MICHELIN - 2008 ANNUAL REPORT

MICHELIN - 2008 ANNUAL REPORT

MICHELIN - 2008 ANNUAL REPORT

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

As of the end of <strong>2008</strong>, the Group manufactures 99.5% of its tires<br />

at sites certified ISO 14001. The Group’s two rubber plantations,<br />

the main sites of the Technology Center and all the semi-finished<br />

products facilities were also certified. Although MEMS is not a<br />

preriquisite for ISO 140001 certification, it has clearly helped<br />

achieve it.<br />

2.8.2 Environmental Governance and Internal<br />

Organization<br />

To guarantee the robustness of risk analysis and the relevance<br />

of the solutions that are adopted, Michelin Group has adopted<br />

a network structure to respond to its environment, hygiene,<br />

workplace safety and industrial hazard prevention issues.<br />

The Group’s Environment and Prevention network comprises a<br />

hundred or so experts who operate in different countries and<br />

Product Lines, in addition to a dedicated team in each site. The<br />

head of the Environment and Prevention network reports to the<br />

Group’s Executive Council and manages a dedicated budget.<br />

An improvement objective is defined each year in the Annual Plan<br />

through the MEF indicator (see above). The Group raised its MEF<br />

target from -20% in 2011 to -30% at the end of 2013. The regular<br />

deployment of this objective in all Group operations ensures that<br />

realistic targets are set. Progress in the MEF is reviewed quarterly<br />

by the Prevention and Industrial Performance Department and is<br />

part of the Group’s scorecard.<br />

2.8.3 Employee training and information<br />

MEMS deployment and specific training has raised environmental<br />

awareness on the part of the 88,000 or so employees of Michelin’s<br />

certified sites. The training courses, which are tailored to each<br />

type of workstation, cover the main impact factors specific to site<br />

operations. In addition, employees benefit from regular refresher<br />

courses.<br />

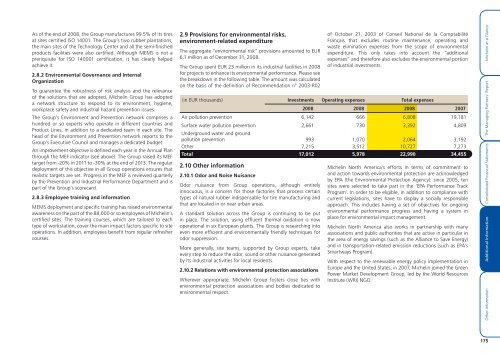

2.9 Provisions for environmental risks,<br />

environment-related expenditure<br />

The aggregate “environmental risk” provisions amounted to EUR<br />

6.1 million as of December 31, <strong>2008</strong>.<br />

The Group spent EUR 23 million in its industrial facilities in <strong>2008</strong><br />

for projects to enhance its environmental performance. Please see<br />

the breakdown in the following table. The amount was calculated<br />

on the basis of the definition of Recommendation n° 2003-R02<br />

of October 21, 2003 of Conseil National de la Comptabilité<br />

Français that excludes routine maintenance, operating and<br />

waste elimination expenses from the scope of environmental<br />

expenditure. This only takes into account the “additional<br />

expenses” and therefore also excludes the environmental portion<br />

of industrial investments.<br />

(in EUR thousands) Investments Operating expenses Total expenses<br />

<strong>2008</strong> <strong>2008</strong> <strong>2008</strong> 2007<br />

Air pollution prevention 6,142 666 6,808 19,181<br />

Surface water pollution prevention 2,661 730 3,392 4,809<br />

Underground water and ground<br />

pollution prevention 993 1,070 2,064 3,192<br />

Other 7,215 3,512 10,727 7,273<br />

Total 17,012 5,978 22,990 34,455<br />

2.10 Other information<br />

2.10.1 Odor and Noise Nuisance<br />

Odor nuisance from Group operations, although entirely<br />

innocuous, is a concern for those factories that process certain<br />

types of natural rubber indispensable for tire manufacturing and<br />

that are located in or near urban areas.<br />

A standard solution across the Group is continuing to be put<br />

in place. The solution, using effluent thermal oxidation is now<br />

operational in six European plants. The Group is researching into<br />

even more efficient and environmentally friendly techniques for<br />

odor suppression.<br />

More generally, site teams, supported by Group experts, take<br />

every step to reduce the odor, sound or other nuisance generated<br />

by its industrial activities for local residents.<br />

2.10.2 Relations with environmental protection associations<br />

Wherever appropriate, Michelin Group fosters close ties with<br />

environmental protection associations and bodies dedicated to<br />

environmental respect.<br />

Michelin North America’s efforts in terms of commitment to<br />

and action towards environmental protection are acknowledged<br />

by EPA (the Environmental Protection Agency): since 2005, ten<br />

sites were selected to take part in the ‘EPA Performance Track<br />

Program’. In order to be eligible, in addition to compliance with<br />

current legislations, sites have to display a socially responsible<br />

approach. This includes having a set of objectives for ongoing<br />

environmental performance progress and having a system in<br />

place for environmental impact management.<br />

Michelin North America also works in partnership with many<br />

associations and public authorities that are active in particular in<br />

the area of energy savings (such as the Alliance to Save Energy)<br />

and in transportation-related emission reductions (such as EPA’s<br />

Smartways Program).<br />

With respect to the renewable energy policy implementation in<br />

Europe and the United States, in 2007, Michelin joined the Green<br />

Power Market Development Group, led by the World Resources<br />

Institute (WRI) NGO.<br />

Other Information<br />

Additional Information Consolidated Financial Statements The Managing Partners’ Report Michelin at a Glance<br />

175