Extraction Technologies For Medicinal And Aromatic Plants - Unido

Extraction Technologies For Medicinal And Aromatic Plants - Unido

Extraction Technologies For Medicinal And Aromatic Plants - Unido

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

EXTRACTION TECHNOLOGIES FOR MEDICINAL AND AROMATIC PLANTS<br />

are inexpensive, easy to construct and suitable for fi eld operation. These<br />

are still widely used with portable equipment in many countries.<br />

The main disadvantage of water distillation is that complete<br />

extraction is not possible. Besides, certain esters are partly hydrolyzed and<br />

sensitive substances like aldehydes tend to polymerize. Water distillation<br />

requires a greater number of stills, more space and more fuel. It demands<br />

considerable experience and familiarity with the method. The high-boiling<br />

and somewhat water-soluble oil constituents cannot be completely vaporized<br />

or they require large quantities of steam. Thus, the process becomes<br />

uneconomical. <strong>For</strong> these reasons, water distillation is used only in cases in<br />

which the plant material by its very nature cannot be processed by water and<br />

steam distillation or by direct steam distillation.<br />

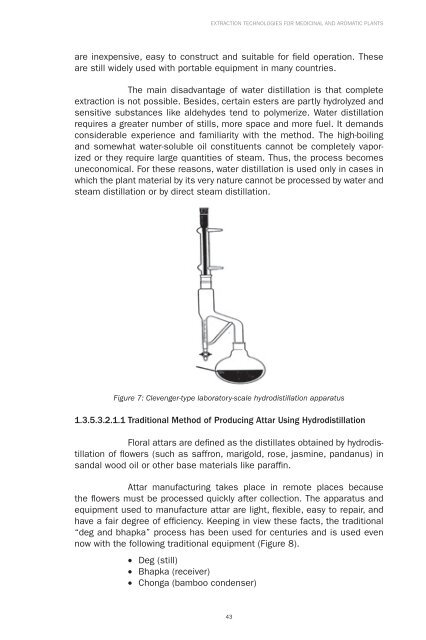

Figure 7: Clevenger-type laboratory-scale hydrodistillation apparatus<br />

1.3.5.3.2.1.1 Traditional Method of Producing Attar Using Hydrodistillation<br />

Floral attars are defi ned as the distillates obtained by hydrodistillation<br />

of fl owers (such as saffron, marigold, rose, jasmine, pandanus) in<br />

sandal wood oil or other base materials like paraffi n.<br />

Attar manufacturing takes place in remote places because<br />

the fl owers must be processed quickly after collection. The apparatus and<br />

equipment used to manufacture attar are light, fl exible, easy to repair, and<br />

have a fair degree of effi ciency. Keeping in view these facts, the traditional<br />

“deg and bhapka” process has been used for centuries and is used even<br />

now with the following traditional equipment (Figure 8).<br />

• Deg (still)<br />

• Bhapka (receiver)<br />

•<br />

Chonga (bamboo condenser)<br />

43