Part III: Flare Reduction Project Family - IPIECA

Part III: Flare Reduction Project Family - IPIECA

Part III: Flare Reduction Project Family - IPIECA

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

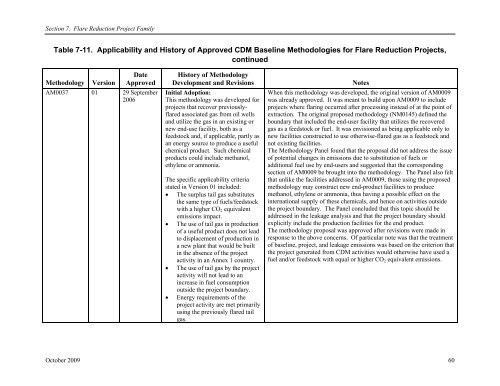

Section 7. <strong>Flare</strong> <strong>Reduction</strong> <strong>Project</strong> <strong>Family</strong><br />

Table 7-11. Applicability and History of Approved CDM Baseline Methodologies for <strong>Flare</strong> <strong>Reduction</strong> <strong>Project</strong>s,<br />

continued<br />

Methodology Version<br />

Date<br />

Approved<br />

AM0037 01 29 September<br />

2006<br />

History of Methodology<br />

Development and Revisions<br />

Initial Adoption:<br />

This methodology was developed for<br />

projects that recover previouslyflared<br />

associated gas from oil wells<br />

and utilize the gas in an existing or<br />

new end-use facility, both as a<br />

feedstock and, if applicable, partly as<br />

an energy source to produce a useful<br />

chemical product. Such chemical<br />

products could include methanol,<br />

ethylene or ammonia.<br />

The specific applicability criteria<br />

stated in Version 01 included:<br />

• The surplus tail gas substitutes<br />

the same type of fuels/feedstock<br />

with a higher CO 2 equivalent<br />

emissions impact.<br />

• The use of tail gas in production<br />

of a useful product does not lead<br />

to displacement of production in<br />

a new plant that would be built<br />

in the absence of the project<br />

activity in an Annex 1 country.<br />

• The use of tail gas by the project<br />

activity will not lead to an<br />

increase in fuel consumption<br />

outside the project boundary.<br />

• Energy requirements of the<br />

project activity are met primarily<br />

using the previously flared tail<br />

gas.<br />

Notes<br />

When this methodology was developed, the original version of AM0009<br />

was already approved. It was meant to build upon AM0009 to include<br />

projects where flaring occurred after processing instead of at the point of<br />

extraction. The original proposed methodology (NM0145) defined the<br />

boundary that included the end-user facility that utilizes the recovered<br />

gas as a feedstock or fuel. It was envisioned as being applicable only to<br />

new facilities constructed to use otherwise-flared gas as a feedstock and<br />

not existing facilities.<br />

The Methodology Panel found that the proposal did not address the issue<br />

of potential changes in emissions due to substitution of fuels or<br />

additional fuel use by end-users and suggested that the corresponding<br />

section of AM0009 be brought into the methodology. The Panel also felt<br />

that unlike the facilities addressed in AM0009, those using the proposed<br />

methodology may construct new end-product facilities to produce<br />

methanol, ethylene or ammonia, thus having a possible effect on the<br />

international supply of these chemicals, and hence on activities outside<br />

the project boundary. The Panel concluded that this topic should be<br />

addressed in the leakage analysis and that the project boundary should<br />

explicitly include the production facilities for the end product.<br />

The methodology proposal was approved after revisions were made in<br />

response to the above concerns. Of particular note was that the treatment<br />

of baseline, project, and leakage emissions was based on the criterion that<br />

the project generated from CDM activities would otherwise have used a<br />

fuel and/or feedstock with equal or higher CO 2 equivalent emissions.<br />

October 2009 60