SIMATIC ET 200 - For distributed automation solutions - November ...

SIMATIC ET 200 - For distributed automation solutions - November ...

SIMATIC ET 200 - For distributed automation solutions - November ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

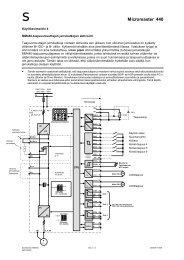

© Siemens AG 2010<strong>SIMATIC</strong> <strong>ET</strong> <strong>200</strong>S COMPACTMeyer Burger AG, Switzerland –Manufacturing and processing of materialsRequirementsMeyer Burger AG has over 50 years of experience in cuttinghard and brittle materials and special crystals such as siliconand sapphire. The global sales and service network of MeyerBurger has a separate subsidiary in China and Japan as well asservice centers in Germany and the Philippines. The main industriesare the photovoltaic, semiconductor and optical andceramics industries. More than 3,500 systems have been installedworldwide.Hard and brittle materials have to be cut faster, more accuratelyand with less loss of material. This places stringent demandson the control system and the I/O: Compact size, fastresponse, reduced wiring outlay and modular construction ofmachines.SolutionTo meet these requirements, Meyer Burger relies on the compact<strong>distributed</strong> I/O <strong>ET</strong> <strong>200</strong>S COMPACT. Thanks to their highchannel density, it was not necessary to expand the stations.Add-on terminals were also used to enable 3-wire connectionwithout the need for additional terminal blocks. This savesspace and time during wiring up. The existing bus system wasPROFIBUS DP, so this was also used for the new solution.BenefitsThe use of <strong>ET</strong> <strong>200</strong>S COMPACT provides several benefits: Thesignals of the different sensors and switches can now be bundledand evaluated by the existing PROFIBUS. Complete preassembly(wiring) of the modules means that on final installationonly the bus cable has to be connected. Time-consumingwiring of modules in the control cabinet is therefore reduced."By using <strong>ET</strong> <strong>200</strong>S COMPACT, we can acquire control variableson our machines decentralized and transfer them to the controllerover PROFIBUS. Fewer signals therefore have to berouted to the control cabinet. This reduces the wiring costsand increases our flexibility considerably. We can thereforereduce throughput time at final assembly."Dr. Urs Schönholzer,Head of DevelopmentReferences 57