KR QUANTEC ultra - KUKA Robotics

KR QUANTEC ultra - KUKA Robotics

KR QUANTEC ultra - KUKA Robotics

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>KR</strong> <strong>QUANTEC</strong> <strong>ultra</strong><br />

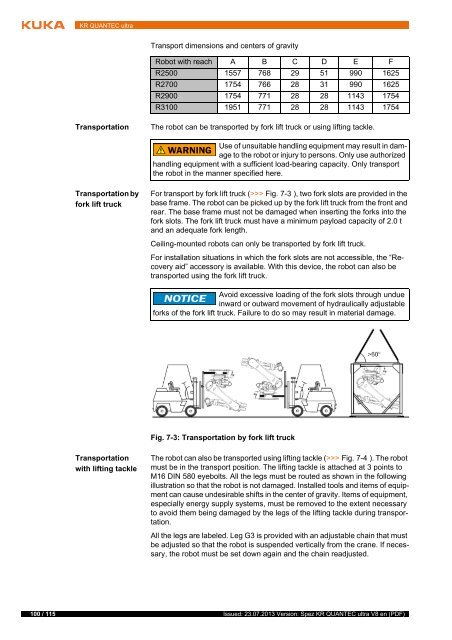

Transport dimensions and centers of gravity<br />

Robot with reach A B C D E F<br />

R2500 1557 768 29 51 990 1625<br />

R2700 1754 766 28 31 990 1625<br />

R2900 1754 771 28 28 1143 1754<br />

R3100 1951 771 28 28 1143 1754<br />

Transportation<br />

The robot can be transported by fork lift truck or using lifting tackle.<br />

Use of unsuitable handling equipment may result in damage<br />

to the robot or injury to persons. Only use authorized<br />

handling equipment with a sufficient load-bearing capacity. Only transport<br />

the robot in the manner specified here.<br />

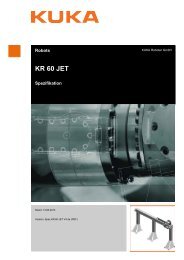

Transportation by<br />

fork lift truck<br />

For transport by fork lift truck (>>> Fig. 7-3 ), two fork slots are provided in the<br />

base frame. The robot can be picked up by the fork lift truck from the front and<br />

rear. The base frame must not be damaged when inserting the forks into the<br />

fork slots. The fork lift truck must have a minimum payload capacity of 2.0 t<br />

and an adequate fork length.<br />

Ceiling-mounted robots can only be transported by fork lift truck.<br />

For installation situations in which the fork slots are not accessible, the “Recovery<br />

aid” accessory is available. With this device, the robot can also be<br />

transported using the fork lift truck.<br />

Avoid excessive loading of the fork slots through undue<br />

inward or outward movement of hydraulically adjustable<br />

forks of the fork lift truck. Failure to do so may result in material damage.<br />

Fig. 7-3: Transportation by fork lift truck<br />

Transportation<br />

with lifting tackle<br />

The robot can also be transported using lifting tackle (>>> Fig. 7-4 ). The robot<br />

must be in the transport position. The lifting tackle is attached at 3 points to<br />

M16 DIN 580 eyebolts. All the legs must be routed as shown in the following<br />

illustration so that the robot is not damaged. Installed tools and items of equipment<br />

can cause undesirable shifts in the center of gravity. Items of equipment,<br />

especially energy supply systems, must be removed to the extent necessary<br />

to avoid them being damaged by the legs of the lifting tackle during transportation.<br />

All the legs are labeled. Leg G3 is provided with an adjustable chain that must<br />

be adjusted so that the robot is suspended vertically from the crane. If necessary,<br />

the robot must be set down again and the chain readjusted.<br />

100 / 115 Issued: 23.07.2013 Version: Spez <strong>KR</strong> <strong>QUANTEC</strong> <strong>ultra</strong> V8 en (PDF)