Hep20 Technical Handbook

Hep20 Technical Handbook

Hep20 Technical Handbook

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Hep 2<br />

O ® Design Considerations<br />

Systems Planning<br />

Access to Pipes and Joints<br />

The Hep 2 O ® Routabout System<br />

Hep 2 O ® Routabout Hole Cutter is<br />

a unique system that solves the<br />

problem of underfloor access found<br />

by all builders, plumbers and other<br />

trades. A 250mm diameter opening<br />

can be cut and made good in<br />

minutes. Designed for use in new or<br />

existing 18mm and 22mm chipboard<br />

or similar floors, the Routabout cuts<br />

only the thickness of the board, thus<br />

leaving no waste, and the piece cut<br />

out is used to make good the floor.<br />

The Routabout starter kit contains:<br />

1 x Routabout Rotating Template.<br />

•<br />

1 x Routabout Tungsten Cutter.<br />

•<br />

4 x Routabout Spacer Rings.<br />

(Additional rings are available separately)<br />

•<br />

1 x 25mm x No. 8 chipboard screw.<br />

Refer to Product Range page 40.<br />

Also needed, but not supplied:<br />

•<br />

A medium sized plunging type router (750<br />

watts min).<br />

• 1 x 1 / 4’’ or 1 / 2’’ collet to fit router.<br />

•<br />

1 x 30mm (outside dia) guide bush fitted<br />

to the router.<br />

Forming an access point to underfloor<br />

services (stages 1 to 4)<br />

1<br />

The equipment:<br />

Plunging type router.<br />

Routabout Tungsten Cutter.<br />

Routabout Rotating Template.<br />

•<br />

Routabout Spacer Ring.<br />

2<br />

Routing the flooring sheet using the Routabout<br />

Rotating Template.<br />

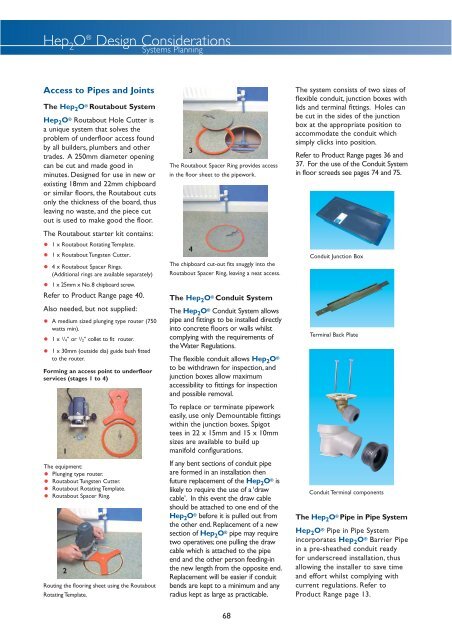

3<br />

The Routabout Spacer Ring provides access<br />

in the floor sheet to the pipework.<br />

4<br />

The chipboard cut-out fits snuggly into the<br />

Routabout Spacer Ring, leaving a neat access.<br />

The Hep 2 O ® Conduit System<br />

The Hep 2 O ® Conduit System allows<br />

pipe and fittings to be installed directly<br />

into concrete floors or walls whilst<br />

complying with the requirements of<br />

the Water Regulations.<br />

The flexible conduit allows Hep 2 O ®<br />

to be withdrawn for inspection, and<br />

junction boxes allow maximum<br />

accessibility to fittings for inspection<br />

and possible removal.<br />

To replace or terminate pipework<br />

easily, use only Demountable fittings<br />

within the junction boxes. Spigot<br />

tees in 22 x 15mm and 15 x 10mm<br />

sizes are available to build up<br />

manifold configurations.<br />

If any bent sections of conduit pipe<br />

are formed in an installation then<br />

future replacement of the Hep 2 O ® is<br />

likely to require the use of a ‘draw<br />

cable’. In this event the draw cable<br />

should be attached to one end of the<br />

Hep 2 O ® before it is pulled out from<br />

the other end. Replacement of a new<br />

section of Hep 2 O ® pipe may require<br />

two operatives; one pulling the draw<br />

cable which is attached to the pipe<br />

end and the other person feeding-in<br />

the new length from the opposite end.<br />

Replacement will be easier if conduit<br />

bends are kept to a minimum and any<br />

radius kept as large as practicable.<br />

68<br />

The system consists of two sizes of<br />

flexible conduit, junction boxes with<br />

lids and terminal fittings. Holes can<br />

be cut in the sides of the junction<br />

box at the appropriate position to<br />

accommodate the conduit which<br />

simply clicks into position.<br />

Refer to Product Range pages 36 and<br />

37. For the use of the Conduit System<br />

in floor screeds see pages 74 and 75.<br />

Conduit Junction Box<br />

Terminal Back Plate<br />

Conduit Terminal components<br />

The Hep 2 O ® Pipe in Pipe System<br />

Hep 2 O ® Pipe in Pipe System<br />

incorporates Hep 2 O ® Barrier Pipe<br />

in a pre-sheathed conduit ready<br />

for underscreed installation, thus<br />

allowing the installer to save time<br />

and effort whilst complying with<br />

current regulations. Refer to<br />

Product Range page 13.