HAHN+KOLB-Toolcatalog 2011/12 – Testing equipment

HAHN+KOLB-Toolcatalog 2011/12 – Testing equipment

HAHN+KOLB-Toolcatalog 2011/12 – Testing equipment

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Hardness testing and metallography<br />

Stationary hardness testers<br />

Continued next page<br />

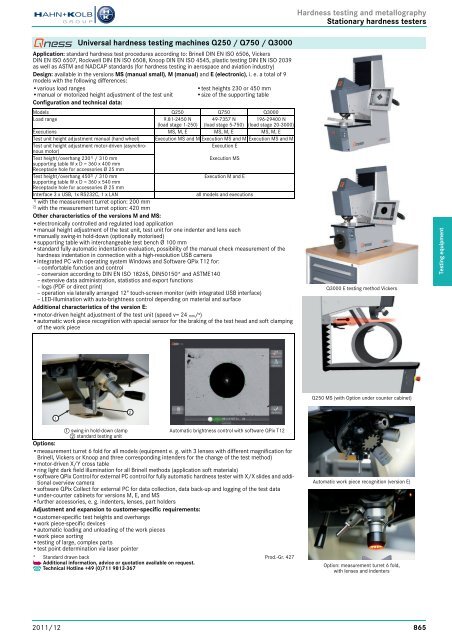

Universal hardness testing machines Q250 / Q750 / Q3000<br />

Application: standard hardness test procedures according to: Brinell DIN EN ISO 6506, Vickers<br />

DIN EN ISO 6507, RockweIl DIN EN ISO 6508, Knoop DIN EN ISO 4545, plastic testing DIN EN ISO 2039<br />

as well as ASTM and NADCAP standards (for hardness testing in aerospace and aviation industry)<br />

Design: available in the versions MS (manual small), M (manual) and E (electronic), i. e. a total of 9<br />

models with the following differences:<br />

•various load ranges<br />

•manual or motorized height adjustment of the test unit<br />

•test heights 230 or 450 mm<br />

•size of the supporting table<br />

Configuration and technical data:<br />

Models Q250 Q750 Q3000<br />

Load range<br />

9.81-2450 N 49-7357 N 196-29400 N<br />

(load stage 1-250) (load stage 5-750) (load stage 20-3000)<br />

Executions MS, M, E MS, M, E MS, M, E<br />

Test unit height adjustment manual (hand wheel) Execution MS and M Execution MS and M Execution MS and M<br />

Test unit height adjustment motor-driven (asynchronous<br />

motor)<br />

Execution E<br />

Test height/overhang 230 1) / 310 mm<br />

Execution MS<br />

supporting table W x D = 360 x 400 mm<br />

Receptacle hole for accessories Ø 25 mm<br />

Test height/overhang 450 2) / 310 mm<br />

Execution M and E<br />

supporting table W x D = 360 x 540 mm<br />

Receptacle hole for accessories Ø 25 mm<br />

Interface 3 x USB, 1x RS232C, 1 x LAN<br />

all models and executions<br />

1)<br />

with the measurement turret option: 200 mm<br />

2)<br />

with the measurement turret option: 420 mm<br />

Other characteristics of the versions M and MS:<br />

•electronically controlled and regulated load application<br />

•manual height adjustment of the test unit, test unit for one indenter and lens each<br />

•manually swing-in hold-down (optionally motorised)<br />

•supporting table with interchangeable test bench Ø 100 mm<br />

•standard fully automatic indentation evaluation, possibility of the manual check measurement of the<br />

hardness indentation in connection with a high-resolution USB camera<br />

•integrated PC with operating system Windows and Software QPix T<strong>12</strong> for:<br />

<strong>–</strong> comfortable function and control<br />

<strong>–</strong> conversion according to DIN EN ISO 18265, DIN50150* and ASTME140<br />

<strong>–</strong> extensive data administration, statistics and export functions<br />

<strong>–</strong> logs (PDF or direct print)<br />

<strong>–</strong> operation via laterally arranged <strong>12</strong>" touch-screen monitor (with integrated USB interface)<br />

<strong>–</strong> LED-illumination with auto-brightness control depending on material and surface<br />

Additional characteristics of the version E:<br />

•motor-driven height adjustment of the test unit (speed v= 24 mm/ s )<br />

•automatic work piece recognition with special sensor for the braking of the test head and soft clamping<br />

of the work piece<br />

Q3000 E testing method Vickers<br />

<strong>Testing</strong> <strong>equipment</strong><br />

Q250 MS (with Option under counter cabinet)<br />

1<br />

2<br />

1 swing-in hold-down clamp<br />

Automatic brightness control with software QPix T<strong>12</strong><br />

2 standard testing unit<br />

Options:<br />

•measurement turret 6 fold for all models (<strong>equipment</strong> e. g. with 3 lenses with different magnification for<br />

Brinell, Vickers or Knoop and three corresponding intenders for the change of the test method)<br />

•motor-driven X/Y cross table<br />

•ring light dark field illumination for all Brinell methods (application soft materials)<br />

•software QPix Control for external PC control for fully automatic hardness tester with X/X slides and additional<br />

overview camera<br />

•software QPix Collect for external PC for data collection, data back-up and logging of the test data<br />

•under-counter cabinets for versions M, E, and MS<br />

•further accessories, e. g. indenters, lenses, part holders<br />

Adjustment and expansion to customer-specific requirements:<br />

•customer-specific test heights and overhangs<br />

•work piece-specific devices<br />

•automatic loading and unloading of the work pieces<br />

•work piece sorting<br />

•testing of large, complex parts<br />

•test point determination via laser pointer<br />

* Standard drawn back<br />

Prod.-Gr. 427<br />

h Additional information, advice or quotation available on request.<br />

t Technical Hotline +49 (0)711 9813-367<br />

Automatic work piece recognition (version E)<br />

Option: measurement turret 6 fold,<br />

with lenses and indenters<br />

<strong>2011</strong>/<strong>12</strong><br />

865