Hep20 Technical Handbook

Hep20 Technical Handbook

Hep20 Technical Handbook

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Hep 2<br />

O ® Design Considerations<br />

Construction & Water Distribution<br />

Hep 2 O ® Within Drylined<br />

Walls<br />

Feeds to radiators run in microbore<br />

copper can be accommodated<br />

behind ‘dot and dab’ plasterboard to<br />

give a pipe-free appearance within<br />

the room. Pipes run in 10mm<br />

Hep 2 O ® are equally suited to this<br />

application but will not be<br />

susceptible to damage such as dents<br />

or kinks which can be caused on<br />

‘soft’ copper by following tradesmen.<br />

The penetration through the<br />

plasterboard for a radiator<br />

connection can be achieved by using<br />

a 10mm SlimLine Elbow (HX5/10)<br />

together with a Fitting Clip<br />

(HX84/10) or alternatively a dry<br />

lining box can be used. See Figure 28<br />

on page 78.<br />

Another method when using 10mm<br />

Hep 2 O ® Pipe is to utilise the<br />

HX111 Cover Plate. The HX111<br />

Cover Plate and Back Box (HX109<br />

or HX110) allows for a superior and<br />

easy to install method of connecting<br />

radiators. The box is fixed in a<br />

central position behind the radiator<br />

with the 10mm pipes dropping out<br />

to the radiator valves. This gives a<br />

smart professional finish where little<br />

or no pipe is seen and for new build<br />

provides an anchor point for the<br />

pipe work prior to<br />

plastering/boarding.<br />

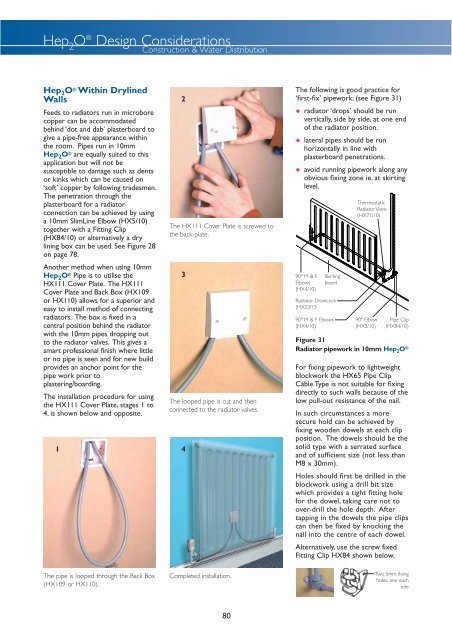

The installation procedure for using<br />

the HX111 Cover Plate, stages 1 to<br />

4, is shown below and opposite.<br />

1<br />

2<br />

The HX111 Cover Plate is screwed to<br />

the back-plate.<br />

3<br />

The looped pipe is cut and then<br />

connected to the radiator valves.<br />

4<br />

The following is good practice for<br />

‘first-fix’ pipework: (see Figure 31)<br />

• radiator ‘drops’ should be run<br />

vertically, side by side, at one end<br />

of the radiator position.<br />

• lateral pipes should be run<br />

horizontally in line with<br />

plasterboard penetrations.<br />

• avoid running pipework along any<br />

obvious fixing zone ie. at skirting<br />

level.<br />

90º M & F<br />

Elbows<br />

(HX4/10)<br />

Skirting<br />

board<br />

Radiator Draincock<br />

(HX23/15<br />

90º M & F Elbows<br />

(HX4/10)<br />

Thermostatic<br />

Radiator Valve<br />

(HX71/10)<br />

90º Elbow<br />

(HX5/10)<br />

Pipe Clip<br />

(HX84/10)<br />

Figure 31<br />

Radiator pipework in 10mm Hep 2 O ®<br />

For fixing pipework to lightweight<br />

blockwork the HX65 Pipe Clip<br />

Cable Type is not suitable for fixing<br />

directly to such walls because of the<br />

low pull-out resistance of the nail.<br />

In such circumstances a more<br />

secure hold can be achieved by<br />

fixing wooden dowels at each clip<br />

position. The dowels should be the<br />

solid type with a serrated surface<br />

and of sufficient size (not less than<br />

M8 x 30mm).<br />

Holes should first be drilled in the<br />

blockwork using a drill bit size<br />

which provides a tight fitting hole<br />

for the dowel, taking care not to<br />

over-drill the hole depth. After<br />

tapping in the dowels the pipe clips<br />

can then be fixed by knocking the<br />

nail into the centre of each dowel.<br />

Alternatively, use the screw fixed<br />

Fitting Clip HX84 shown below.<br />

The pipe is looped through the Back Box<br />

(HX109 or HX110).<br />

Completed installation.<br />

Two 5mm fixing<br />

holes, one each<br />

side<br />

80