Strona 2_redak - Instytut Agrofizyki im. Bohdana DobrzaÅskiego ...

Strona 2_redak - Instytut Agrofizyki im. Bohdana DobrzaÅskiego ...

Strona 2_redak - Instytut Agrofizyki im. Bohdana DobrzaÅskiego ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

96<br />

The Chute Index (CI) is recommended chute angle to el<strong>im</strong>inate solids build up on<br />

a chute at <strong>im</strong>pact points. The index takes value of CI = ASC +10°, where ASC is an angle<br />

of slipping friction along the flat surface of the bulk solid sample compressed with the<br />

pressure of 4700 N m -2 and unloaded prior to determination of ASC.<br />

The Springback Index (SBI) is the percentage of elastic springback after consolidation,<br />

and indicates when springy solids (as straw, wood, polymer foam) may<br />

arch. SBI is measured by compressing the solid to a pressure of D×BDI , and then<br />

noting the percentage change in the sample height when the load is released.<br />

Knowledge of material characteristics expressed as values of indices allows<br />

for design of technological process as anticipated. Johanson [78] presented an<br />

example of use of the indices in design of the process of blending without segregation<br />

of components.<br />

3.1.3. Jenike & Johanson powder quality tester<br />

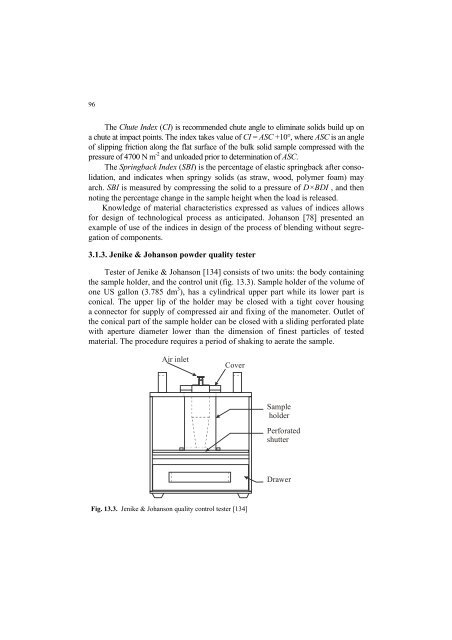

Tester of Jenike & Johanson [134] consists of two units: the body containing<br />

the sample holder, and the control unit (fig. 13.3). Sample holder of the volume of<br />

one US gallon (3.785 dm 3 ), has a cylindrical upper part while its lower part is<br />

conical. The upper lip of the holder may be closed with a tight cover housing<br />

a connector for supply of compressed air and fixing of the manometer. Outlet of<br />

the conical part of the sample holder can be closed with a sliding perforated plate<br />

with aperture diameter lower than the d<strong>im</strong>ension of finest particles of tested<br />

material. The procedure requires a period of shaking to aerate the sample.<br />

$LULQOHW<br />

&RYHU<br />

6DPSOH<br />

KROGHU<br />

3HUIRUDWHG<br />

VKXWWHU<br />

'UDZHU<br />

Fig. 13.3. Jenike & Johanson quality control tester [134]