Fortification of Vegetable oil and Sugar with Vitamin A in Uganda

Fortification of Vegetable oil and Sugar with Vitamin A in Uganda

Fortification of Vegetable oil and Sugar with Vitamin A in Uganda

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

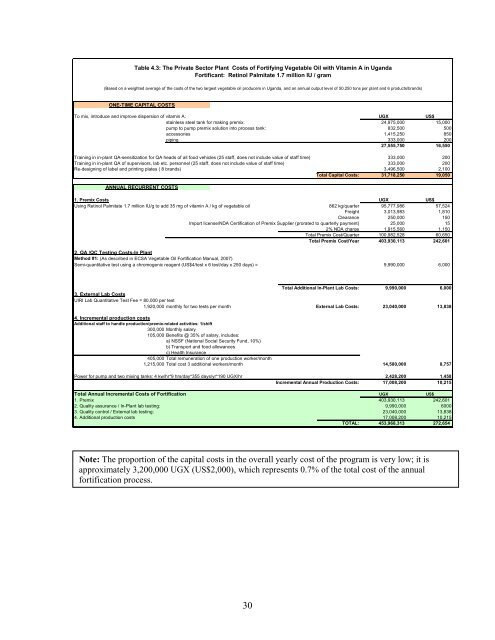

Table 4.3: The Private Sector Plant Costs <strong>of</strong> Fortify<strong>in</strong>g <strong>Vegetable</strong> Oil <strong>with</strong> <strong>Vitam<strong>in</strong></strong> A <strong>in</strong> Ug<strong>and</strong>a<br />

Fortificant: Ret<strong>in</strong>ol Palmitate 1.7 million IU / gram<br />

(Based on a weighted average <strong>of</strong> the costs <strong>of</strong> the two largest vegetable <strong>oil</strong> producers <strong>in</strong> Ug<strong>and</strong>a, <strong>and</strong> an annual output level <strong>of</strong> 50,250 tons per plant <strong>and</strong> 6 products/br<strong>and</strong>s)<br />

ONE-TIME CAPITAL COSTS<br />

To mix, <strong>in</strong>troduce <strong>and</strong> improve dispersion <strong>of</strong> vitam<strong>in</strong> A: UGX US$<br />

sta<strong>in</strong>less steel tank for mak<strong>in</strong>g premix: 24,975,000 15,000<br />

pump to pump premix solution <strong>in</strong>to process tank: 832,500 500<br />

accessories 1,415,250 850<br />

pip<strong>in</strong>g 333,000 200<br />

27,555,750 16,550<br />

Tra<strong>in</strong><strong>in</strong>g <strong>in</strong> <strong>in</strong>-plant QA-sensitization for QA heads <strong>of</strong> all food vehicles (25 staff, does not <strong>in</strong>clude value <strong>of</strong> staff time) 333,000 200<br />

Tra<strong>in</strong><strong>in</strong>g <strong>in</strong> <strong>in</strong>-plant QA <strong>of</strong> supervisors, lab etc. personnel (25 staff, does not <strong>in</strong>clude value <strong>of</strong> staff time) 333,000 200<br />

Re-design<strong>in</strong>g <strong>of</strong> label <strong>and</strong> pr<strong>in</strong>t<strong>in</strong>g plates ( 8 br<strong>and</strong>s) 3,496,500 2,100<br />

Total Capital Costs: 31,718,250 19,050<br />

ANNUAL RECURRENT COSTS<br />

1. Premix Costs UGX US$<br />

Us<strong>in</strong>g Ret<strong>in</strong>ol Palmitate 1.7 million IU/g to add 35 mg <strong>of</strong> vitam<strong>in</strong> A / kg <strong>of</strong> vegetable <strong>oil</strong> 862 kg/quarter 95,777,986 57,524<br />

Freight 3,013,983 1,810<br />

Clearance 250,000 150<br />

Import license/NDA Certification <strong>of</strong> Premix Supplier (prorated to quarterly payment) 25,000 15<br />

2% NDA charge 1,915,560 1,150<br />

Total Premix Cost/Quarter 100,982,528 60,650<br />

Total Premix Cost/Year 403,930,113 242,601<br />

2. QA /QC Test<strong>in</strong>g Costs-In Plant<br />

Method #1: (As described <strong>in</strong> ECSA <strong>Vegetable</strong> Oil <strong>Fortification</strong> Manual, 2007)<br />

Semi-quantitative test us<strong>in</strong>g a chromogenic reagent (US$4/test x 6 test/day x 250 days) = 9,990,000 6,000<br />

Total Additional In-Plant Lab Costs: 9,990,000 6,000<br />

3. External Lab Costs<br />

UIRI Lab Quantitative Test Fee = 80,000 per test<br />

1,920,000 monthly for two tests per month External Lab Costs: 23,040,000 13,838<br />

4. Incremental production costs<br />

Additional staff to h<strong>and</strong>le production/premix-related activities: 1/shift<br />

300,000 Monthly salary<br />

105,000 Benefits @ 35% <strong>of</strong> salary, <strong>in</strong>cludes:<br />

a) NSSF (National Social Security Fund, 10%)<br />

b) Transport <strong>and</strong> food allowances<br />

c) Health Insurance<br />

405,000 Total remuneration <strong>of</strong> one production worker/month<br />

1,215,000 Total cost 3 additional workers/month 14,580,000 8,757<br />

Power for pump <strong>and</strong> two mix<strong>in</strong>g tanks: 4 kw/hr*9 hrs/day*355 days/yr*190 UGX/hr 2,428,200 1,458<br />

Incremental Annual Production Costs: 17,008,200 10,215<br />

Total Annual Incremental Costs <strong>of</strong> <strong>Fortification</strong> UGX US$<br />

1. Premix 403,930,113 242,601<br />

2. Quality assurance / In-Plant lab test<strong>in</strong>g: 9,990,000 6000<br />

3. Quality control / External lab test<strong>in</strong>g: 23,040,000 13,838<br />

4. Additional production costs 17,008,200 10,215<br />

TOTAL: 453,968,313 272,654<br />

Note: The proportion <strong>of</strong> the capital costs <strong>in</strong> the overall yearly cost <strong>of</strong> the program is very low; it is<br />

approximately 3,200,000 UGX (US$2,000), which represents 0.7% <strong>of</strong> the total cost <strong>of</strong> the annual<br />

fortification process.<br />

30