201303.pdf 36567KB Mar 22 2013 09:11:22 PM

201303.pdf 36567KB Mar 22 2013 09:11:22 PM

201303.pdf 36567KB Mar 22 2013 09:11:22 PM

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

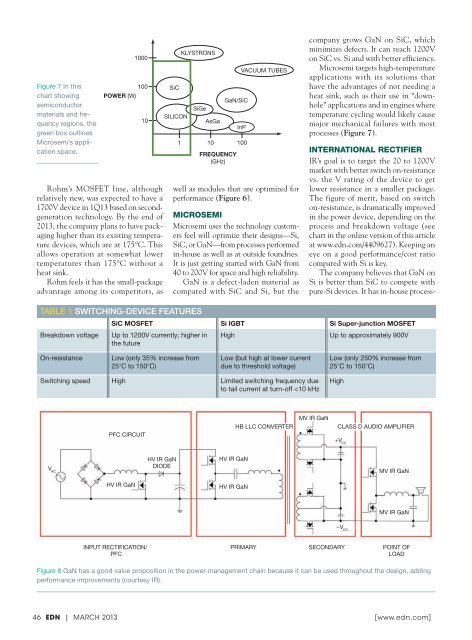

Figure 7 In this<br />

chart showing<br />

semiconductor<br />

materials and frequency<br />

regions, the<br />

green box outlines<br />

Microsemi’s application<br />

space.<br />

1000<br />

100<br />

POWER (W)<br />

10<br />

Rohm’s MOSFET line, although<br />

relatively new, was expected to have a<br />

1700V device in 1Q13 based on secondgeneration<br />

technology. By the end of<br />

<strong>2013</strong>, the company plans to have packaging<br />

higher than its existing temperature<br />

devices, which are at 175°C. This<br />

allows operation at somewhat lower<br />

temperatures than 175°C without a<br />

heat sink.<br />

Rohm feels it has the small-package<br />

advantage among its competitors, as<br />

SiC<br />

SILICON<br />

KLYSTRONS<br />

SiGe<br />

AsGa<br />

GaN/SiC<br />

VACUUM TUBES<br />

InP<br />

1 10 100<br />

FREQUENCY<br />

(GHz)<br />

well as modules that are optimized for<br />

performance (Figure 6).<br />

MicroseMi<br />

Microsemi uses the technology customers<br />

feel will optimize their designs—Si,<br />

SiC, or GaN—from processes performed<br />

in-house as well as at outside foundries.<br />

It is just getting started with GaN from<br />

EDN1303CS Fig 14.eps DIANE<br />

40 to 200V for space and high reliability.<br />

GaN is a defect-laden material as<br />

compared with SiC and Si, but the<br />

company grows GaN on SiC, which<br />

minimizes defects. It can reach 1200V<br />

on SiC vs. Si and with better efficiency.<br />

Microsemi targets high-temperature<br />

applications with its solutions that<br />

have the advantages of not needing a<br />

heat sink, such as their use in “downhole”<br />

applications and in engines where<br />

temperature cycling would likely cause<br />

major mechanical failures with most<br />

processes (Figure 7).<br />

international rectifier<br />

IR’s goal is to target the 20 to 1200V<br />

market with better switch on-resistance<br />

vs. the V rating of the device to get<br />

lower resistance in a smaller package.<br />

The figure of merit, based on switch<br />

on-resistance, is dramatically improved<br />

in the power device, depending on the<br />

process and breakdown voltage (see<br />

chart in the online version of this article<br />

at www.edn.com/44<strong>09</strong>627). Keeping an<br />

eye on a good performance/cost ratio<br />

compared with Si is key.<br />

The company believes that GaN on<br />

Si is better than SiC to compete with<br />

pure-Si devices. It has in-house process-<br />

Table 1 Switching-device featureS<br />

SiC MOSFET Si IGBT Si Super-junction MOSFET<br />

breakdown voltage Up to 1200V currently; higher in<br />

the future<br />

High<br />

Up to approximately 900V<br />

On-resistance<br />

low (only 35% increase from<br />

25°C to 150°C)<br />

low (but high at lower current<br />

due to threshold voltage)<br />

low (only 250% increase from<br />

25°C to 150°C)<br />

Switching speed High limited switching frequency due<br />

to tail current at turn-off

![[270].pdf 37407KB Sep 02 2010 09:55:57 AM - ElectronicsAndBooks](https://img.yumpu.com/50350834/1/185x260/270pdf-37407kb-sep-02-2010-095557-am-electronicsandbooks.jpg?quality=85)

![draaien, A Viruly 1935 OCR c20130324 [320]. - ElectronicsAndBooks](https://img.yumpu.com/49957773/1/190x252/draaien-a-viruly-1935-ocr-c20130324-320-electronicsandbooks.jpg?quality=85)

![20051110 c20051031 [105].pdf 35001KB Feb 18 2009 08:46:32 PM](https://img.yumpu.com/48687202/1/190x253/20051110-c20051031-105pdf-35001kb-feb-18-2009-084632-pm.jpg?quality=85)