SIMATIC ET 200 - For distributed automation solutions - November ...

SIMATIC ET 200 - For distributed automation solutions - November ...

SIMATIC ET 200 - For distributed automation solutions - November ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

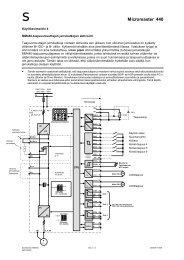

© Siemens AG 2010<strong>SIMATIC</strong> <strong>ET</strong> <strong>200</strong>pro with Safety Integrated and PROFIN<strong>ET</strong>Volkswagen Nutzfahrzeuge, Germany –Vibrating roller test bedRequirementsVolkswagen Nutzfahrzeuge (VWN), an autonomous brand ofthe Volkswagen corporation has installed the final noise testin the transporter works in Hanover in the workshop hall. Nowthe commercial vehicle business is operating a vibrating rollertest bed in its works in Hanover in cooperation with the "AutomationInitiative of the German Automotive Industry" (AIDA).The customer's requirements were extensive: The vibratingroller test bed had to be linked into the existing network structure(PROFIN<strong>ET</strong>); fail-safe communication was just as importantas a reduction in training costs. The use of <strong>distributed</strong> I/Owas also demanded.SolutionThe <strong>distributed</strong> I/O had to be installed in the support structureof the test bed, in a compact space, close to the vibrationdampers. Therefore the only solution was a cabinet-free solutionof extremely high ruggedness and industrial compatibility,which is why <strong>SIMATIC</strong> <strong>ET</strong> <strong>200</strong>pro was used.An S7-400F controller was used which ensured fail-safe communicationover PROFIN<strong>ET</strong>. Apart from the cabinet-free<strong>SIMATIC</strong> <strong>ET</strong> <strong>200</strong>pro, the <strong>SIMATIC</strong> <strong>ET</strong> <strong>200</strong>S – which was installedin the control cabinet alongside the controller – wasalso used as <strong>distributed</strong> I/O. Both <strong>distributed</strong> I/O systems are ina standard but fail-safe configuration. A PROFIN<strong>ET</strong>-capableSCALANCE X208pro switch with IP65 degree of protection distributesincoming and outgoing data.BenefitsUse of <strong>SIMATIC</strong> <strong>ET</strong> <strong>200</strong>pro resulted in a number of advantages:Costs were saved thanks to standardization and optimizationof the spare parts inventory. The reduction in training costs formaintenance and service personnel was also satisfied. Due tothe ability to replace electronic modules during operation (hotswapping), high availability was achieved for the plant. Therewas also a reduction in the installation and wiring costs for thesafety-related part of the plant.60References