SIMATIC ET 200 - For distributed automation solutions - November ...

SIMATIC ET 200 - For distributed automation solutions - November ...

SIMATIC ET 200 - For distributed automation solutions - November ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

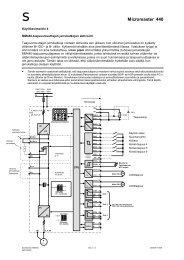

© Siemens AG 2010EngineeringMaximum engineering efficiency –in all phases of the lifecycle of the machine and plantStandardized design and engineering …… for all <strong>automation</strong> componentsOperationsmanagement levelEngineering Station<strong>SIMATIC</strong> WinCCControl levelPROFIN<strong>ET</strong>Industrial EthernetProject databaseDigital Engineering• <strong>SIMATIC</strong> Automation DesignerEngineering Software• <strong>SIMATIC</strong> STEP 7• <strong>SIMATIC</strong> WinCC / WinCC flexibleField levelHMIPROFIBUSControllerDrivesDistributed IOWith <strong>SIMATIC</strong> you rely on an integrated engineering environment.Efficient software supports you over thecomplete lifecycle of your machine or plant – from theplanning and design stages through configuring andprogramming as far as commissioning, operation andupgrading.With its integration capability and harmonized interfaces,<strong>SIMATIC</strong> software permits a high degree of dataconsistency – throughout the entire engineering process.Data consistency in the entire project• Variables only have to be entered and configured inone editor• Project-wide synchronizationModularity through blocks• Program sections and user interfaces can be createdmodularly as reusable blocks• Program modules can be loaded into the <strong>automation</strong>system during operation• In addition, expansions and changes to the hardwareconfiguration are possible during operationShared configuration for the complete <strong>automation</strong>hardware• Shared hardware configuration• Shared network configurationOpen data interfaces• Third-party components can be incorporated basedon GSD/EDD• Import/export interfaces permit data exchange withthird-party software (MS Excel)• Data transfer from planning software – e.g. fromelectrical engineering department (CAE)• Ability to incorporate Visual Basic scripts for furtherprocessingData archiving• All data, hardware configuration data, programs,user interfaces are saved and archived in one projectMultilingual/internationality• The user interface of many software packages isavailable in six or more languages• The interfaces of the HMI devices (operator panels)can be created in various languages, even duringoperation – as can the program comments within<strong>SIMATIC</strong> STEP 7Standard programming languages• Six PLCopen or IEC 61131-3-compliant programminglanguages• PLCopen-certified motion control blocks8 System features