201303.pdf 36567KB Mar 22 2013 09:11:22 PM

201303.pdf 36567KB Mar 22 2013 09:11:22 PM

201303.pdf 36567KB Mar 22 2013 09:11:22 PM

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Cree<br />

Cree is in a unique position in the<br />

industry in that it uses a GaN process<br />

for its RF devices and an SiC process<br />

for its power devices. Due to its in-depth<br />

knowledge and use of both processes,<br />

the company has made a conscious decision<br />

to use SiC for high voltages.<br />

Cree’s target market for SiC power<br />

devices is 1200V and 1700V solutions,<br />

with 600V coming later. At higher<br />

voltages, SiC unipolar devices have<br />

an advantage over bipolar Si. The<br />

challenge at 600V is that Si has better<br />

performance, while Si CoolMOS<br />

and insulated-gate bipolar transistors<br />

(IGBTs) are lower cost.<br />

The primary advantage of SiC<br />

MOSFETs is their very low switching<br />

losses, which increase efficiency and<br />

enable higher-frequency operation. In<br />

addition, the SiC MOSFET’s positive<br />

temperature coefficient allows easy<br />

paralleling to obtain higher operating<br />

currents.<br />

SiC has been successfully tested<br />

at 10-kV levels. Cree targets future<br />

MOSFETs at around the 3.3- and 6.5-<br />

LikE This?<br />

For more articles like this one,<br />

go to www.edn.com/design/<br />

power-management.<br />

kV levels and at 10 kV. IGBTs have that<br />

market now, but SiC’s low switching<br />

losses would provide significant performance<br />

advantages. Even at frequencies<br />

below 4 kHz, SiC MOSFETs substantially<br />

reduce losses compared with<br />

IGBTs at these voltages.<br />

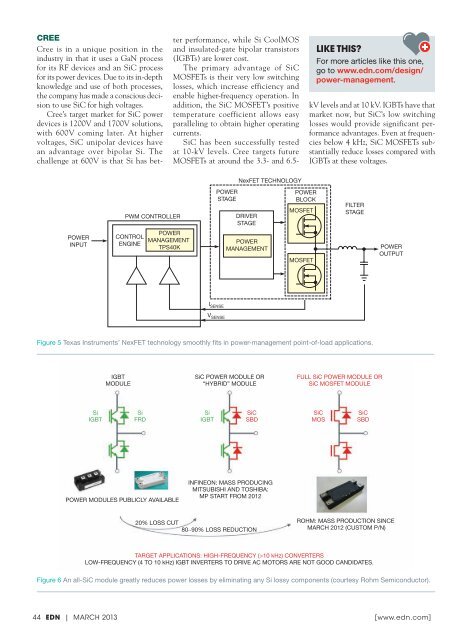

NexFET TECHNOLOGY<br />

POWER<br />

INPUT<br />

PWM CONTROLLER<br />

CONTROL<br />

ENGINE<br />

POWER<br />

MANAGEMENT<br />

TPS40K<br />

POWER<br />

STAGE<br />

DRIVER<br />

STAGE<br />

POWER<br />

MANAGEMENT<br />

POWER<br />

BLOCK<br />

MOSFET<br />

MOSFET<br />

FILTER<br />

STAGE<br />

POWER<br />

OUTPUT<br />

I SENSE<br />

V SENSE<br />

Figure 5 Texas Instruments’ NexFET technology smoothly fits in power-management point-of-load applications.<br />

IGBT<br />

MODULE<br />

SiC POWER MODULE OR<br />

“HYBRID” MODULE<br />

FULL SiC POWER MODULE OR<br />

SiC MOSFET MODULE<br />

Si<br />

IGBT<br />

Si<br />

FRD<br />

Si<br />

IGBT<br />

SiC<br />

SBD<br />

SiC<br />

MOS<br />

SiC<br />

SBD<br />

POWER MODULES PUBLICLY AVAILABLE<br />

INFINEON: MASS PRODUCING<br />

MITSUBISHI AND TOSHIBA:<br />

MP START FROM 2012<br />

EDN1303CS Fig 8.eps<br />

20% LOSS CUT<br />

80∼90% LOSS REDUCTION<br />

DIANE<br />

ROHM: MASS PRODUCTION SINCE<br />

MARCH 2012 (CUSTOM P/N)<br />

TARGET APPLICATIONS: HIGH-FREQUENCY (>10 kHz) CONVERTERS<br />

LOW-FREQUENCY (4 TO 10 kHz) IGBT INVERTERS TO DRIVE AC MOTORS ARE NOT GOOD CANDIDATES.<br />

Figure 6 An all-SiC module greatly reduces power losses by eliminating any Si lossy components (courtesy Rohm Semiconductor).<br />

44 EDN | <strong>Mar</strong>ch <strong>2013</strong> [ www.edn.com ]

![[270].pdf 37407KB Sep 02 2010 09:55:57 AM - ElectronicsAndBooks](https://img.yumpu.com/50350834/1/185x260/270pdf-37407kb-sep-02-2010-095557-am-electronicsandbooks.jpg?quality=85)

![draaien, A Viruly 1935 OCR c20130324 [320]. - ElectronicsAndBooks](https://img.yumpu.com/49957773/1/190x252/draaien-a-viruly-1935-ocr-c20130324-320-electronicsandbooks.jpg?quality=85)

![20051110 c20051031 [105].pdf 35001KB Feb 18 2009 08:46:32 PM](https://img.yumpu.com/48687202/1/190x253/20051110-c20051031-105pdf-35001kb-feb-18-2009-084632-pm.jpg?quality=85)