Chapter 3 Wiring Methods and Materials

Chapter 3 Wiring Methods and Materials

Chapter 3 Wiring Methods and Materials

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

ARTICLE 31O-CONDUCTORS FOR GENERAL WIRING<br />

310.15<br />

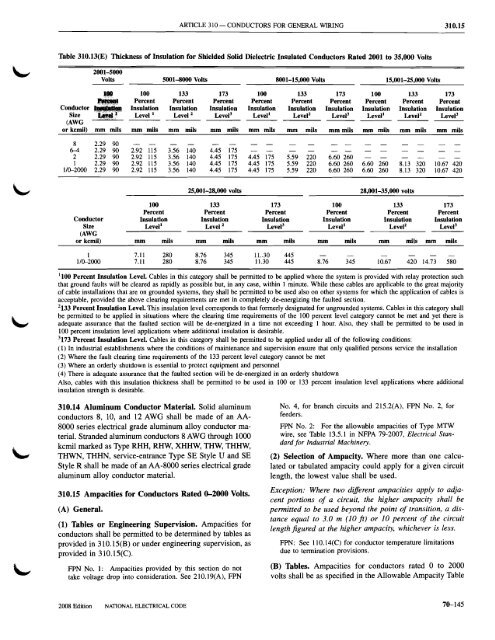

Table 310.13(E) Thickness of Insulation for Shielded Solid Dielectric Insulated Conductors Rated 2001 to 35,000 Volts<br />

2001-5000<br />

....<br />

Volts 5001-8000 Volts 8001-15,000 Volts 15,001-25,000 Volts<br />

100 133 173 100 133 173 100 133 173<br />

• Percent<br />

MPJ'<br />

Percent Percent Percent Percent Percent Percent Percent Percent<br />

Conductor Insulation Insulation Insulation Insulation Insulation Insulation Insulation Insulation Insulation<br />

Size ~J ,c··" .. ;<br />

Levell Level 2 Levee Levell Level 2 Level 3 Levell Level 2 Level 3<br />

(AWG<br />

or kcmil) mm mils mm mils mm mils mm mils mm mils mm mils mm mils mm mils mm mils mm mils<br />

8 2.29 90<br />

6-4 2.29 90 2.92 115 3.56 140 4.45 175<br />

2 2.29 90 2.92 115 3.56 140 4.45 175 4.45 175 5.59 220 6.60 260<br />

1 2.29 90 2.92 115 3.56 140 4.45 175 4.45 175 5.59 220 6.60 260 6.60 260 8.13 320 10.67 420<br />

1/0-2000 2.29 90 2.92 115 3.56 140 4.45 175 4.45 175 5.59 220 6.60 260 6.60 260 8.13 320 10.67 420<br />

25,001-28,000 volts 28,001-35,000 volts<br />

Conductor<br />

Size<br />

(AWG<br />

or kcmil)<br />

100<br />

Percent<br />

Insulation<br />

Levell<br />

mm<br />

mils<br />

133<br />

Percent<br />

Insulation<br />

Level 2<br />

mm<br />

mils<br />

173<br />

Percent<br />

Insulation<br />

Level 3<br />

mm<br />

mils<br />

100<br />

Percent<br />

Insulation<br />

Levell<br />

mm<br />

mils<br />

133<br />

Percent<br />

Insulation<br />

Level 2<br />

mm<br />

mils<br />

mm<br />

173<br />

Percent<br />

Insulation<br />

Level 3<br />

mils<br />

1<br />

1/0-2000<br />

7.11<br />

7.11<br />

280<br />

280<br />

8.76<br />

8.76<br />

345<br />

345<br />

11..30<br />

11.30<br />

445<br />

445 8.76 345 10.67 420 14.73 580<br />

1100 Percent Insulation Level. Cables in this category shall be pennitted to be applied where the system is provided with relay protection such<br />

that ground faults will be cleared as rapidly as possible but, in any case, within 1 minute. While these cables are applicable to the great majority<br />

of cable installations that are on grounded systems, they shall be permitted to be used also on other systems for which the application of cables is<br />

acceptable, provided the above clearing requirements are met in completely de-energizing the faulted section.<br />

2133 Percent Insulation Level. This insulation level corresponds to that formerly designated for ungrounded systems. Cables in this category shall<br />

be permitted to be applied in situations where the clearing time requirements of the 100 percent level category cannot be met <strong>and</strong> yet there is<br />

adequate assurance that the faulted section will be de-energized in a time not exceeding I hour. Also, they shall be permitted to be used in<br />

100 percent insulation level applications where additional insulation is desirable.<br />

3173 Percent Insulation Level. Cables in this category shall be permitted to be applied under all of the following conditions:<br />

(I) In industrial establishments where the conditions of maintenance <strong>and</strong> supervision ensure that only qualified persons service the installation<br />

(2) Where the fault clearing time requirements of the 133 percent level category cannot be met<br />

(3) Where an orderly shutdown is essential to protect equipment <strong>and</strong> personnel<br />

(4) There is adequate assurance that the faulted section will be de-energized in an orderly shutdown<br />

Also, cables with this insulation thickness shall be permitted to be used in 100 or 133 percent insulation level applications where additional<br />

insulation strength is desirable.<br />

310.14 Aluminum Conductor Material. Solid aluminum No.4, for branch circuits <strong>and</strong> 215.2(A), FPN No.2, for<br />

conductors 8, 10, <strong>and</strong> 12 AWG shall be made of an AAfeeders.<br />

8000 series electrical grade aluminum alloy conductor ma FPN No.2: For the allowable ampacities of Type MTW<br />

terial. Str<strong>and</strong>ed aluminum conductors 8 AWG through 1000 wire, see Table 13.5.1 in NFPA 79-2007, Electrical Stan<br />

dard for Industrial Machinery.<br />

kcmil marked as Type RHH, RHW, XHHW, THW, THHW,<br />

THWN, THHN, service-entrance Type SE Style U <strong>and</strong> SE (2) Selection of Ampacity. Where more than one calcu<br />

Style R shall be made of an AA-8000 series electrical grade lated or tabulated ampacity could apply for a given circuit<br />

aluminum alloy conductor material.<br />

length, the lowest value shall be used.<br />

310.15 Ampacities for Conductors Rated 0-2000 Volts.<br />

(A) General.<br />

(1) Tables or Engineering Supervision. Ampacities for<br />

conductors shall be permitted to be determined by tables as<br />

provided in 310.15(B) or under engineering supervision, as<br />

provided in 3l0.l5(C).<br />

FPN No.1: Ampacities provided by this section do not<br />

take voltage drop into consideration. See 210.19(A), FPN<br />

Exception: Where two different ampacities apply to adjacent<br />

portions of a circuit, the higher ampacity shall be<br />

permitted to be used beyond the point of transition, a distance<br />

equal to 3.0 m (10 ft) or 10 percent of the circuit<br />

length figured at the higher ampacity, whichever is less.<br />

FPN: See llO.14(C) for conductor temperature limitations<br />

due to termination provisions.<br />

(B) Tables. Ampacities for conductors rated 0 to 2000<br />

volts shall be as specified in the Allowable Ampacity Table<br />

2008 Edition NATIONAL ELECTRICAL CODE 70-145