KR QUANTEC ultra - KUKA Robotics

KR QUANTEC ultra - KUKA Robotics

KR QUANTEC ultra - KUKA Robotics

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>KR</strong> <strong>QUANTEC</strong> <strong>ultra</strong><br />

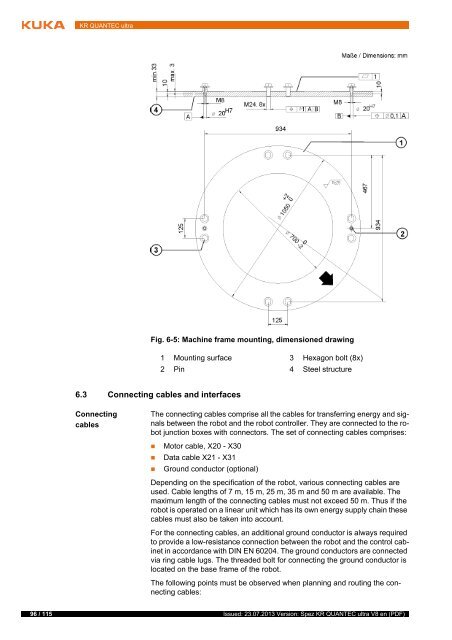

Fig. 6-5: Machine frame mounting, dimensioned drawing<br />

1 Mounting surface 3 Hexagon bolt (8x)<br />

2 Pin 4 Steel structure<br />

6.3 Connecting cables and interfaces<br />

Connecting<br />

cables<br />

The connecting cables comprise all the cables for transferring energy and signals<br />

between the robot and the robot controller. They are connected to the robot<br />

junction boxes with connectors. The set of connecting cables comprises:<br />

• Motor cable, X20 - X30<br />

• Data cable X21 - X31<br />

• Ground conductor (optional)<br />

Depending on the specification of the robot, various connecting cables are<br />

used. Cable lengths of 7 m, 15 m, 25 m, 35 m and 50 m are available. The<br />

maximum length of the connecting cables must not exceed 50 m. Thus if the<br />

robot is operated on a linear unit which has its own energy supply chain these<br />

cables must also be taken into account.<br />

For the connecting cables, an additional ground conductor is always required<br />

to provide a low-resistance connection between the robot and the control cabinet<br />

in accordance with DIN EN 60204. The ground conductors are connected<br />

via ring cable lugs. The threaded bolt for connecting the ground conductor is<br />

located on the base frame of the robot.<br />

The following points must be observed when planning and routing the connecting<br />

cables:<br />

96 / 115 Issued: 23.07.2013 Version: Spez <strong>KR</strong> <strong>QUANTEC</strong> <strong>ultra</strong> V8 en (PDF)