Extraction Technologies For Medicinal And Aromatic Plants - Unido

Extraction Technologies For Medicinal And Aromatic Plants - Unido

Extraction Technologies For Medicinal And Aromatic Plants - Unido

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

10 SUPERCRITICAL FLUID EXTRACTION OF MEDICINAL AND AROMATIC PLANTS: FUNDAMENTALS AND APPLICATIONS<br />

To measure extraction profi les, a small pilot-scale apparatus can<br />

be used. Extractor and separator volumes do not need to exceed 1 liter each.<br />

The analytical system must be suitable to measure the concentration and purity<br />

of the products of interest. Basic requirements in terms of equipment are:<br />

1. A liquid CO2<br />

storage tank<br />

2. A pump for liquid CO2<br />

3. A cooler to prevent CO2<br />

from evaporating in the pump<br />

4. A heat exchanger to control the temperature of CO2<br />

entering<br />

the extractor<br />

5. An extraction vessel<br />

6. A heat exchanger to control the CO2<br />

plus solute mixture entering<br />

the separator<br />

7. A separation vessel<br />

Note that condensing and recycling of CO2 after separation is<br />

not needed at the laboratory-scale developmental level, whereas these are<br />

essential requirements at the industrial production level.<br />

All parts of the SFE laboratory-scale plant must be designed<br />

in order to resist the maximum operating pressure. If this does not exceed<br />

300-350 bar, the entire equipment (e.g. vessels, valves, fi ttings) is pretty<br />

much of standard type and relatively inexpensive. If, as usual, stainless<br />

steel is used, the thickness of any part of the plant can be easily calculated<br />

by applying the Von-Mises equation:<br />

with:<br />

Pi k2<br />

k2 √⎯3 < σam<br />

(5)<br />

– 1<br />

σam = σs<br />

Sf<br />

where Pi is the internal pressure, k is the external to internal diameter ratio,<br />

σs is the yield stress, and Sf is a suitable safety factor (usually Sf=1.5).<br />

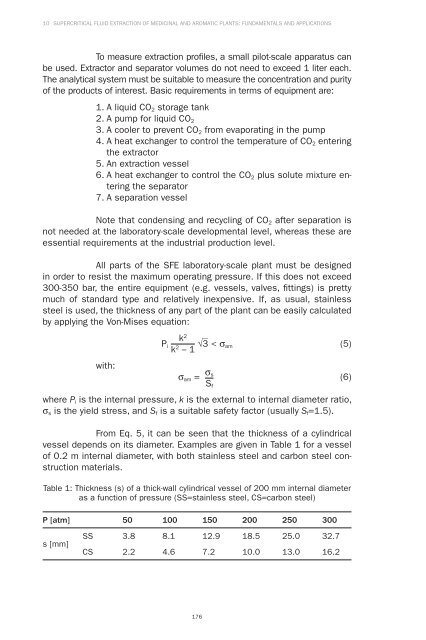

From Eq. 5, it can be seen that the thickness of a cylindrical<br />

vessel depends on its diameter. Examples are given in Table 1 for a vessel<br />

of 0.2 m internal diameter, with both stainless steel and carbon steel construction<br />

materials.<br />

Table 1: Thickness (s) of a thick-wall cylindrical vessel of 200 mm internal diameter<br />

as a function of pressure (SS=stainless steel, CS=carbon steel)<br />

P [atm] 50 100 150 200 250 300<br />

s [mm]<br />

SS 3.8 8.1 12.9 18.5 25.0 32.7<br />

CS 2.2 4.6 7.2 10.0 13.0 16.2<br />

176<br />

(6)