report

report

report

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

their production structures, as well as improving<br />

procurement processes. The following table provides<br />

details of where Charles Vögele’s products<br />

originate from:<br />

member of bSCi and Sai<br />

Charles Vögele Group has been a member of the<br />

non-governmental organization (NGO) Social<br />

Accountability International (SAI) since 2001. SAI<br />

promotes better social and working conditions<br />

within transnational companies. In 2004 Charles<br />

Vögele became one of the founding members of<br />

the Business Social Compliance Initiative (BSCI) in<br />

an effort to intensify work on improving compliance<br />

with social and environmental guidelines (e.g.<br />

on freedom of assembly, non-discrimination,<br />

wages, working hours) in the global supply chain.<br />

The standard BSCI Code of Conduct is now a fixed<br />

component of all Charles Vögele supplier contracts.<br />

This Code is based on numerous agreements,<br />

including the conventions of the International<br />

Labour Organization (ILO), the UN Global Compact<br />

and OECD guidelines.<br />

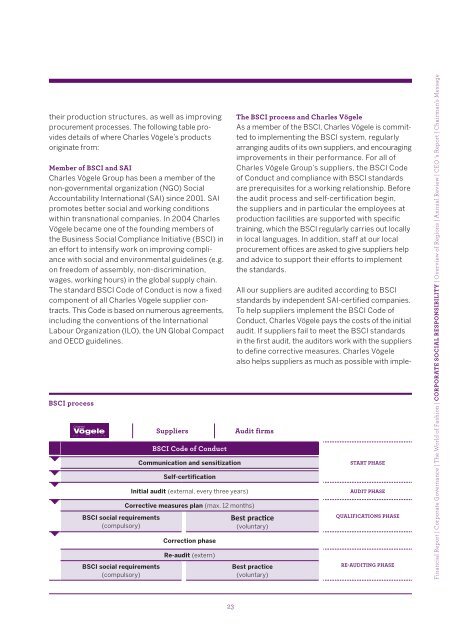

bSCi process<br />

BSCI social requirements<br />

(compulsory)<br />

BSCI social requirements<br />

(compulsory)<br />

Suppliers audit firms<br />

bSCi Code of Conduct<br />

23<br />

the bSCi process and Charles Vögele<br />

As a member of the BSCI, Charles Vögele is committed<br />

to implementing the BSCI system, regularly<br />

arranging audits of its own suppliers, and encouraging<br />

improvements in their performance. For all of<br />

Charles Vögele Group’s suppliers, the BSCI Code<br />

of Conduct and compliance with BSCI standards<br />

are prerequisites for a working relationship. Before<br />

the audit process and self-certification begin,<br />

the suppliers and in particular the employees at<br />

production facilities are supported with specific<br />

training, which the BSCI regularly carries out locally<br />

in local languages. In addition, staff at our local<br />

procurement offices are asked to give suppliers help<br />

and advice to support their efforts to implement<br />

the standards.<br />

All our suppliers are audited according to BSCI<br />

standards by independent SAI-certified companies.<br />

To help suppliers implement the BSCI Code of<br />

Conduct, Charles Vögele pays the costs of the initial<br />

audit. If suppliers fail to meet the BSCI standards<br />

in the first audit, the auditors work with the suppliers<br />

to define corrective measures. Charles Vögele<br />

also helps suppliers as much as possible with imple-<br />

Communication and sensitization Start pHaSe<br />

Self-certification<br />

Initial audit (external, every three years) auDit pHaSe<br />

Corrective measures plan (max. 12 months)<br />

Correction phase<br />

Re-audit (extern)<br />

Best practice<br />

(voluntary)<br />

Best practice<br />

(voluntary)<br />

QualifiCationS pHaSe<br />

re-auDitinG pHaSe<br />

Financial Report | Corporate Governance | The World of Fashion | Corporate SoCial reSponSibility | Overview of Regions | Annual Review | CEO 's Report | Chairman's Message