TSUBAKI EMERSON CAM CLUTCH

TSUBAKI EMERSON CAM CLUTCH

TSUBAKI EMERSON CAM CLUTCH

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

www.bergab.ru Берг АБ bergab@ya.ru Тел. (495)-228-06-21, факс (495) 223-3071<br />

A-3. FREE WHEELING<br />

To prevent differences in the rotating speed between the<br />

driving side and the driven side from damaging the<br />

driving unit or the product, the Cam Clutch overruns<br />

when speed differences occur. Normally, the Cam Clutch<br />

engages to transmit torque, and it overruns to break the<br />

connection between the driving side and the driven side.<br />

In this case the Cam Clutch overruns at a speed equal to<br />

the difference in rotating speed that occurs when the<br />

driven unit (normally the inner race) rotates faster than<br />

the driving unit (normally the outer race), or when the<br />

driving unit is decelerated or stopped abruptly.<br />

When feeding hoop-shaped material or plate material to<br />

the next process by slitter or pressure rolls, the material is<br />

fed at first by pinch rolls up to the main rolls. Since the<br />

main rolls process the material while pulling it at a speed<br />

faster than that of the pinch rolls, the pinch rolls are<br />

pulled by the material. At this point, the Cam Clutch<br />

starts to overrun and prevents the pinch rolls from being<br />

driven in reverse by the material. The Cam Clutch is used<br />

to prevent damage to the pinch roll driving parts and to<br />

the material, due to slippage between the pinch rolls.<br />

This method is also used with drying machines, engine<br />

testers, and plywood fabricating machines.<br />

A-4. MANUAL TYPE<br />

Cam Clutches are used when a machine is operated<br />

manually for positioning, adjustment or inching. The<br />

Cam Clutch mounted at the manual handle overruns<br />

while the machine is in operation. The handle does not<br />

rotate and cause a safety hazard.<br />

Cam Clutches are used in the manual handles of<br />

circular knitting machines. The manual handle is used<br />

to operate the machine manually when starting, for<br />

adjustment of the needle and thread. When the<br />

machine starts its regular knitting work after the<br />

adjustment, the linkage between the Cam Clutch and<br />

the handle is broken. Another Cam Clutch is provided<br />

at the output section of the worm reduction gears, to<br />

break the connection with driving side during manual<br />

operation. Since this Cam Clutch engages to drive the<br />

circular knitting machine during regular operation, the<br />

large torque capacity PB12 is used.<br />

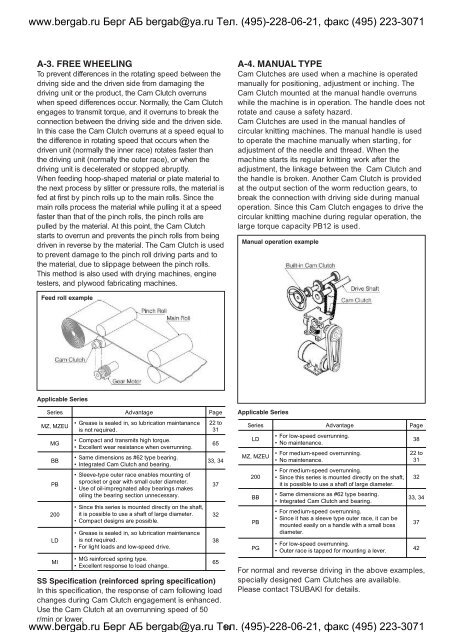

Manual operation example<br />

Feed roll example<br />

Applicable Series<br />

Series Advantage Page<br />

MZ, MZEU<br />

MG<br />

BB<br />

PB<br />

200<br />

LD<br />

MI<br />

• Grease is sealed in, so lubrication maintanance<br />

is not required.<br />

• Compact and transmits high torque.<br />

• Excellent wear resistance when overrunning.<br />

• Same dimensions as #62 type bearing.<br />

• Integrated Cam Clutch and bearing.<br />

• Sleeve-type outer race enables mounting of<br />

sprocket or gear with small outer diameter.<br />

• Use of oil-impregnated alloy bearings makes<br />

oiling the bearing section unnecessary.<br />

• Since this series is mounted directly on the shaft,<br />

it is possible to use a shaft of large diameter.<br />

• Compact designs are possible.<br />

• Grease is sealed in, so lubrication maintenance<br />

is not required.<br />

• For light loads and low-speed drive.<br />

• MG reinforced spring type.<br />

• Excellent response to load change.<br />

22 to<br />

31<br />

65<br />

33, 34<br />

37<br />

32<br />

38<br />

65<br />

Applicable Series<br />

Series Advantage Page<br />

LD<br />

MZ, MZEU<br />

200<br />

BB<br />

PB<br />

PG<br />

• For low-speed overrunning.<br />

• No maintenance.<br />

• For medium-speed overrunning.<br />

• No maintenance.<br />

• For medium-speed overrunning.<br />

• Since this series is mounted directly on the shaft,<br />

it is possible to use a shaft of large diameter.<br />

• Same dimensions as #62 type bearing.<br />

• Integrated Cam Clutch and bearing.<br />

• For medium-speed overrunning.<br />

• Since it has a sleeve type outer race, it can be<br />

mounted easily on a handle with a small boss<br />

diameter.<br />

• For low-speed overrunning.<br />

• Outer race is tapped for mounting a lever.<br />

SS Specification (reinforced spring specification)<br />

In this specification, the response of cam following load<br />

changes during Cam Clutch engagement is enhanced.<br />

Use the Cam Clutch at an overrunning speed of 50<br />

r/min or lower.<br />

www.bergab.ru Берг АБ bergab@ya.ru Тел. 14 (495)-228-06-21, факс (495) 223-3071<br />

38<br />

22 to<br />

31<br />

32<br />

33, 34<br />

For normal and reverse driving in the above examples,<br />

specially designed Cam Clutches are available.<br />

Please contact <strong>TSUBAKI</strong> for details.<br />

37<br />

42