Strona 2_redak - Instytut Agrofizyki im. Bohdana DobrzaÅskiego ...

Strona 2_redak - Instytut Agrofizyki im. Bohdana DobrzaÅskiego ...

Strona 2_redak - Instytut Agrofizyki im. Bohdana DobrzaÅskiego ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

69<br />

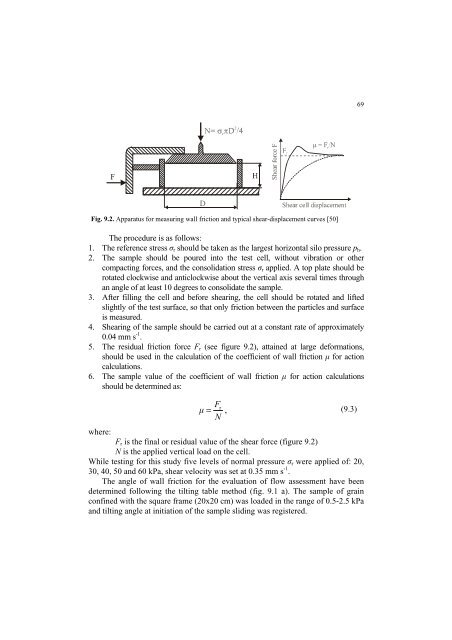

Fig. 9.2. Apparatus for measuring wall friction and typical shear-displacement curves [50]<br />

The procedure is as follows:<br />

1. The reference stress 1 r should be taken as the largest horizontal silo pressure p h .<br />

2. The sample should be poured into the test cell, without vibration or other<br />

compacting forces, and the consolidation stress 1 r applied. A top plate should be<br />

rotated clockwise and anticlockwise about the vertical axis several t<strong>im</strong>es through<br />

an angle of at least 10 degrees to consolidate the sample.<br />

3. After filling the cell and before shearing, the cell should be rotated and lifted<br />

slightly of the test surface, so that only friction between the particles and surface<br />

is measured.<br />

4. Shearing of the sample should be carried out at a constant rate of approx<strong>im</strong>ately<br />

0.04 mm s -1 .<br />

5. The residual friction force F r (see figure 9.2), attained at large deformations,<br />

should be used in the calculation of the coefficient of wall friction for action<br />

calculations.<br />

6. The sample value of the coefficient of wall friction for action calculations<br />

should be determined as:<br />

Fr<br />

= , (9.3)<br />

N<br />

where:<br />

F r is the final or residual value of the shear force (figure 9.2)<br />

N is the applied vertical load on the cell.<br />

While testing for this study five levels of normal pressure 1 r were applied of: 20,<br />

30, 40, 50 and 60 kPa, shear velocity was set at 0.35 mm s -1 .<br />

The angle of wall friction for the evaluation of flow assessment have been<br />

determined following the tilting table method (fig. 9.1 a). The sample of grain<br />

confined with the square frame (20x20 cm) was loaded in the range of 0.5-2.5 kPa<br />

and tilting angle at initiation of the sample sliding was registered.