Applied Superconductivity - Walther Meißner Institut - Bayerische ...

Applied Superconductivity - Walther Meißner Institut - Bayerische ...

Applied Superconductivity - Walther Meißner Institut - Bayerische ...

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

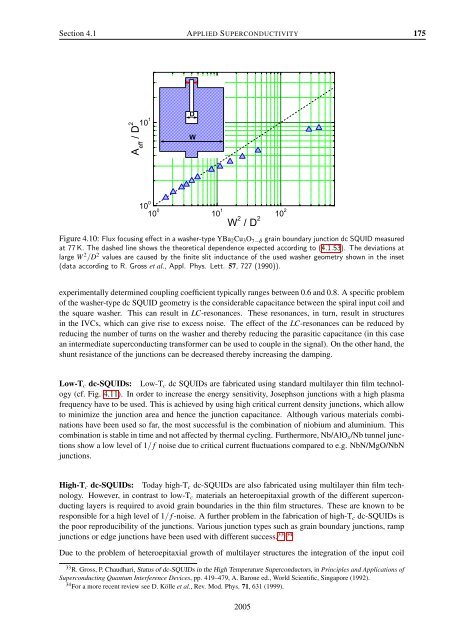

Section 4.1 APPLIED SUPERCONDUCTIVITY 175A eff/ D 210 1DW10 010 0 10 1 10 2W 2 / D 2Figure 4.10: Flux focusing effect in a washer-type YBa 2 Cu 3 O 7−δ grain boundary junction dc SQUID measuredat 77 K. The dashed line shows the theoretical dependence expected according to (4.1.53). The deviations atlarge W 2 /D 2 values are caused by the finite slit inductance of the used washer geometry shown in the inset(data according to R. Gross et al., Appl. Phys. Lett. 57, 727 (1990)).experimentally determined coupling coefficient typically ranges between 0.6 and 0.8. A specific problemof the washer-type dc SQUID geometry is the considerable capacitance between the spiral input coil andthe square washer. This can result in LC-resonances. These resonances, in turn, result in structuresin the IVCs, which can give rise to excess noise. The effect of the LC-resonances can be reduced byreducing the number of turns on the washer and thereby reducing the parasitic capacitance (in this casean intermediate superconducting transformer can be used to couple in the signal). On the other hand, theshunt resistance of the junctions can be decreased thereby increasing the damping.Low-T c dc-SQUIDs: Low-T c dc SQUIDs are fabricated using standard multilayer thin film technology(cf. Fig. 4.11). In order to increase the energy sensitivity, Josephson junctions with a high plasmafrequency have to be used. This is achieved by using high critical current density junctions, which allowto minimize the junction area and hence the junction capacitance. Although various materials combinationshave been used so far, the most successful is the combination of niobium and aluminium. Thiscombination is stable in time and not affected by thermal cycling. Furthermore, Nb/AlO x /Nb tunnel junctionsshow a low level of 1/ f noise due to critical current fluctuations compared to e.g. NbN/MgO/NbNjunctions.High-T c dc-SQUIDs: Today high-T c dc-SQUIDs are also fabricated using multilayer thin film technology.However, in contrast to low-T c materials an heteroepitaxial growth of the different superconductinglayers is required to avoid grain boundaries in the thin film structures. These are known to beresponsible for a high level of 1/ f -noise. A further problem in the fabrication of high-T c dc-SQUIDs isthe poor reproducibility of the junctions. Various junction types such as grain boundary junctions, rampjunctions or edge junctions have been used with different success. 33,34Due to the problem of heteroepitaxial growth of multilayer structures the integration of the input coil33 R. Gross, P. Chaudhari, Status of dc-SQUIDs in the High Temperature Superconductors, in Principles and Applications ofSuperconducting Quantum Interference Devices, pp. 419–479, A. Barone ed., World Scientific, Singapore (1992).34 For a more recent review see D. Kölle et al., Rev. Mod. Phys. 71, 631 (1999).2005