisons against dynamics tests (such as ride<br />

tests) are required toenable avehicle model to be fully validated.<br />

1. Wheel Unloading Test<br />

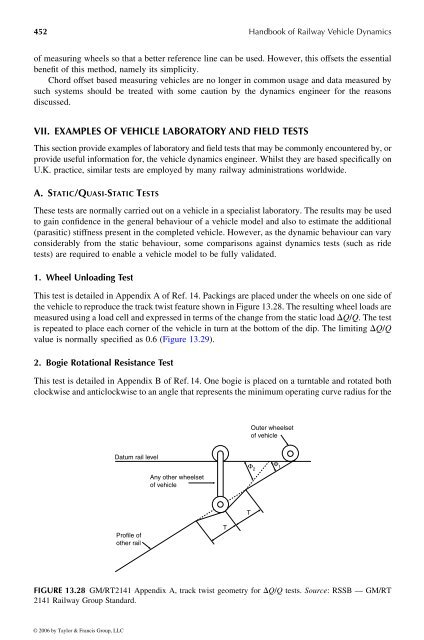

This testisdetailed in Appendix A<strong>of</strong>Ref. 14.Packings are placed under the wheels on one side <strong>of</strong><br />

the vehicle to reproduce the track twist featureshown in Figure 13.28.The resulting wheel loads are<br />

measured usingaload cell and expressedinterms <strong>of</strong> the change from the static load D Q / Q .The test<br />

is repeated to place each corner <strong>of</strong>the vehicle in turn at the bottom <strong>of</strong> the dip. The limiting D Q / Q<br />

value isnormally specified as 0.6 (Figure 13.29).<br />

2. Bogie Rotational Resistance Test<br />

This test is detailed in Appendix B<strong>of</strong>Ref. 14. One bogie is placed on aturntable and rotated both<br />

clockwise and anticlockwise to an anglethat represents the minimum operating curve radius for the<br />

Datum rail level<br />

Pr<strong>of</strong>ile <strong>of</strong><br />

other rail<br />

Any other wheelset<br />

<strong>of</strong> vehicle<br />

Outer wheelset<br />

<strong>of</strong> vehicle<br />

FIGURE 13.28 GM/RT2141 Appendix A, track twist geometry for D Q / Q tests. Source: RSSB —GM/RT<br />

2141 <strong>Railway</strong> Group Standard.<br />

© 2006 by Taylor & Francis Group, LLC<br />

T<br />

Φ 2<br />

T<br />

<strong>Handbook</strong> <strong>of</strong> <strong>Railway</strong> <strong>Vehicle</strong> <strong>Dynamics</strong><br />

Φ 1