HAHN+KOLB-Toolcatalog 2011/12 – Testing equipment

HAHN+KOLB-Toolcatalog 2011/12 – Testing equipment

HAHN+KOLB-Toolcatalog 2011/12 – Testing equipment

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Contour and roughness measurements<br />

Surface-roughness reference samples<br />

Continued next page<br />

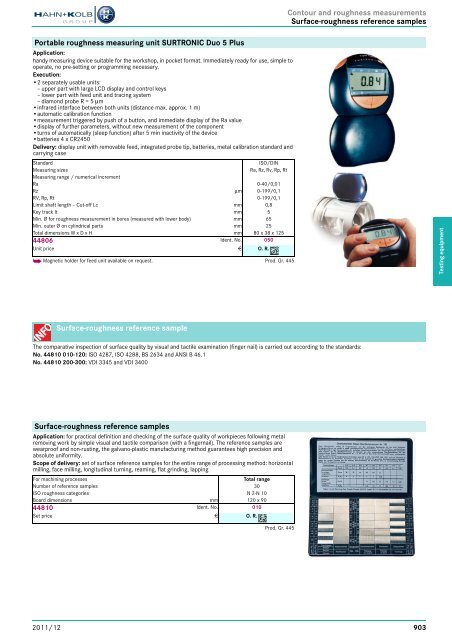

Portable roughness measuring unit SURTRONIC Duo 5 Plus<br />

Application:<br />

handy measuring device suitable for the workshop, in pocket format. Immediately ready for use, simple to<br />

operate, no pre-setting or programming necessary.<br />

Execution:<br />

•2 separately usable units:<br />

<strong>–</strong> upper part with large LCD display and control keys<br />

<strong>–</strong> lower part with feed unit and tracing system<br />

<strong>–</strong> diamond probe R = 5 μm<br />

•infrared interface between both units (distance max. approx. 1 m)<br />

•automatic calibration function<br />

•measurement triggered by push of a button, and immediate display of the Ra value<br />

•display of further parameters, without new measurement of the component<br />

•turns of automatically (sleep function) after 5 min inactivity of the device<br />

•batteries 4 x CR2450<br />

Delivery: display unit with removable feed, integrated probe tip, batteries, metal calibration standard and<br />

carrying case<br />

Standard<br />

ISO/DIN<br />

Measuring sizes<br />

Ra, Rz, Rv, Rp, Rt<br />

Measuring range / numerical increment<br />

Ra 0-40/0,01<br />

Rz μm 0-199/0,1<br />

RV, Rp, Rt 0-199/0,1<br />

Limit shaft length <strong>–</strong> Cut-off Lc mm 0,8<br />

Key track lt mm 5<br />

Min. Ø for roughness measurement in bores (measured with lower body) mm 65<br />

Min. outer Ø on cylindrical parts mm 25<br />

Total dimensions W x D x H mm 80 x 38 x <strong>12</strong>5<br />

44806 Ident. No. 050<br />

Unit price E O. R.<br />

h Magnetic holder for feed unit available on request. Prod. Gr. 445<br />

<strong>Testing</strong> <strong>equipment</strong><br />

Continued next page<br />

Surface-roughness reference sample<br />

The comparative inspection of surface quality by visual and tactile examination (finger nail) is carried out according to the standards:<br />

No. 44810 010-<strong>12</strong>0: ISO 4287, ISO 4288, BS 2634 and ANSI B 46.1<br />

No. 44810 200-300: VDI 3345 and VDI 3400<br />

Continued next page<br />

Surface-roughness reference samples<br />

Application: for practical definition and checking of the surface quality of workpieces following metal<br />

removing work by simple visual and tactile comparison (with a fingernail). The reference samples are<br />

wearproof and non-rusting, the galvano-plastic manufacturing method guarantees high precision and<br />

absolute uniformity.<br />

Scope of delivery: set of surface reference samples for the entire range of processing method: horizontal<br />

milling, face milling, longitudinal turning, reaming, flat grinding, lapping<br />

For machining processes<br />

Total range<br />

Number of reference samples 30<br />

ISO roughness categories N 2-N 10<br />

Board dimensions mm <strong>12</strong>0 x 90<br />

44810 Ident. No. 010<br />

Set price E O. R.<br />

Prod. Gr. 445<br />

<strong>2011</strong>/<strong>12</strong><br />

903