TSUBAKI EMERSON CAM CLUTCH

TSUBAKI EMERSON CAM CLUTCH

TSUBAKI EMERSON CAM CLUTCH

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

www.bergab.ru Берг АБ bergab@ya.ru Тел. (495)-228-06-21, факс (495) 223-3071<br />

■ INFORMATION FOR SELECTION<br />

Selection Procedure<br />

1. Determine the mode of operation (indexing,<br />

overrunning, or backstopping).<br />

2. Refer to the selection procedure corresponding to<br />

the mode of operation.<br />

Indexing<br />

a) When detailed load conditions can be calculated,<br />

apply formula A, and when not, apply formula B<br />

and check the torque on the Cam Clutch.<br />

b) Select the clutch by:<br />

a) Design torque requirement<br />

b) Maximum indexing cycles N<br />

c) Feeding angle θ<br />

θ≥90°....MI-S<br />

θ < 90°....Other series<br />

d) N × θ<br />

N × θ≤20,000....MZ, PB, 200, MI, MX, PO,<br />

PG, PS<br />

N × θ≤50,000....MI-S<br />

e) Bore size and installation method<br />

Note: MX Series are designed especially for highspeed<br />

and high-accuracy indexing. Please<br />

consult <strong>TSUBAKI</strong> for proper selection.<br />

9550·kW<br />

T = × SF<br />

N<br />

T: Loaded torque (N·m)<br />

kW:Transmitted power (kW)<br />

N: Speed of Cam Clutch shaft rotation (r/min)<br />

SF: Service factor<br />

b) Select clutch by:<br />

a) Design torque requirement and service factor<br />

b) Maximum overrunning speed<br />

c) Bore and installation method<br />

If the SF is not known, use the peak torque<br />

with shock factor method.<br />

Type of Load<br />

No shock load<br />

Moderate shock load<br />

Shock load<br />

Heavy shock load<br />

SF<br />

1 – 1.5<br />

1.5 – 2.5<br />

2 – 3<br />

4 – 6<br />

SF = Motor peak torque at staring x shock factor, K.<br />

The shock factor K is obtained from the chart<br />

below by calculating inertia ratio. Use a shock<br />

factor of K = 1 when the inertia ratio is below 0.48.<br />

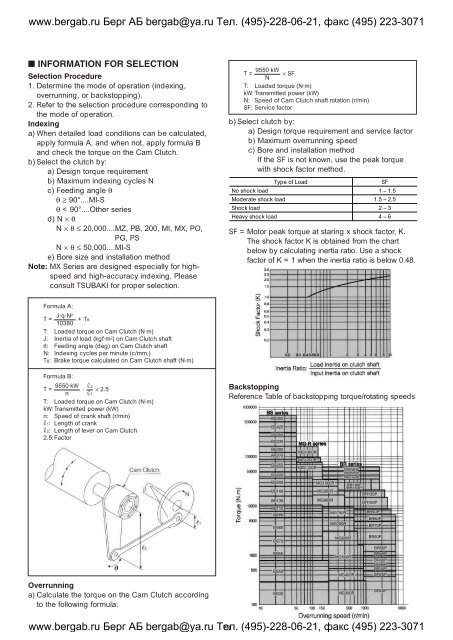

Formula A:<br />

T =<br />

J·q·N 2<br />

10380<br />

+ TB<br />

T: Loaded torque on Cam Clutch (N·m)<br />

J: Inertia of load (kgf·m 2 ) on Cam Clutch shaft<br />

θ: Feeding angle (deg) on Cam Clutch shaft<br />

N: Indexing cycles per minute (c/mm.)<br />

TB: Brake torque calculated on Cam Clutch shaft (N·m)<br />

Formula B:<br />

9550·kW r2<br />

T = · × 2.5<br />

n r1<br />

T: Loaded torque on Cam Clutch (N·m)<br />

kW:Transmitted power (kW)<br />

n: Speed of crank shaft (r/min)<br />

r1: Length of crank<br />

r2: Length of lever on Cam Clutch<br />

2.5:Factor<br />

Backstopping<br />

Reference Table of backstopping torque/rotating speeds<br />

BS450<br />

BS425<br />

BS350<br />

BS335<br />

BS300<br />

BS270<br />

BS250<br />

BS220<br />

BS200<br />

BS160<br />

BS135<br />

BS110<br />

BS95<br />

BS85<br />

MG1300R<br />

MG1200R<br />

MG1100R<br />

MG1000R<br />

MG900R<br />

MG800R<br />

MG750R<br />

MG700R<br />

BR240P<br />

BR220P<br />

BR190P<br />

BR180P<br />

(BR150P)<br />

BR130P<br />

BR100P<br />

BR90P<br />

BR80P<br />

BR70P<br />

BS75<br />

MG600R<br />

BR60P<br />

BS65<br />

BS50<br />

MG500R<br />

MG400R<br />

BR50P<br />

BR45P<br />

BR40P<br />

BR35P<br />

BR30P<br />

BR25P<br />

Overrunning<br />

a) Calculate the torque on the Cam Clutch according<br />

to the following formula:<br />

BS30<br />

MG300R<br />

BR20P<br />

www.bergab.ru Берг АБ bergab@ya.ru Тел. 73 (495)-228-06-21, факс (495) 223-3071