Strona 2_redak - Instytut Agrofizyki im. Bohdana DobrzaÅskiego ...

Strona 2_redak - Instytut Agrofizyki im. Bohdana DobrzaÅskiego ...

Strona 2_redak - Instytut Agrofizyki im. Bohdana DobrzaÅskiego ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

51<br />

N=σ r<br />

πD 2<br />

4<br />

T = τ πD 2<br />

4<br />

ro u g h<br />

H<br />

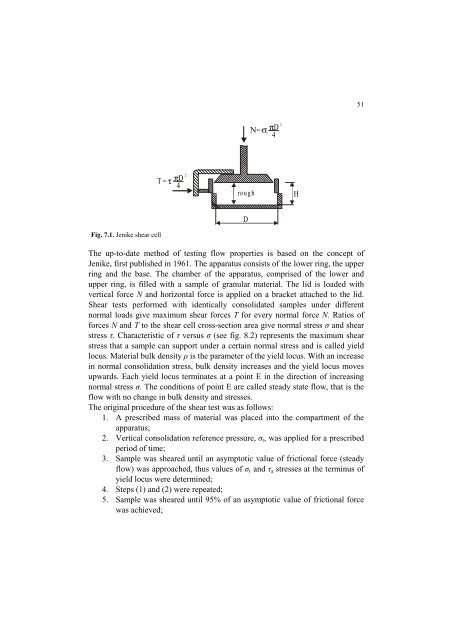

Fig. 7.1. Jenike shear cell<br />

D<br />

The up-to-date method of testing flow properties is based on the concept of<br />

Jenike, first published in 1961. The apparatus consists of the lower ring, the upper<br />

ring and the base. The chamber of the apparatus, comprised of the lower and<br />

upper ring, is filled with a sample of granular material. The lid is loaded with<br />

vertical force N and horizontal force is applied on a bracket attached to the lid.<br />

Shear tests performed with identically consolidated samples under different<br />

normal loads give max<strong>im</strong>um shear forces T for every normal force N. Ratios of<br />

forces N and T to the shear cell cross-section area give normal stress σ and shear<br />

stress τ. Characteristic of τ versus σ (see fig. 8.2) represents the max<strong>im</strong>um shear<br />

stress that a sample can support under a certain normal stress and is called yield<br />

locus. Material bulk density ρ is the parameter of the yield locus. With an increase<br />

in normal consolidation stress, bulk density increases and the yield locus moves<br />

upwards. Each yield locus terminates at a point E in the direction of increasing<br />

normal stress σ. The conditions of point E are called steady state flow, that is the<br />

flow with no change in bulk density and stresses.<br />

The original procedure of the shear test was as follows:<br />

1. A prescribed mass of material was placed into the compartment of the<br />

apparatus;<br />

2. Vertical consolidation reference pressure, σ r , was applied for a prescribed<br />

period of t<strong>im</strong>e;<br />

3. Sample was sheared until an asymptotic value of frictional force (steady<br />

flow) was approached, thus values of σ r and τ a stresses at the terminus of<br />

yield locus were determined;<br />

4. Steps (1) and (2) were repeated;<br />

5. Sample was sheared until 95% of an asymptotic value of frictional force<br />

was achieved;