Chapter 3 Wiring Methods and Materials

Chapter 3 Wiring Methods and Materials

Chapter 3 Wiring Methods and Materials

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

324.60 ARTICLE 326 - INTEGRATED GAS SPACER CABLE: lYPE lOS<br />

conductors, <strong>and</strong> for electrically connecting the assembly to the<br />

metal cable shields <strong>and</strong> to equipment grounding conductors.<br />

324.60 Grounding. All metal shields, boxes, receptacle<br />

housings, <strong>and</strong> self-contained devices shall be electrically<br />

continuous to the equipment grounding conductor of the<br />

supplying branch circuit. All such electrical connections<br />

shall be made with connectors identified for this use. The<br />

electrical resistivity of such shield system shall not be more<br />

than that of one conductor of the 'Jype FCC cable used in<br />

the installation.<br />

DI. Construction<br />

324.100 Construction.<br />

(A) Type FCC Cable. Type FCC cable shall be listed for<br />

use with the FCC system <strong>and</strong> shall consist of three, four, or<br />

five flat copper conductors, one of which shall be an equipment<br />

grounding conductor.<br />

(B) Shields.<br />

(1) <strong>Materials</strong> <strong>and</strong> Dimensions. All top <strong>and</strong> bottom shields<br />

shall be of designs <strong>and</strong> materials identified for their use.<br />

Top shields shall be metal. Both metallic <strong>and</strong> nonmetallic<br />

materials shall be permitted for bottom shields.<br />

(2) Resistivity. Metal shields shall have cross-sectional areas<br />

that provide for electrical resistivity of not more than<br />

that of one conductor of the Type FCC cable used in the<br />

installation.<br />

324.101 Corrosion Resistance. Metal components of the<br />

system shall be either corrosion resistant, coated with<br />

corrosion-resistant materials, or insulated from contact with<br />

corrosive substances.<br />

324.112 Insulation. The insulating material of the cable<br />

shall be moisture resistant <strong>and</strong> flame retardant. All insulating<br />

materials in the FCC systems shall be identified for<br />

their use.<br />

324.120 Markings.<br />

(A) Cable Marking. Type FCC cable shall be clearly <strong>and</strong><br />

durably marked on both sides at intervals of not more than<br />

610 mm (24 in.) with the information required by<br />

310.11 (A) <strong>and</strong> with the following additional information:<br />

(1) Material of conductors<br />

(2) Maximum temperature rating<br />

(3) Ampacity<br />

(B) Conductor Identification. Conductors shall be clearly<br />

<strong>and</strong> durably identified on both sides throughout their length<br />

as specified in 310.12.<br />

I. General<br />

326.1 Scope. This article covers the use, installation, <strong>and</strong><br />

construction specifications for integrated gas spacer cable,<br />

Type IGS.<br />

326.2 Definition.<br />

Integrated Gas Spacer Cable, Type IGS. A factory assembly<br />

of one or more conductors, each individually insulated <strong>and</strong><br />

enclosed in a loose fit, nonmetallic flexible conduit as an integrated<br />

gas spacer cable rated 0 through 600 volts.<br />

II. Installation<br />

326.10 Uses Permitted. Type IGS cable shall be permitted<br />

for use under ground, including direct burial in the earth, as<br />

the following:<br />

(1) Service-entrance conductors<br />

(2) Feeder or branch-circuit conductors<br />

326.12 Uses Not Permitted. Type IGS cable shall not be<br />

used as interior wiring or be exposed in contact with buildings.<br />

326.24 Bending Radius. Where the coilable nonmetallic<br />

conduit <strong>and</strong> cable is bent for installation purposes or is<br />

flexed or bent during shipment or installation, the radii of<br />

bends measured to the inside of the bend shall not be less<br />

than specified in Table 326.24.<br />

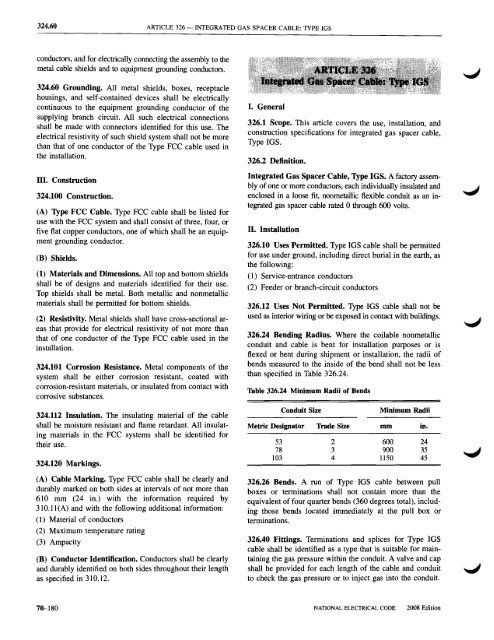

Table 326.24 Minimum Radii of Bends<br />

Conduit Size<br />

Minimum Radii<br />

Metric Designator Trade Size mm in.<br />

53 2 600 24<br />

78 3 900 35<br />

103 4 1150 45<br />

326.26 Bends. A run of Type IGS cable between pull<br />

boxes or terminations shall not contain more than the<br />

equivalent of four quarter bends (360 degrees total), including<br />

those bends located immediately at the pull box or<br />

terminations.<br />

326.40 Fittings. Terminations <strong>and</strong> splices for Type IGS<br />

cable shall be identified as a type that is suitable for maintaining<br />

the gas pressure within the conduit. A valve <strong>and</strong> cap<br />

shall be provided for each length of the cable <strong>and</strong> conduit<br />

to check the gas pressure or to inject gas into the conduit.<br />

70--180<br />

NATIONAL ELECTRICAL CODE<br />

2008 Edition