Chapter 3 Wiring Methods and Materials

Chapter 3 Wiring Methods and Materials

Chapter 3 Wiring Methods and Materials

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

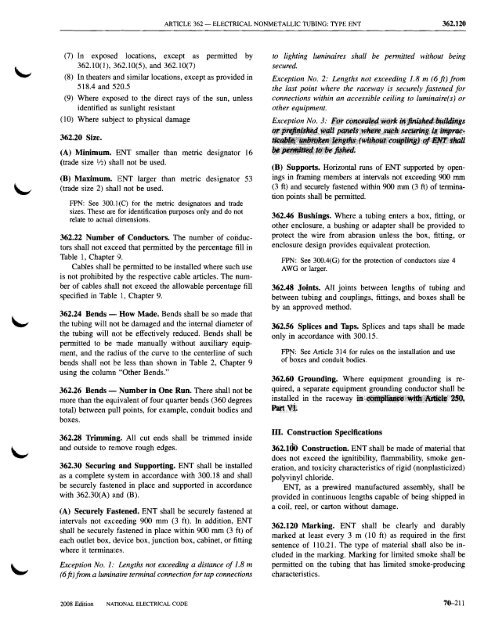

ARTICLE 362 -<br />

ELECTRICAL NONMETALLIC TUBING: TYPE ENT<br />

362.120<br />

(7) In exposed locations, except as permitted by<br />

362.10(1), 362.10(5), <strong>and</strong> 362.10(7)<br />

(8) In theaters <strong>and</strong> similar locations, except as provided in<br />

518.4 <strong>and</strong> 520.5<br />

(9) Where exposed to the direct rays of the sun, unless<br />

identified as sunlight resistant<br />

(10) Where subject to physical damage<br />

to lighting luminaires shall be pennitted without being<br />

secured.<br />

Exception No.2: Lengths not exceeding 1.8 m (6 ft) from<br />

the last point where the raceway is securely fastened for<br />

connections within an accessible ceiling to luminaire(s) or<br />

other equipment.<br />

Exception No.3:<br />

362.20 Size.<br />

(A) Minimum. ENT smaller than metric designator 16<br />

(trade size 1/2) shall not be used.<br />

(B) Maximum. ENT larger than metric designator 53<br />

(trade size 2) shall not be used.<br />

FPN: See 300.1 (C) for the metric designators <strong>and</strong> trade<br />

sizes. These are for identification purposes only <strong>and</strong> do not<br />

relate to actual dimensions.<br />

362.22 Number of Conductors. The number of conductors<br />

shall not exceed that permitted by the percentage fill in<br />

Table 1, <strong>Chapter</strong> 9.<br />

Cables shall be permitted to be installed where such use<br />

is not prohibited by the respective cable articles. The number<br />

of cables shall not exceed the allowable percentage fill<br />

specified in Table 1, <strong>Chapter</strong> 9.<br />

362.24 Bends - How Made. Bends shall be so made that<br />

the tubing will not be damaged <strong>and</strong> the internal diameter of<br />

the tubing will not be effectively reduced. Bends shall be<br />

permitted to be made manually without auxiliary equipment,<br />

<strong>and</strong> the radius of the curve to the centerline of such<br />

bends shall not be less than shown in Table 2, <strong>Chapter</strong> 9<br />

using the column "Other Bends."<br />

362.26 Bends -, Number in One Run. There shall not be<br />

more than the equivalent of four quarter bends (360 degrees<br />

total) between pull points, for example, conduit bodies <strong>and</strong><br />

boxes.<br />

362.28 Trimming. All cut ends shall be trimmed inside<br />

<strong>and</strong> outside to remove rough edges.<br />

362.30 Securing <strong>and</strong> Supporting. ENT shall be installed<br />

as a complete system in accordance with 300.18 <strong>and</strong> shall<br />

be securely fastened in place <strong>and</strong> supported in accordance<br />

with 362.30(A) <strong>and</strong> (B).<br />

(A) Securely Fastened. ENT shall be securely fastened at<br />

intervals not exceeding 900 mm (3 ft). In addition, ENT<br />

shall be securely fastened in place within 900 mm (3 ft) of<br />

each outlet box, device box, junction box, cabinet, or fitting<br />

where it terminaJ:es.<br />

Exception No.1: Lengths not exceeding a distance of 1.8 m<br />

(6ft) from a luminaire tenninal connection for tap connections<br />

(B) Supports. Horizontal runs of ENT supported by openings<br />

in framing members at intervals not exceeding 900 rom<br />

(3 ft) <strong>and</strong> securely fastened within 900 rom (3 ft) of termination<br />

points shall be permitted.<br />

362.46 Bushings. Where a tubing enters a box, fitting, or<br />

other enclosure, a bushing or adapter shall be provided to<br />

protect the wire from abrasion unless the box, fitting, or<br />

enclosure design provides equivalent protection.<br />

FPN: See 3oo.4(G) for the protection of conductors size 4<br />

AWG or larger.<br />

362.48 Joints. All joints between lengths of tubing <strong>and</strong><br />

between tubing <strong>and</strong> couplings, fittings, <strong>and</strong> boxes shall be<br />

by an approved method.<br />

362.56 Splices <strong>and</strong> Taps. Splices <strong>and</strong> taps shall be made<br />

only in accordance with 300.15.<br />

FPN: See Article 314 for rules on the installation <strong>and</strong> use<br />

of boxes <strong>and</strong> conduit bodies.<br />

362.60 Grounding. Where equipment grounding is required,<br />

a separate equipment grounding conductor shall be<br />

installed in the raceway bt:_IJl!Iit_~:,rt,ro~~~mi~_r'!.!o.<br />

PUt vi.<br />

III. Construction Specifications<br />

362.100 Construction. ENT shall be made of material that<br />

does not exceed the ignitibility, flammability, smoke generation,<br />

<strong>and</strong> toxicity characteristics of rigid (nonplasticized)<br />

polyvinyl chloride.<br />

ENT, as a prewired manufactured assembly, shall be<br />

provided in continuous lengths capable of being shipped in<br />

a coil, reel, or carton without damage.<br />

362.120 Marking. ENT shall be clearly <strong>and</strong> durably<br />

marked at least every 3 m (10 ft) as required in the first<br />

sentence of 110.21. The type of material shall also be included<br />

in the marking. Marking for limited smoke shall be<br />

permitted on the tubing that has limited smoke-producing<br />

characteristics.<br />

2008 Edition NATIONAL ELECTRICAL CODE<br />

70-211