SIMATIC ET 200 - For distributed automation solutions - November ...

SIMATIC ET 200 - For distributed automation solutions - November ...

SIMATIC ET 200 - For distributed automation solutions - November ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

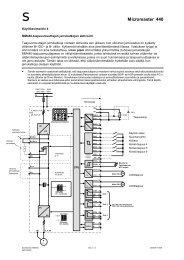

© Siemens AG 2010<strong>SIMATIC</strong> <strong>ET</strong> <strong>200</strong>eco PNStihl Andreas AG & Co KG, Germany –Production of chain sawsRequirementsStihl in Waiblingen/Germany is one of the leading manufacturersof chain saws and equipment for greenspace and forestmaintenance. Stihl chain saws combine innovative technology,high performance, optimum ergonomics and low weight,mainly through different equipment variants for any application.This requires modern and highly flexible manufacturingplants. With proprietary equipment production and highlyqualified and specialized personnel, Stihl is able to equip itsown manufacturing and assembly facilities.That is why the <strong>automation</strong> specialists are extremely interestedin innovative and lasting <strong>automation</strong> <strong>solutions</strong>. To simplifyhandling and to make maintenance/adjustment as efficient aspossible, a uniform solution with a minimum of engineeringtools is required. To protect investments on a long-term basis,Stihl places great emphasis on long-lasting <strong>solutions</strong>.SolutionIn the newly installed assembly line (50 m long), differentchain saw variants are produced flexibly, from the chassisthrough the assembly up to final inspection and testing. At thebeginning, a manufacturing data set consisting of up to 20variants is assigned to each mounting structure. An uncodedRFID chip which stores the manufacturing data is attached tothe mounting structure for this purpose.Via Pick to Light, the mounting structure is thus uniquely identifiedat RFID reading stations during the complete manufacturingprocess and is read in directly at the machine via<strong>ET</strong> <strong>200</strong>eco PN IO-Link Master. Furthermore, the productionsteps are visualized and controlled at mobile panels (<strong>SIMATIC</strong>Mobile Panel 277 IWLAN) throughout the entire assembly linevia Industrial Wireless LAN (IWLAN).BenefitsThrough the use of the flexible and rugged <strong>ET</strong> <strong>200</strong>eco PN, thedata can be bundled directly at the RFID reader and, via standardPROFIN<strong>ET</strong> protocols, sent directly to the CPU for furtherprocessing. Integrated tools, such as the Port ConfiguratorTool (PCT) for IO-Link, have also made maintenance very easy,since replacement IO-Link Master modules receive their addresseswithout any configuration overhead and are then immediatelyready for operation, with the result that "the modulesof <strong>SIMATIC</strong> <strong>ET</strong> <strong>200</strong>eco PN do not have to be addressed atall, neither during installation nor during replacement in theevent of a failure", says Michael Muerdter, <strong>automation</strong> expertat Stihl. Faults are detected at an early stage via the integrateddiagnostics, indicated on the visual display device and remediedbefore any significant failure occurs. Costs can thus be reducedin the long term and downtimes minimized.References 61