MICHELIN - 2008 ANNUAL REPORT

MICHELIN - 2008 ANNUAL REPORT

MICHELIN - 2008 ANNUAL REPORT

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Risk Management<br />

Operating Risk Management<br />

Michelin relies on three tiers of independent and highly responsible<br />

groups to guarantee the robustness of its risk control policy:<br />

● Operating managers identify and manage risks in their respective<br />

entities (prevention, protection and business continuation plan) in<br />

line with Group standards.<br />

● Group Services (Finance, Legal, Environment & Prevention…):<br />

analyze risks, define prevention and protection standards,<br />

manage and monitor implementation of risk policy in their own<br />

field of expertise.<br />

● Internal auditors: review overall risk control measures.<br />

Michelin’s risk policy is defined, supervised and coordinated by<br />

the Group’s Risk Manager.<br />

The Group’s Risk Committee meets 3 times per year to review a<br />

number of risk control measures, in order, more specifically, to<br />

support the Managing Partners in their risk control decisions with<br />

special emphasis on potentially serious risk.<br />

Financial Risk<br />

Financial risk is dealt with in Note 4 of the Consolidated Financial<br />

Statements, on page 95 of this Report.<br />

Industrial Hazards<br />

Industrial hazard control is vital for the continuation of Michelin’s<br />

operations over the long term while ensuring the protection of its<br />

personnel, its assets and its environment.<br />

Michelin’s industrial risk map is updated at least once a year. This<br />

helps to identify Group risks and assess their criticality. Prioritized<br />

multi-annual action plans with a strong emphasis on prevention<br />

are drawn up and implemented in the annual plans. They address<br />

in particular the issues of safety at the workplace, industrial<br />

hygiene, and asset and environmental protection.<br />

Monitoring of the Group’s progress in the areas of Environment<br />

and Prevention (EP) is based on:<br />

● 5-year orientations and objectives, which are revised each year<br />

based on the evolution of the assessments that are carried out.<br />

Such orientations and objectives are given concrete expression in<br />

progress plans and investment plans for each operating entity.<br />

● a network of experts who are based in each site and bring<br />

technical and methodological support to the local site managers.<br />

The latter bear ultimate responsibility for the performance of their<br />

entity’s Environmental and Prevention performance.<br />

The robustness of the approach is based on implementation<br />

of an Environmental and Risk Prevention Management System<br />

(SMEP). This is an extension to all other EP fields (Asset Protection,<br />

Work Safety, Industrial Hygiene, Ergonomics) of the existing<br />

Environmental Management System.<br />

The system is being rolled out in the industrial sites. Michelin<br />

teams have been auditing sites since 2005 and 2006. The system<br />

will be fully deployed by 2011.<br />

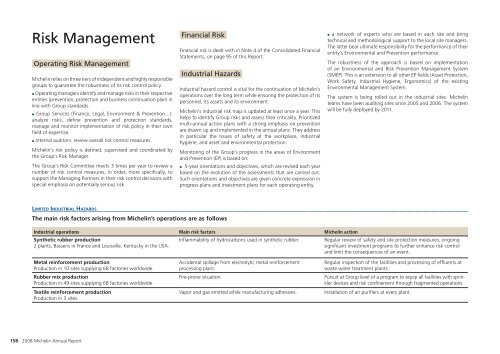

LIMITED INDUSTRIAL HAZARDS<br />

The main risk factors arising from Michelin’s operations are as follows<br />

Industrial operations Main risk factors Michelin action<br />

Synthetic rubber production<br />

2 plants, Bassens in France and Louisville, Kentucky in the USA.<br />

Inflammability of hydrocarbons used in synthetic rubber. Regular review of safety and site protection measures; ongoing<br />

significant investment programs to further enhance risk control<br />

and limit the consequences of an event.<br />

Metal reinforcement production<br />

Production in 10 sites supplying 68 factories worldwide.<br />

Rubber mix production<br />

Production in 49 sites supplying 68 factories worldwide.<br />

Textile reinforcement production<br />

Production in 3 sites.<br />

Accidental spillage from electrolytic metal reinforcement<br />

processing plant.<br />

Fire-prone situation.<br />

Vapor and gas emitted while manufacturing adhesives.<br />

Regular inspection of the facilities and processing of effluents at<br />

waste water treatment plants.<br />

Pursuit at Group level of a program to equip all facilities with sprinkler<br />

devices and risk confinement through fragmented operations.<br />

Installation of air purifiers at every plant.<br />

158 <strong>2008</strong> Michelin Annual Report