Strona 2_redak - Instytut Agrofizyki im. Bohdana DobrzaÅskiego ...

Strona 2_redak - Instytut Agrofizyki im. Bohdana DobrzaÅskiego ...

Strona 2_redak - Instytut Agrofizyki im. Bohdana DobrzaÅskiego ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

18<br />

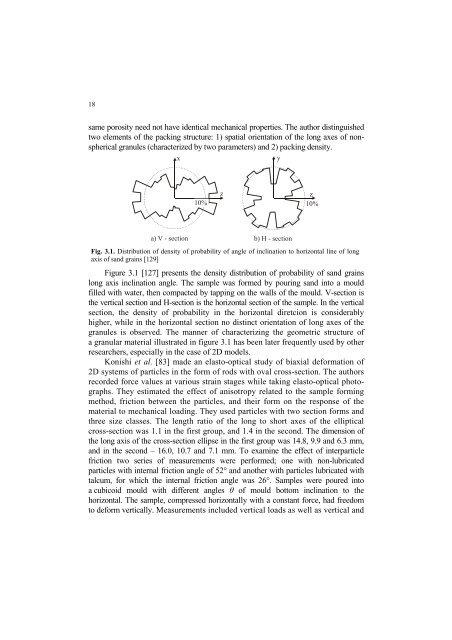

same porosity need not have identical mechanical properties. The author distinguished<br />

two elements of the packing structure: 1) spatial orientation of the long axes of nonspherical<br />

granules (characterized by two parameters) and 2) packing density.<br />

x<br />

y<br />

z<br />

z<br />

10%<br />

10%<br />

a) V - section b) H - section<br />

Fig. 3.1. Distribution of density of probability of angle of inclination to horizontal line of long<br />

axis of sand grains [129]<br />

Figure 3.1 [127] presents the density distribution of probability of sand grains<br />

long axis inclination angle. The sample was formed by pouring sand into a mould<br />

filled with water, then compacted by tapping on the walls of the mould. V-section is<br />

the vertical section and H-section is the horizontal section of the sample. In the vertical<br />

section, the density of probability in the horizontal diretcion is considerably<br />

higher, while in the horizontal section no distinct orientation of long axes of the<br />

granules is observed. The manner of characterizing the geometric structure of<br />

a granular material illustrated in figure 3.1 has been later frequently used by other<br />

researchers, especially in the case of 2D models.<br />

Konishi et al. [83] made an elasto-optical study of biaxial deformation of<br />

2D systems of particles in the form of rods with oval cross-section. The authors<br />

recorded force values at various strain stages while taking elasto-optical photographs.<br />

They est<strong>im</strong>ated the effect of anisotropy related to the sample forming<br />

method, friction between the particles, and their form on the response of the<br />

material to mechanical loading. They used particles with two section forms and<br />

three size classes. The length ratio of the long to short axes of the elliptical<br />

cross-section was 1.1 in the first group, and 1.4 in the second. The d<strong>im</strong>ension of<br />

the long axis of the cross-section ellipse in the first group was 14.8, 9.9 and 6.3 mm,<br />

and in the second – 16.0, 10.7 and 7.1 mm. To examine the effect of interparticle<br />

friction two series of measurements were performed; one with non-lubricated<br />

particles with internal friction angle of 52° and another with particles lubricated with<br />

talcum, for which the internal friction angle was 26°. Samples were poured into<br />

a cubicoid mould with different angles θ of mould bottom inclination to the<br />

horizontal. The sample, compressed horizontally with a constant force, had freedom<br />

to deform vertically. Measurements included vertical loads as well as vertical and