TSUBAKI EMERSON CAM CLUTCH

TSUBAKI EMERSON CAM CLUTCH

TSUBAKI EMERSON CAM CLUTCH

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

www.bergab.ru Берг АБ bergab@ya.ru Тел. (495)-228-06-21, факс (495) 223-3071<br />

B-4. BACKSTOPPING IN INTERMITTENT<br />

FEEDING<br />

Cam clutch and feed accuracy<br />

When designing a high-accuracy feeding device that<br />

incorporates Cam Clutch indexing, both the driving<br />

and driven units must be made light in weight and high<br />

in rigidity. Moreover, when selecting the ideal Cam<br />

Clutch, it is extremely important to select a brake to<br />

stop the driven unit at a preset position, a positioning<br />

device, and a Cam Clutch for backstopping (which<br />

cannot be expected of the Cam Clutch for indexing).<br />

Feed accuracy = Cam Clutch for indexing +<br />

Cam Clutch for backstop + Brake<br />

Cam Clutch for backstopping<br />

This Cam Clutch overruns<br />

when the Cam Clutch for<br />

indexing has completed one<br />

feeding stroke. If the frictional<br />

resistance of the driven unit<br />

is smaller than the<br />

overrunning frictional torque<br />

of the Cam Clutch, or if a<br />

reverse torque occurs on the<br />

driving side due to back<br />

MX Series<br />

tension of the material, the<br />

driven unit may rotate in reverse without stopping at<br />

the end point fed by the Cam Clutch. The most<br />

effective way to prevent this is to mount a Cam Clutch<br />

for backstopping, although a brake or positioning pin<br />

may also be used for this purpose. Since the Cam<br />

Clutch for backstopping repeats the overrunning and<br />

engagement at the same frequency as that of the Cam<br />

Clutch for indexing, use one that is equivalent to the<br />

feeding clutch or one that is one size smaller.<br />

Brakes and other stopping devices<br />

The outer race of a Cam<br />

Clutch for indexing starts<br />

reverse rotation immediately<br />

upon the completion of one<br />

feeding stroke. At the same<br />

time, the Cam Clutch starts<br />

overrunning. At this moment,<br />

the driven unit is free from all<br />

restrictions, and therefore,<br />

when the driven unit has a<br />

Cone brake<br />

larger inertia or the feed<br />

speed is faster, the inner race tends to rotate beyond<br />

the stroke of the outer race. To prevent this, a friction<br />

brake is often used as a braking device, although a<br />

positioning pin or stopper may also be used for this<br />

purpose. A braking device significantly improves the<br />

feed accuracy. Accordingly, use a frictional brake which<br />

has as small a fluctuation as possible in its braking<br />

force. The wet-type cone brake is most effective. Please<br />

consult <strong>TSUBAKI</strong> regarding brake selection.<br />

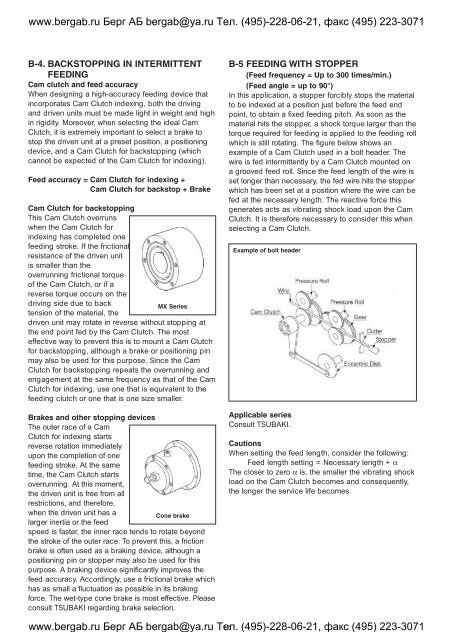

B-5 FEEDING WITH STOPPER<br />

(Feed frequency = Up to 300 times/min.)<br />

(Feed angle = up to 90°)<br />

In this application, a stopper forcibly stops the material<br />

to be indexed at a position just before the feed end<br />

point, to obtain a fixed feeding pitch. As soon as the<br />

material hits the stopper, a shock torque larger than the<br />

torque required for feeding is applied to the feeding roll<br />

which is still rotating. The figure below shows an<br />

example of a Cam Clutch used in a bolt header. The<br />

wire is fed intermittently by a Cam Clutch mounted on<br />

a grooved feed roll. Since the feed length of the wire is<br />

set longer than necessary, the fed wire hits the stopper<br />

which has been set at a position where the wire can be<br />

fed at the necessary length. The reactive force this<br />

generates acts as vibrating shock load upon the Cam<br />

Clutch. It is therefore necessary to consider this when<br />

selecting a Cam Clutch.<br />

Example of bolt header<br />

Applicable series<br />

Consult <strong>TSUBAKI</strong>.<br />

Cautions<br />

When setting the feed length, consider the following:<br />

Feed length setting = Necessary length + α<br />

The closer to zero α is, the smaller the vibrating shock<br />

load on the Cam Clutch becomes and consequently,<br />

the longer the service life becomes.<br />

www.bergab.ru Берг АБ bergab@ya.ru Тел. 17 (495)-228-06-21, факс (495) 223-3071