SIMATIC ET 200 - For distributed automation solutions - November ...

SIMATIC ET 200 - For distributed automation solutions - November ...

SIMATIC ET 200 - For distributed automation solutions - November ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

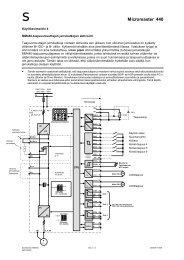

© Siemens AG 2010PROFIN<strong>ET</strong> innovationsNEWPROFIN<strong>ET</strong> has been expanded by a number of innovativefeatures. These simplify system configuration in fail-safeapplications, for example, and they allow a leaner andmore versatile topology in many different scenarios.<strong>SIMATIC</strong> <strong>ET</strong> <strong>200</strong>proTwo controllers can access the same PROFIN<strong>ET</strong> IO-Device,such as a <strong>distributed</strong> <strong>ET</strong> <strong>200</strong>, using the function Shared Device.Since fewer remote devices have to be installed in thefield, engineering, cabling and installation costs are reduced.In addition, the modules can be flexibly assigned to one of thetwo CPUs.<strong>SIMATIC</strong> S7-300Ring(MRP)<strong>SIMATIC</strong> S7-400IO-Controller 1IO-Controller 2PROFIN<strong>ET</strong>Industrial Ethernet<strong>SIMATIC</strong> <strong>ET</strong> <strong>200</strong>Ring topology with Media Redundancy Protocol (MRP)PROFIN<strong>ET</strong>Industrial EthernetGreater plant availability can be achieved with the help of aring topology and the Media Redundancy Protocol (MRP).This runs direct via the integral PROFIN<strong>ET</strong> port to <strong>SIMATIC</strong> controllersand <strong>ET</strong> <strong>200</strong> IO stations and can be used with or withoutIE switches.IO-DeviceWith the Shared Device function, two different IO controllers can access thesame IO device simultaneouslyThe function I-Device (intelligent IO-Device) enables simpleand fast controller-controller communication through directaccess to the IO address image with PROFIN<strong>ET</strong> IO protocol.Local controllers, such as the <strong>ET</strong> <strong>200</strong>S CPU, can be more easilyintegrated into modular machines or safety applications, forexample.PROFIN<strong>ET</strong> systems with the innovative PROFIenergy profileare able to control energy consumption. They can be configuredin such a way that they can be disconnected automaticallyand in a coordinated way during breaks in production, andthen connected again when production starts up again – inthe correct order, at the correct intervals, reliably and plantwide.Additional expanded functionsThe <strong>ET</strong> <strong>200</strong>S supports the Options handling function. Withthis, an application can be subdivided into several modules orsub-tasks (e.g. bottling, labeling, packaging), without theneed to manage several projects for different machine constellations.In the <strong>ET</strong> <strong>200</strong>S station, the input/output modulesare assigned to the appropriate sub-tasks. The actually availablemachine modules or the input/output modules of the<strong>ET</strong> <strong>200</strong> station required for this are selected and activated atcommissioning.PROFIN<strong>ET</strong> IRT and isochronous mode allow high-speed anddeterministic communication in which the different cycles ofa system (input, remote station, network, CPU processing andoutput) are synchronized even in the case of parallel TCP/IPtraffic. High-precision and dynamic applications can thus beimplemented using <strong>SIMATIC</strong>.24<strong>ET</strong> <strong>200</strong> – features