SOP â Malaria Microscopy - NVBDCP

SOP â Malaria Microscopy - NVBDCP

SOP â Malaria Microscopy - NVBDCP

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

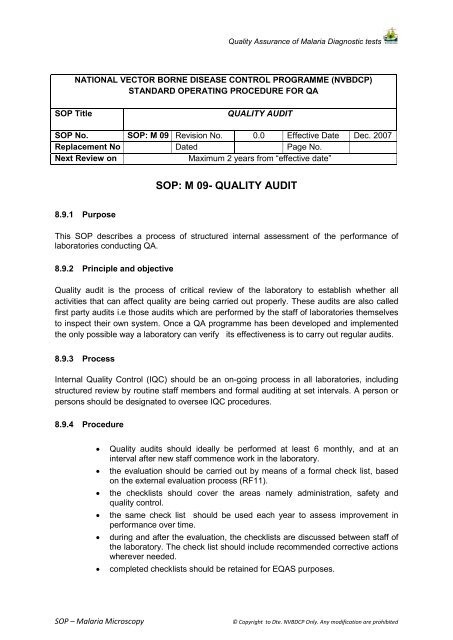

Quality Assurance of <strong>Malaria</strong> Diagnostic testsNATIONAL VECTOR BORNE DISEASE CONTROL PROGRAMME (<strong>NVBDCP</strong>)STANDARD OPERATING PROCEDURE FOR QA<strong>SOP</strong> TitleQUALITY AUDIT<strong>SOP</strong> No. <strong>SOP</strong>: M 09 Revision No. 0.0 Effective Date Dec. 2007Replacement No Dated Page No.Next Review onMaximum 2 years from “effective date”<strong>SOP</strong>: M 09- QUALITY AUDIT8.9.1 PurposeThis <strong>SOP</strong> describes a process of structured internal assessment of the performance oflaboratories conducting QA.8.9.2 Principle and objectiveQuality audit is the process of critical review of the laboratory to establish whether allactivities that can affect quality are being carried out properly. These audits are also calledfirst party audits i.e those audits which are performed by the staff of laboratories themselvesto inspect their own system. Once a QA programme has been developed and implementedthe only possible way a laboratory can verify its effectiveness is to carry out regular audits.8.9.3 ProcessInternal Quality Control (IQC) should be an on-going process in all laboratories, includingstructured review by routine staff members and formal auditing at set intervals. A person orpersons should be designated to oversee IQC procedures.8.9.4 Procedure• Quality audits should ideally be performed at least 6 monthly, and at aninterval after new staff commence work in the laboratory.• the evaluation should be carried out by means of a formal check list, basedon the external evaluation process (RF11).• the checklists should cover the areas namely administration, safety andquality control.• the same check list should be used each year to assess improvement inperformance over time.• during and after the evaluation, the checklists are discussed between staff ofthe laboratory. The check list should include recommended corrective actionswherever needed.• completed checklists should be retained for EQAS purposes.<strong>SOP</strong> – <strong>Malaria</strong> <strong>Microscopy</strong>© Copyright to Dte. <strong>NVBDCP</strong> Only. Any modification are prohibited