Strona 2_redak - Instytut Agrofizyki im. Bohdana DobrzaÅskiego ...

Strona 2_redak - Instytut Agrofizyki im. Bohdana DobrzaÅskiego ...

Strona 2_redak - Instytut Agrofizyki im. Bohdana DobrzaÅskiego ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

63<br />

8. FLOW FUNCTION<br />

In the early 1960s the angle of repose was used as an index of flowability of<br />

granular material. In 1961 [74] Jenike published his best known work in which he<br />

proposed direct shear test for est<strong>im</strong>ation of flowability, while his analytical method<br />

provided a physical interpretation of test results. After Jenike’s recommendation,<br />

shear testing to determine the flow function has been widely accepted by researchers<br />

and practitioners and still remains in use. The concept of flow function may be<br />

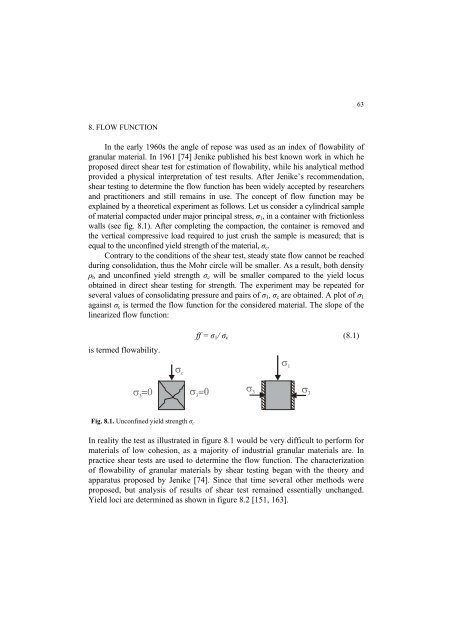

explained by a theoretical exper<strong>im</strong>ent as follows. Let us consider a cylindrical sample<br />

of material compacted under major principal stress, 1 1 , in a container with frictionless<br />

walls (see fig. 8.1). After completing the compaction, the container is removed and<br />

the vertical compressive load required to just crush the sample is measured; that is<br />

equal to the unconfined yield strength of the material, 1 c .<br />

Contrary to the conditions of the shear test, steady state flow cannot be reached<br />

during consolidation, thus the Mohr circle will be smaller. As a result, both density<br />

! b and unconfined yield strength 1 c will be smaller compared to the yield locus<br />

obtained in direct shear testing for strength. The exper<strong>im</strong>ent may be repeated for<br />

several values of consolidating pressure and pairs of 1 1 1 c are obtained. A plot of 1 1<br />

against 1 c is termed the flow function for the considered material. The slope of the<br />

linearized flow function:<br />

is termed flowability.<br />

II 1 1 1 c (8.1)<br />

Fig. 8.1. Unconfined yield strength 1 c<br />

In reality the test as illustrated in figure 8.1 would be very difficult to perform for<br />

materials of low cohesion, as a majority of industrial granular materials are. In<br />

practice shear tests are used to determine the flow function. The characterization<br />

of flowability of granular materials by shear testing began with the theory and<br />

apparatus proposed by Jenike [74]. Since that t<strong>im</strong>e several other methods were<br />

proposed, but analysis of results of shear test remained essentially unchanged.<br />

Yield loci are determined as shown in figure 8.2 [151, 163].