MICHELIN - 2008 ANNUAL REPORT

MICHELIN - 2008 ANNUAL REPORT

MICHELIN - 2008 ANNUAL REPORT

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Energy savings<br />

and reduced emissions<br />

The environmental impact of tire building is limited and Michelin is committed<br />

to reduce this further. The Group developed internal standards, applied in all<br />

the countries where it operates, to monitor the environmental performance<br />

of its industrial sites.<br />

More than 80% of the raw materials<br />

purchased by the Group originate<br />

from ISO 14001 certified production<br />

sites. Michelin’s Environmental Management<br />

System (MEMS) is operational in 94% of its sites<br />

acquired more than five years ago (rubber tree<br />

plantations, R&D and production) and is being<br />

deployed in the logistics centers.<br />

Achieve 30% environmental<br />

footprint reduction<br />

The MEF, Michelin sites Environmental<br />

Footprint performance indicator, has been<br />

integrated into the Group’s scorecard and is<br />

reported on quarterly. MEF integrates water<br />

and energy consumption, carbon dioxide<br />

(CO 2 ), volatile organic compound (VOC) emissions<br />

and the generation of waste and its<br />

disposal in landfills by metric ton of finished<br />

product.<br />

In <strong>2008</strong>, the initial objective MEF of -20% by<br />

2011 versus 2005 was raised to -30% by 2013<br />

versus 2005.<br />

Stringent Environmental<br />

Management<br />

In <strong>2008</strong>, MEF was reduced by 21.4% versus<br />

2005. 77 sites were subjected to an energy<br />

audit and drew up an action plan. Each site<br />

identifies the locally available and cost-effective<br />

sources of renewable energy. The deployment<br />

of solvent-free manufacturing processes<br />

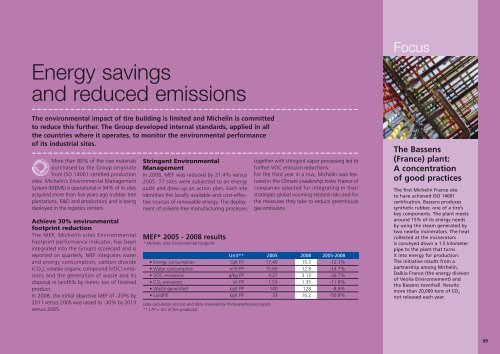

MEF* 2005 - <strong>2008</strong> results<br />

* Michelin sites Environmental Footprint.<br />

together with stringent vapor processing led to<br />

further VOC emission reductions.<br />

For the third year in a row, Michelin was featured<br />

in the Climate Leadership Index France of<br />

companies selected for integrating in their<br />

strategies global warming-related risks and for<br />

the measures they take to reduce greenhouse<br />

gas emissions.<br />

Unit** 2005 <strong>2008</strong> 2005-<strong>2008</strong><br />

• Energy consumption Gj/t PP 17.40 15.3 -12.1%<br />

• Water consumption m 3 /t PP 15.00 12.8 -14.7%<br />

• VOC emissions g/kg PP 4.27 3.13 -26.7%<br />

• CO 2 emissions t/t PP 1.53 1.35 -11.8%<br />

• Waste generated kg/t PP 140 128 -8.9%<br />

• Landfill kg/t PP 33 16.2 -50.9%<br />

Data calculation process and data reviewed by PricewaterhouseCoopers.<br />

** t PP = ton of tire produced.<br />

Focus<br />

The Bassens<br />

(France) plant:<br />

A concentration<br />

of good practices<br />

The first Michelin France site<br />

to have achieved ISO 14001<br />

certification, Bassens produces<br />

synthetic rubber, one of a tire’s<br />

key components. The plant meets<br />

around 15% of its energy needs<br />

by using the steam generated by<br />

two nearby incinerators. The heat<br />

collected at the incinerators<br />

is conveyed down a 1.5 kilometer<br />

pipe to the plant that turns<br />

it into energy for production.<br />

The initiative results from a<br />

partnership among Michelin,<br />

Dalkia France (the energy division<br />

of Veolia Environnement) and<br />

the Bassens townhall. Results:<br />

more than 20,000 tons of CO 2<br />

not released each year.<br />

09