SIMATIC ET 200 - For distributed automation solutions - November ...

SIMATIC ET 200 - For distributed automation solutions - November ...

SIMATIC ET 200 - For distributed automation solutions - November ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

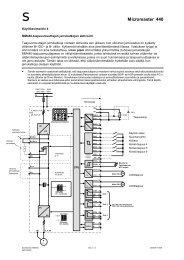

© Siemens AG 2010<strong>SIMATIC</strong> <strong>ET</strong> <strong>200</strong>ecoVeronesi, Italy –Animal feed manufacturer modernizes basic materialsinfeedRequirementsOne of the largest European manufacturers of animal feeds,Veronesi S.p.A, Italy, was looking for an efficient solution formodernized <strong>automation</strong> of their basic materials infeed. Materialsinfeed is the critical point in production for the animalfeed manufacturer. When no products continue to come in,the entire plant is idle. Thus it was important that productioncontinues without restriction. The safety regulations for installationsin a dust-filled atmosphere must also be satisfied.The greatest challenge, however, was presented by selectionof the technical configuration: All sensors and actuators hadto be connected to the <strong>distributed</strong> I/O over the shortest possibleconnections; this demanded a cabinet-free configuration.BenefitsCommissioning of the fully automated complete solution wasproblem-free and implementation was possible during normaloperation of the plant. The wiring over the ECOFAST connectionswas extremely easy, so the retrofit was completed quickly.The new solution supported a cost-saving bus architecturewith cabinet-free <strong>distributed</strong> I/O as well as increased transparencyin the <strong>automation</strong> system.Since the entire solution originates from Siemens, the trainingtime for the maintenance personnel was reduced. In the eventof a disturbance, they merely need to contact a partner at Siemens.SolutionThe Swiss system integrator ASE-Bühler AG developed thenew plant concept – taking into account the plant philosophyof Veronesi: All subsystems are subdivided into individual sectors.The materials infeed too. This was automated by meansof a <strong>SIMATIC</strong> S7-400 controller. It replaced the aging relay control.The special feature of the new plant is the PROFIBUS architecture.Four PROFIBUS lines run from the S7-400 PLC intothe concrete towers containing the silos. A total of 150<strong>SIMATIC</strong> <strong>ET</strong> <strong>200</strong>eco stations are connected to the four buslines which were installed without a cabinet directly in theplant. Control boxes were only required for the repeaters thatwere installed to support PROFIBUS branches. The connectionswere implemented using the standardized ECOFAST systemwith data and power supplied along the same cable.62References