DEMO - 1965 Ford Truck Shop Manual - ForelPublishing.com

DEMO - 1965 Ford Truck Shop Manual - ForelPublishing.com

DEMO - 1965 Ford Truck Shop Manual - ForelPublishing.com

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

2-52 GROUP 2-BRAKES<br />

seats squarely on the slave cylinder<br />

body, and tighten the bushing securely.<br />

9. Coat the piston bores in the<br />

slave cylinder body with heavy-duty<br />

brake fluid. Dip the hydraulic cylinder<br />

piston, seals, spring retainer, and<br />

spring in the brake fluid.<br />

10. Install the hydraulic piston in<br />

the slave cylinder bore with the recessed<br />

end (or the large bore of the<br />

piston) toward the push rod bushing.<br />

Carefully position the piston cup<br />

with the recessed end toward the<br />

large spring, spring retainer, and<br />

spring on top of the piston.<br />

On a frame-mounted booster, install<br />

the spring seat in the spring<br />

coils.<br />

11. Position a new copper gasket<br />

on the end plug and screw the plug<br />

in the slave cylinder. Tighten the<br />

end plug securely.<br />

12. Dip the control valve piston<br />

and diaphragm in the heavy-duty<br />

CONTROL TUBE<br />

CONTROL VALVE BODY<br />

AIR INLET TUBE<br />

AND COVER<br />

SNAP RING<br />

SPRING<br />

SEAL<br />

brake fluid. Position the control<br />

valve spring on the diaphragm with<br />

the small end of the spring over the<br />

piston boss.<br />

13. Position the control valve<br />

body over the spring, align the scribe<br />

marks, install the valve body on the<br />

slave cylinder body and secure with<br />

4 attaching bolts and lock washers.<br />

Tighten the bolts securely.<br />

14. Position a new gasket on the<br />

control valve body, position the<br />

valve body cover over the gasket<br />

and secure the cover with 4 bolts<br />

and lock washers. Tighten the bolts<br />

securely.<br />

15. Position the collar over the<br />

threaded end of the push rod. Position<br />

the spring retainer in the spring<br />

as shown in the insert in Fig. 29. Insert<br />

the push rod and collar in the<br />

coils of the spring and through the<br />

retainer. Position the diaphragm<br />

over the threaded end of the push<br />

rod and secure it with the push rod<br />

RUBBER GASKET-<br />

CONTROL VALVE CYLINDER<br />

STOP WASHER<br />

GASKET •<br />

DIAPHRAGM<br />

nut. Tighten the nut securely. After<br />

the nut is tightened coat the threads<br />

of the push rod with shellac to prevent<br />

leakage. Coat the push rod with<br />

heavy-duty type brake fluid.<br />

16. Place the return spring over<br />

the push rod bushing.<br />

17. Place the rear body on top of<br />

the diaphragm with the scriber mark<br />

on the rear body in alignment with<br />

that on the front body. Compress<br />

the return spring, and install and<br />

tighten the clamp, making certain<br />

the diaphragm bead is properly positioned<br />

between the 2 halves of<br />

the body.<br />

18. Install the by-pass tube.<br />

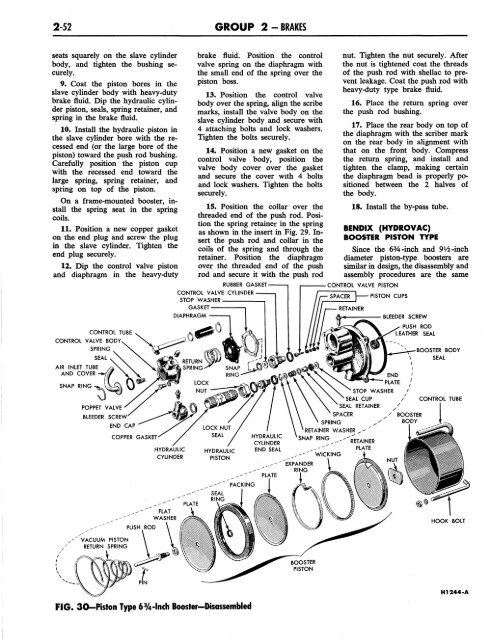

BENDIX (HYDROVAC)<br />

BOOSTER PISTON TYPE<br />

Since the 6%-inch and 9Vi-inch<br />

diameter piston-type boosters are<br />

similar in design, the disassembly and<br />

assembly procedures are the same<br />

CONTROL VALVE PISTON<br />

SPRING<br />

PISTON CUPS<br />

BLEEDER SCREW<br />

END<br />

PLATE<br />

STOP WASHER<br />

SEAL CUP<br />

SEAL RETAINER<br />

SPACER<br />

RETAINER WASHER<br />

SNAP RING<br />

PUSH ROD<br />

LEATHER SEAL<br />

BOOSTER BODY<br />

SEAL<br />

CONTROL TUBE<br />

HOOK BOLT<br />

BOOSTER<br />

PISTON<br />

FIG. 30-Piston Type 6%-lnch Booster-Disassembled<br />

H1244-A