TSUBAKI EMERSON CAM CLUTCH

TSUBAKI EMERSON CAM CLUTCH

TSUBAKI EMERSON CAM CLUTCH

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

www.bergab.ru Берг АБ bergab@ya.ru Тел. (495)-228-06-21, факс (495) 223-3071<br />

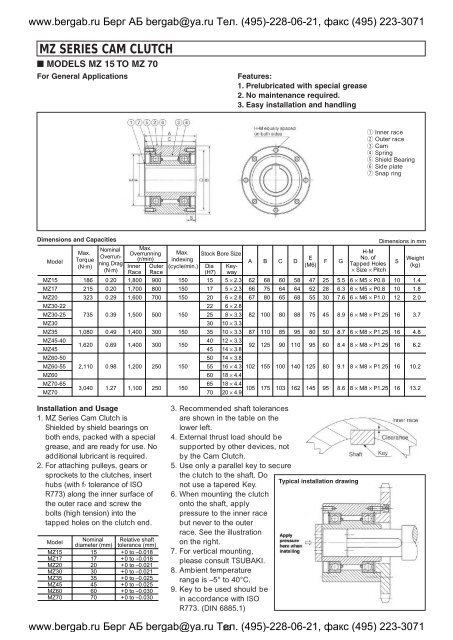

MZ SERIES <strong>CAM</strong> <strong>CLUTCH</strong><br />

■ MODELS MZ 15 TO MZ 70<br />

For General Applications<br />

Features:<br />

1. Prelubricated with special grease<br />

2. No maintenance required.<br />

3. Easy installation and handling<br />

q Inner race<br />

w Outer race<br />

e Cam<br />

r Spring<br />

t Shield Bearing<br />

y Side plate<br />

u Snap ring<br />

Dimensions and Capacities<br />

Model<br />

MZ15<br />

MZ17<br />

MZ20<br />

MZ30-22<br />

MZ30-25<br />

MZ30<br />

MZ35<br />

MZ45-40<br />

MZ45<br />

MZ60-50<br />

MZ60-55<br />

MZ60<br />

MZ70-65<br />

MZ70<br />

Max.<br />

Torque<br />

(N·m)<br />

186<br />

215<br />

323<br />

735<br />

1,080<br />

1,620<br />

2,110<br />

3,040<br />

Nominal<br />

Overrunning<br />

Drag<br />

(N·m)<br />

0.20<br />

0.20<br />

0.29<br />

0.39<br />

0.49<br />

0.69<br />

0.98<br />

1.27<br />

Max.<br />

Overrunning<br />

(r/min)<br />

Inner<br />

Race<br />

1,800<br />

1,700<br />

1,600<br />

1,500<br />

1,400<br />

1,400<br />

1,200<br />

1,100<br />

Outer<br />

Race<br />

900<br />

800<br />

700<br />

500<br />

300<br />

300<br />

250<br />

250<br />

Max.<br />

indexing<br />

(cycle/min.)<br />

150<br />

150<br />

150<br />

150<br />

150<br />

150<br />

150<br />

150<br />

Stock Bore Size<br />

Dia<br />

(H7)<br />

15<br />

17<br />

20<br />

22<br />

25<br />

30<br />

35<br />

40<br />

45<br />

50<br />

55<br />

60<br />

65<br />

70<br />

Keyway<br />

5 × 2.3<br />

5 × 2.3<br />

6 × 2.8<br />

6 × 2.8<br />

8 × 3.3<br />

10 × 3.3<br />

10 × 3.3<br />

12 × 3.3<br />

14 × 3.8<br />

14 × 3.8<br />

16 × 4.3<br />

18 × 4.4<br />

18 × 4.4<br />

20 × 4.9<br />

A<br />

62<br />

66<br />

67<br />

82<br />

87<br />

92<br />

102<br />

105<br />

B<br />

68<br />

75<br />

80<br />

100<br />

110<br />

125<br />

155<br />

175<br />

C<br />

60<br />

64<br />

65<br />

80<br />

85<br />

90<br />

100<br />

103<br />

D<br />

58<br />

64<br />

68<br />

88<br />

95<br />

110<br />

140<br />

162<br />

E<br />

(M6)<br />

47<br />

52<br />

55<br />

75<br />

80<br />

95<br />

125<br />

145<br />

F<br />

25<br />

28<br />

30<br />

45<br />

50<br />

60<br />

80<br />

95<br />

G<br />

5.5<br />

6.3<br />

7.6<br />

8.9<br />

8.7<br />

8.4<br />

9.1<br />

8.6<br />

H-M<br />

No. of<br />

Tapped Holes<br />

× Size × Pitch<br />

6 × M5 × P0.8<br />

6 × M5 × P0.8<br />

6 × M6 × P1.0<br />

6 × M8 × P1.25<br />

6 × M8 × P1.25<br />

8 × M8 × P1.25<br />

8 × M8 × P1.25<br />

8 × M8 × P1.25<br />

Dimensions in mm<br />

S<br />

10<br />

10<br />

12<br />

16<br />

16<br />

16<br />

16<br />

16<br />

Weight<br />

(kg)<br />

1.4<br />

1.8<br />

2.0<br />

3.7<br />

4.8<br />

6.2<br />

10.2<br />

13.2<br />

Installation and Usage<br />

1. MZ Series Cam Clutch is<br />

Shielded by shield bearings on<br />

both ends, packed with a special<br />

grease, and are ready for use. No<br />

additional lubricant is required.<br />

2. For attaching pulleys, gears or<br />

sprockets to the clutches, insert<br />

hubs (with f7 tolerance of ISO<br />

R773) along the inner surface of<br />

the outer race and screw the<br />

bolts (high tension) into the<br />

tapped holes on the clutch end.<br />

Model<br />

MZ15<br />

MZ17<br />

MZ20<br />

MZ30<br />

MZ35<br />

MZ45<br />

MZ60<br />

MZ70<br />

Nominal<br />

diameter (mm)<br />

15<br />

17<br />

20<br />

30<br />

35<br />

45<br />

60<br />

70<br />

Relative shaft<br />

tolerance (mm)<br />

+0 to –0.018<br />

+0 to –0.018<br />

+0 to –0.021<br />

+0 to –0.021<br />

+0 to –0.025<br />

+0 to –0.025<br />

+0 to –0.030<br />

+0 to –0.030<br />

3. Recommended shaft tolerances<br />

are shown in the table on the<br />

lower left.<br />

4. External thrust load should be<br />

supported by other devices, not<br />

by the Cam Clutch.<br />

5. Use only a parallel key to secure<br />

the clutch to the shaft. Do<br />

Typical installation drawing<br />

not use a tapered Key.<br />

6. When mounting the clutch<br />

onto the shaft, apply<br />

pressure to the inner race<br />

but never to the outer<br />

race. See the illustration<br />

on the right.<br />

7. For vertical mounting,<br />

please consult <strong>TSUBAKI</strong>.<br />

8. Ambient temperature<br />

range is –5° to 40°C.<br />

9. Key to be used should be<br />

in accordance with ISO<br />

R773. (DIN 6885.1)<br />

www.bergab.ru Берг АБ bergab@ya.ru Тел. 22 (495)-228-06-21, факс (495) 223-3071