Fortification of Vegetable oil and Sugar with Vitamin A in Uganda

Fortification of Vegetable oil and Sugar with Vitamin A in Uganda

Fortification of Vegetable oil and Sugar with Vitamin A in Uganda

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

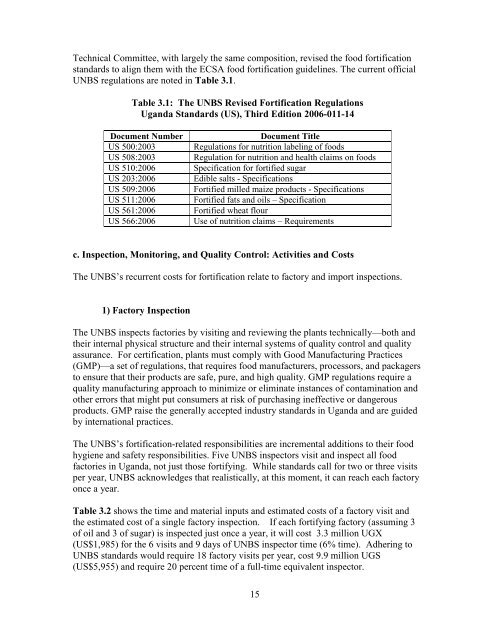

Technical Committee, <strong>with</strong> largely the same composition, revised the food fortification<br />

st<strong>and</strong>ards to align them <strong>with</strong> the ECSA food fortification guidel<strong>in</strong>es. The current <strong>of</strong>ficial<br />

UNBS regulations are noted <strong>in</strong> Table 3.1.<br />

Table 3.1: The UNBS Revised <strong>Fortification</strong> Regulations<br />

Ug<strong>and</strong>a St<strong>and</strong>ards (US), Third Edition 2006-011-14<br />

Document Number<br />

US 500:2003<br />

US 508:2003<br />

US 510:2006<br />

US 203:2006<br />

US 509:2006<br />

US 511:2006<br />

US 561:2006<br />

US 566:2006<br />

Document Title<br />

Regulations for nutrition label<strong>in</strong>g <strong>of</strong> foods<br />

Regulation for nutrition <strong>and</strong> health claims on foods<br />

Specification for fortified sugar<br />

Edible salts - Specifications<br />

Fortified milled maize products - Specifications<br />

Fortified fats <strong>and</strong> <strong>oil</strong>s – Specification<br />

Fortified wheat flour<br />

Use <strong>of</strong> nutrition claims – Requirements<br />

c. Inspection, Monitor<strong>in</strong>g, <strong>and</strong> Quality Control: Activities <strong>and</strong> Costs<br />

The UNBS’s recurrent costs for fortification relate to factory <strong>and</strong> import <strong>in</strong>spections.<br />

1) Factory Inspection<br />

The UNBS <strong>in</strong>spects factories by visit<strong>in</strong>g <strong>and</strong> review<strong>in</strong>g the plants technically—both <strong>and</strong><br />

their <strong>in</strong>ternal physical structure <strong>and</strong> their <strong>in</strong>ternal systems <strong>of</strong> quality control <strong>and</strong> quality<br />

assurance. For certification, plants must comply <strong>with</strong> Good Manufactur<strong>in</strong>g Practices<br />

(GMP)—a set <strong>of</strong> regulations, that requires food manufacturers, processors, <strong>and</strong> packagers<br />

to ensure that their products are safe, pure, <strong>and</strong> high quality. GMP regulations require a<br />

quality manufactur<strong>in</strong>g approach to m<strong>in</strong>imize or elim<strong>in</strong>ate <strong>in</strong>stances <strong>of</strong> contam<strong>in</strong>ation <strong>and</strong><br />

other errors that might put consumers at risk <strong>of</strong> purchas<strong>in</strong>g <strong>in</strong>effective or dangerous<br />

products. GMP raise the generally accepted <strong>in</strong>dustry st<strong>and</strong>ards <strong>in</strong> Ug<strong>and</strong>a <strong>and</strong> are guided<br />

by <strong>in</strong>ternational practices.<br />

The UNBS’s fortification-related responsibilities are <strong>in</strong>cremental additions to their food<br />

hygiene <strong>and</strong> safety responsibilities. Five UNBS <strong>in</strong>spectors visit <strong>and</strong> <strong>in</strong>spect all food<br />

factories <strong>in</strong> Ug<strong>and</strong>a, not just those fortify<strong>in</strong>g. While st<strong>and</strong>ards call for two or three visits<br />

per year, UNBS acknowledges that realistically, at this moment, it can reach each factory<br />

once a year.<br />

Table 3.2 shows the time <strong>and</strong> material <strong>in</strong>puts <strong>and</strong> estimated costs <strong>of</strong> a factory visit <strong>and</strong><br />

the estimated cost <strong>of</strong> a s<strong>in</strong>gle factory <strong>in</strong>spection. If each fortify<strong>in</strong>g factory (assum<strong>in</strong>g 3<br />

<strong>of</strong> <strong>oil</strong> <strong>and</strong> 3 <strong>of</strong> sugar) is <strong>in</strong>spected just once a year, it will cost 3.3 million UGX<br />

(US$1,985) for the 6 visits <strong>and</strong> 9 days <strong>of</strong> UNBS <strong>in</strong>spector time (6% time). Adher<strong>in</strong>g to<br />

UNBS st<strong>and</strong>ards would require 18 factory visits per year, cost 9.9 million UGS<br />

(US$5,955) <strong>and</strong> require 20 percent time <strong>of</strong> a full-time equivalent <strong>in</strong>spector.<br />

15