Strona 2_redak - Instytut Agrofizyki im. Bohdana DobrzaÅskiego ...

Strona 2_redak - Instytut Agrofizyki im. Bohdana DobrzaÅskiego ...

Strona 2_redak - Instytut Agrofizyki im. Bohdana DobrzaÅskiego ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

84<br />

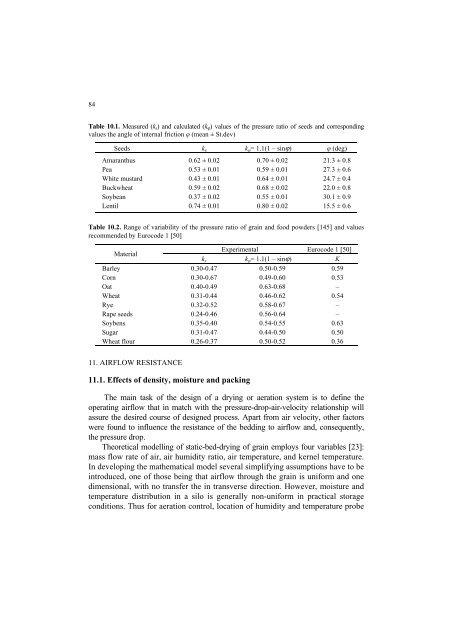

Table 10.1. Measured (k s ) and calculated (k ϕ ) values of the pressure ratio of seeds and corresponding<br />

values the angle of internal friction 3 (mean ± St.dev)<br />

Seeds k s k 3 = 1.1(1 – sinϕ) 3 (deg)<br />

Amaranthus<br />

Pea<br />

White mustard<br />

Buckwheat<br />

Soybean<br />

Lentil<br />

0.62 ± 0.02<br />

0.53 ± 0.01<br />

0.43 ± 0.01<br />

0.59 ± 0.02<br />

0.37 ± 0.02<br />

0.74 ± 0.01<br />

0.70 ± 0.02<br />

0.59 ± 0.01<br />

0.64 ± 0.01<br />

0.68 ± 0.02<br />

0.55 ± 0.01<br />

0.80 ± 0.02<br />

21.3 ± 0.8<br />

27.3 ± 0.6<br />

24.7 ± 0.4<br />

22.0 ± 0.8<br />

30.1 ± 0.9<br />

15.5 ± 0.6<br />

Table 10.2. Range of variability of the pressure ratio of grain and food powders [145] and values<br />

recommended by Eurocode 1 [50]<br />

Material<br />

Barley<br />

Corn<br />

Oat<br />

Wheat<br />

Rye<br />

Rape seeds<br />

Soybens<br />

Sugar<br />

Wheat flour<br />

Exper<strong>im</strong>ental Eurocode 1 [50]<br />

k s k 3 = 1.1(1 – sinϕ) K<br />

0.30-0.47<br />

0.30-0.67<br />

0.40-0.49<br />

0.31-0.44<br />

0.32-0.52<br />

0.24-0.46<br />

0.35-0.40<br />

0.31-0.47<br />

0.26-0.37<br />

0.50-0.59<br />

0.49-0.60<br />

0.63-0.68<br />

0.46-0.62<br />

0.58-0.67<br />

0.56-0.64<br />

0.54-0.55<br />

0.44-0.50<br />

0.50-0.52<br />

0.59<br />

0.53<br />

–<br />

0.54<br />

–<br />

–<br />

0.63<br />

0.50<br />

0.36<br />

11. AIRFLOW RESISTANCE<br />

11.1. Effects of density, moisture and packing<br />

The main task of the design of a drying or aeration system is to define the<br />

operating airflow that in match with the pressure-drop-air-velocity relationship will<br />

assure the desired course of designed process. Apart from air velocity, other factors<br />

were found to influence the resistance of the bedding to airflow and, consequently,<br />

the pressure drop.<br />

Theoretical modelling of static-bed-drying of grain employs four variables [23]:<br />

mass flow rate of air, air humidity ratio, air temperature, and kernel temperature.<br />

In developing the mathematical model several s<strong>im</strong>plifying assumptions have to be<br />

introduced, one of those being that airflow through the grain is uniform and one<br />

d<strong>im</strong>ensional, with no transfer the in transverse direction. However, moisture and<br />

temperature distribution in a silo is generally non-uniform in practical storage<br />

conditions. Thus for aeration control, location of humidity and temperature probe