Strona 2_redak - Instytut Agrofizyki im. Bohdana DobrzaÅskiego ...

Strona 2_redak - Instytut Agrofizyki im. Bohdana DobrzaÅskiego ...

Strona 2_redak - Instytut Agrofizyki im. Bohdana DobrzaÅskiego ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

72<br />

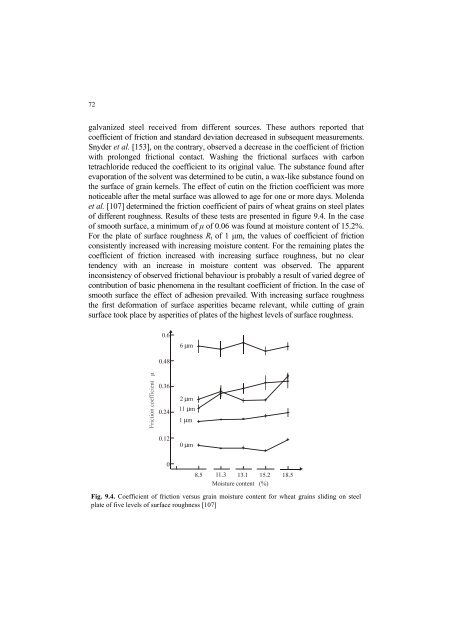

galvanized steel received from different sources. These authors reported that<br />

coefficient of friction and standard deviation decreased in subsequent measurements.<br />

Snyder et al. [153], on the contrary, observed a decrease in the coefficient of friction<br />

with prolonged frictional contact. Washing the frictional surfaces with carbon<br />

tetrachloride reduced the coefficient to its original value. The substance found after<br />

evaporation of the solvent was determined to be cutin, a wax-like substance found on<br />

the surface of grain kernels. The effect of cutin on the friction coefficient was more<br />

noticeable after the metal surface was allowed to age for one or more days. Molenda<br />

et al. [107] determined the friction coefficient of pairs of wheat grains on steel plates<br />

of different roughness. Results of these tests are presented in figure 9.4. In the case<br />

of smooth surface, a min<strong>im</strong>um of of 0.06 was found at moisture content of 15.2%.<br />

For the plate of surface roughness R t RI P WKH YDOXHVRI FRHIILFLHQW RI IULFWLRQ<br />

consistently increased with increasing moisture content. For the remaining plates the<br />

coefficient of friction increased with increasing surface roughness, but no clear<br />

tendency with an increase in moisture content was observed. The apparent<br />

inconsistency of observed frictional behaviour is probably a result of varied degree of<br />

contribution of basic phenomena in the resultant coefficient of friction. In the case of<br />

smooth surface the effect of adhesion prevailed. With increasing surface roughness<br />

the first deformation of surface asperities became relevant, while cutting of grain<br />

surface took place by asperities of plates of the highest levels of surface roughness.<br />

<br />

µ<br />

P<br />

<br />

<br />

<br />

µ<br />

P<br />

µ<br />

P<br />

µ<br />

P<br />

<br />

µ<br />

P<br />

<br />

<br />

0RLVWXUHFRQWHQW<br />

Fig. 9.4. Coefficient of friction versus grain moisture content for wheat grains sliding on steel<br />

plate of five levels of surface roughness [107]