SIMATIC ET 200 - For distributed automation solutions - November ...

SIMATIC ET 200 - For distributed automation solutions - November ...

SIMATIC ET 200 - For distributed automation solutions - November ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

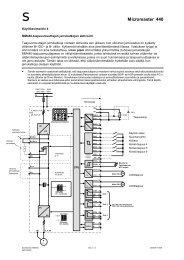

© Siemens AG 2010<strong>ET</strong> <strong>200</strong> – featuresSimple configuration and increased plant availabilitySimple configurationIntegral plug-in connections make installation quick and easyand therefore reduce the costs. In the case of modular systems,mounting is on a rail. The modules are snapped ontothe rail and plugged into each other.The sensors and actuators can be easily connected to a bussystem without the need to use an array of single wires withcable distributors and cable racks. This makes the wiring simpleand transparent, less error-prone and therefore low-cost.Self-assembling backplane busPermanent wiringDue to the separation of mechanics and electronics, permanentwiring is possible, i.e. the station can be prewired beforeinstallation or start-up. Prewiring can therefore be inspectedwithout the electronics modules which prevents damage tosensitive components. The start-up time is thereforereduced. In addition, the modules can also be replaced in theevent of a fault without time-consuming rewiring.Permanent wiring: connections and electronics are separate from oneanotherHot swappingIn the event of a fault, electronic modules are easily replacedduring operation with the equipment live (hot swapping).The station remains functional, and the plant therefore remainsavailable – there is no need for costly shutting downand starting up of the plant. While the components are beingreplaced, the wiring remains intact.Hot swapping: Module replacement during operationConfiguration in Run (CiR)Changes or expansions are required even during active operationof a (sub-) system. Possible applications are due to nonstoprequirements, that is, in continuous processes in processengineering that cannot be shut down or whose productioncannot be interrupted.Changes to the hardware configuration in RUN are possiblewhen <strong>distributed</strong> I/Os are connected to the S7-400:• Stations can be added and removed,e.g. for configuring a new process line• I/O modules can be added and removed,e.g. for implementing additional sensors• I/O modules can be reparameterized,e.g. for replacement partsChanges to the configuration are possible during normal operation22<strong>ET</strong> <strong>200</strong> – features